Comprehensive test instrument for testing multi-path conducting wire\connector

A comprehensive tester and connector technology, applied in the field of testing instruments and comprehensive testers, can solve the problems of lack of test data storage, statistics, output, printing, inability to use network remote control, heavy workload, etc., to achieve safe authority Management ability, friendly man-machine interface, and the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

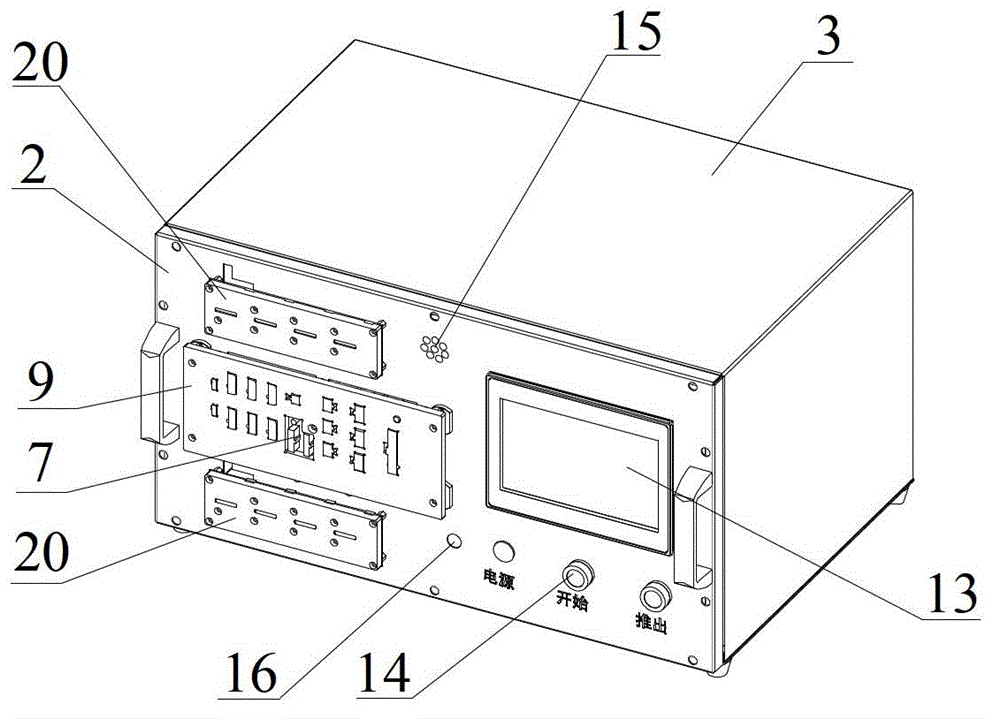

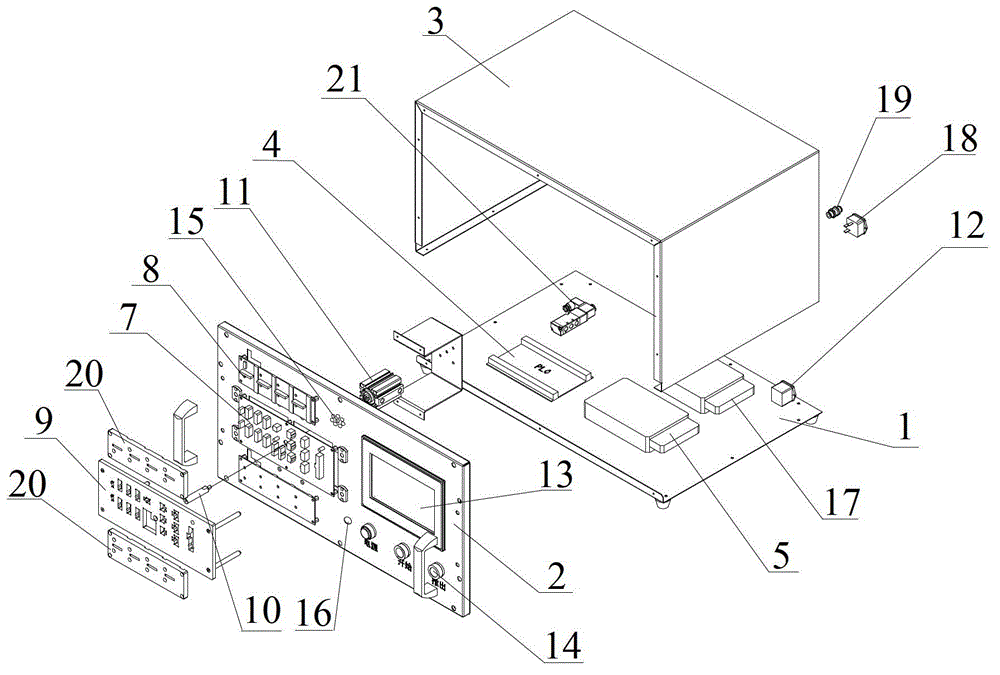

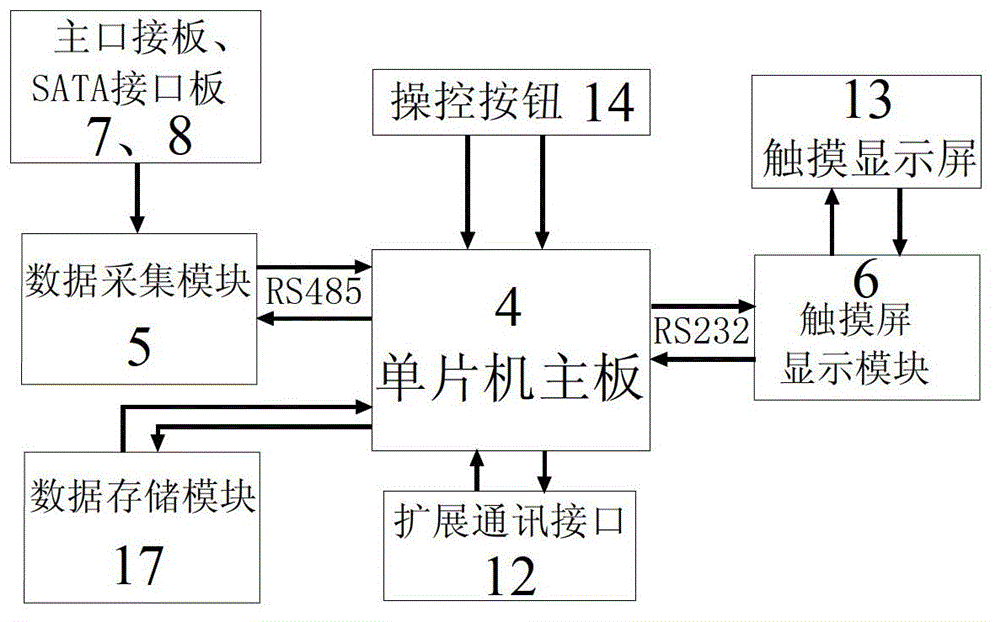

[0029] A comprehensive tester for multi-channel wire\connector testing, such as figure 1 , figure 2 with image 3 As shown, it has a tester body composed of a mounting base plate 1 equipped with a printed circuit board, a control panel 2 and a cover 3. The printed circuit board of the mounting base plate 1 is respectively equipped with a single-chip main board 4 and a data acquisition module. 5. The single-chip main board 4 is respectively connected with the data acquisition module 5 and the touch screen display module 6 installed on the control panel 2 via the RS232 / RS485 communication interface, and the data acquisition module 5 is connected with the main interface board 7 provided on the control panel 2 Connect with the wire of SATA interface board 8, the wire / connector push plate 9 that is provided with at the front end of main interfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com