LED (light-emitting diode) display screen box body

A technology of LED display screen and cabinet, applied in the direction of cabinet/cabinet/drawer parts, instruments, identification devices, etc., can solve large gaps, it is difficult to ensure the bending angle of the cabinet, and it cannot meet the needs of high-end users. requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments and with reference to the accompanying drawings.

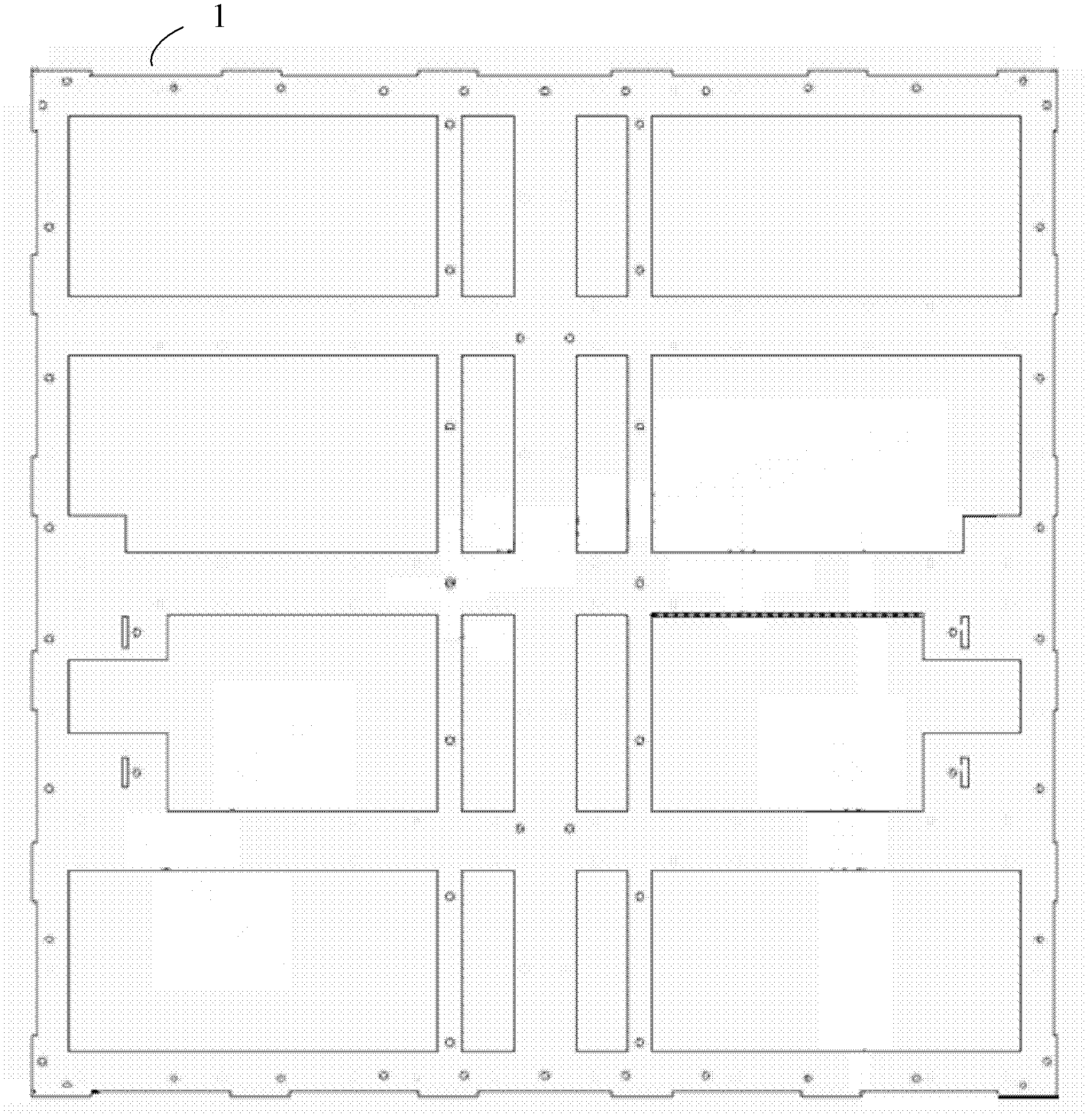

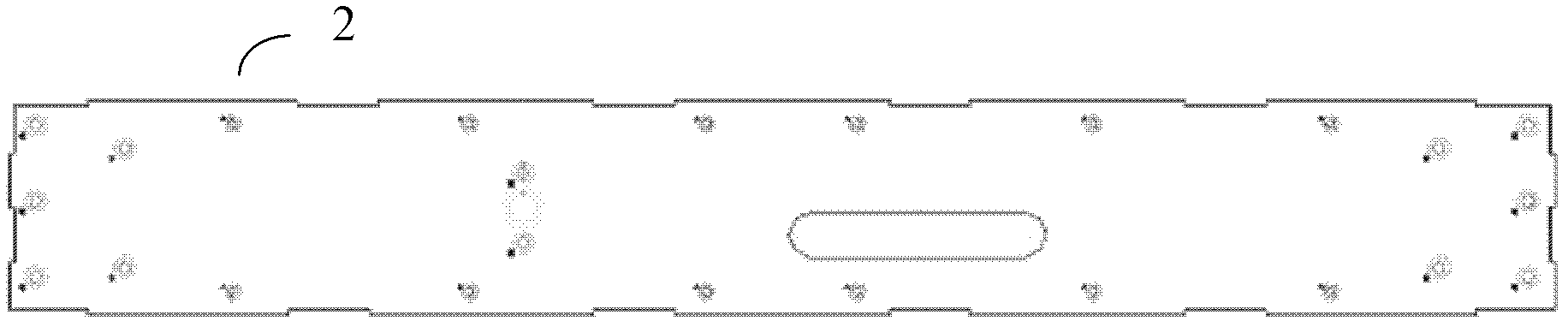

[0026] In the present invention, the front panel refers to the metal panel used to install the LED display in the cabinet, and the rear panel refers to the metal panel opposite to the metal panel for installing the LED display in the cabinet. The panels on the left and right sides of the front panel are left The side panel and the right side panel, the upper and lower sides are the top panel and the bottom panel. Preferably, the front and rear panels are made into symmetrical shapes and structures, the left and right panels are made into symmetrical shapes and structures, and the upper and lower panels are made into symmetrical shapes and structures. Apparently, the six panels in the present invention, especially the panels other than the front and rear panels, can be made with the same shape and structure or different sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com