Intelligent prestressing force stretching system

An intelligent tensioning and prestressing technology, applied to fluid pressure actuation system components, fluid pressure actuation devices, rails, etc., can solve problems such as large reading errors, complicated operating procedures, and slow measurement processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing example, the present invention is described in further detail:

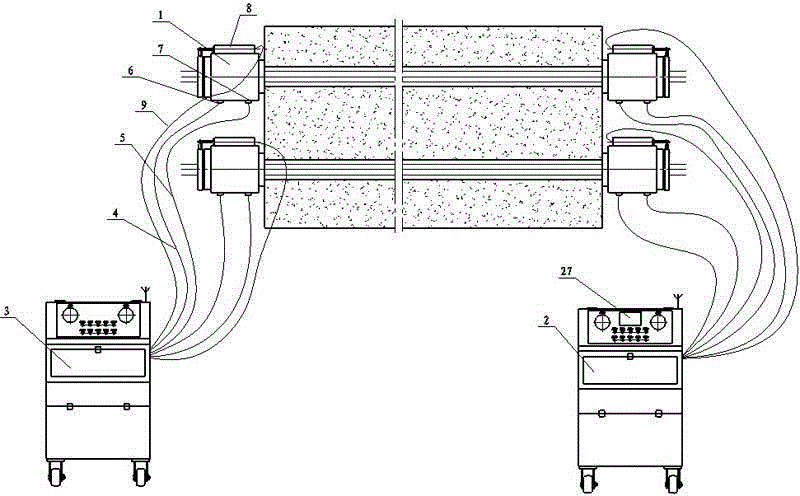

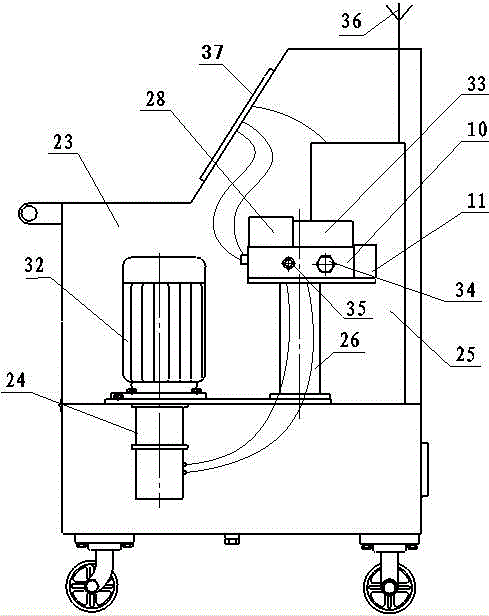

[0020] Such as figure 1 The present invention shown, it comprises intelligent tensioning jack 1 and a main pulling pumping station 2 and secondary tensioning pumping station 3, main pulling pumping station is provided with display screen, and this display screen is man-machine interface touch screen 27, and main pulling pumping station 2 and sub-tensioning pumping station 3 are respectively connected to oil return port 6 and oil inlet 7 of intelligent tensioning jack 1 through high-pressure oil pipes 4 and 5; The data line 9 of the system is electrically connected with the displacement sensor 8 of the intelligent tension jack 1 .

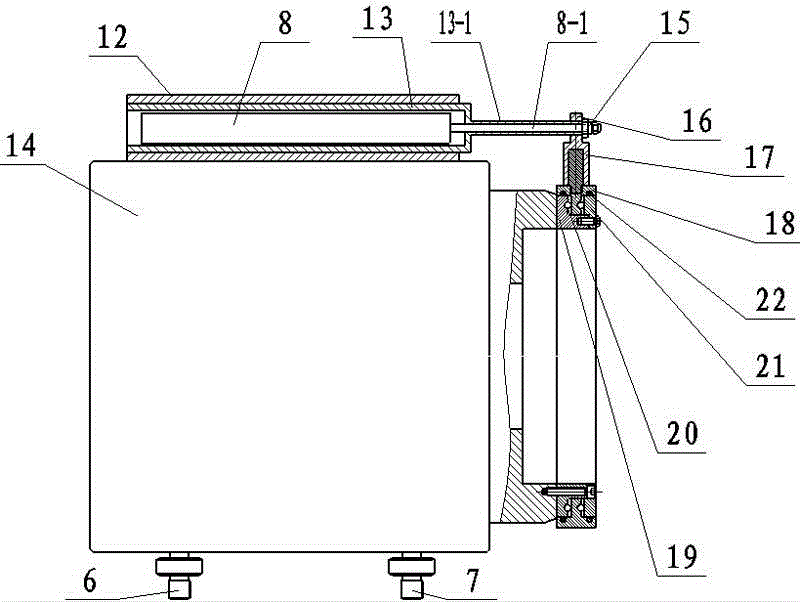

[0021] Such as figure 2 As shown, the intelligent tensioning jack 1 includes a through-type jack, the displacement sensor 8 is installed in the linear guide device on the through-type jack, and one end of the displacement sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com