Simultaneous multi-gear meshing transmission of composite hydraulic torque converter

A torque converter and compound fluid technology, applied in the field of multi-gear simultaneous meshing transmissions, can solve the problems of low transmission efficiency, complex structure, troublesome operation, etc., and achieve the effects of protecting the environment, reducing manufacturing costs, and being easy to maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

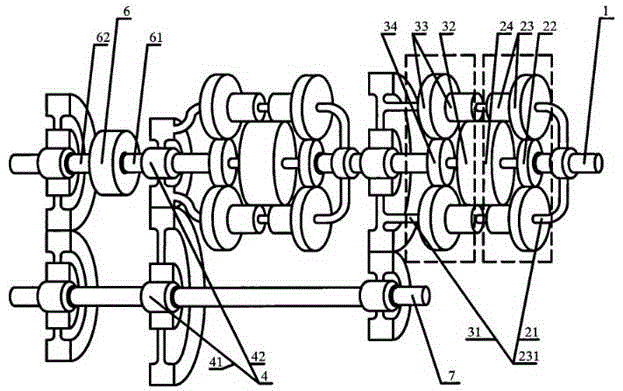

[0020] like figure 1 As shown in , a multi-gear simultaneous meshing transmission of a compound hydraulic torque converter, it includes an input shaft 1, a transmission mechanism 4, a coupling 6, an output shaft 7, the output end 62 of the coupling 6 is matched with the transmission The input end 41 of the mechanism 4 is connected, the output end 42 of each transmission mechanism 4 is connected with the output shaft 7, and two torque increasing units 2 and two speed regulating units 3 are arranged between the input shaft 1 and the output shaft 7. The torque booster unit 2 includes an output element 21, an input element 22, a planetary gear 23, and a coupling element 24. The speed regulating unit 3 includes an output element 31, an input element 32, a planetary gear 33, and a coupling element 34. The first torque booster unit The input element 22 of 2 is connected with the input shaft 1, and the input elements 22 of the other torque boosting units 2 are connected with the coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com