A kind of backlight dimming circuit and its dimming method, liquid crystal display

A dimming circuit and backlight technology, applied in static indicators, instruments, etc., can solve the problems of complex algorithm and timing control, increase the cost of the whole machine, etc., to reduce backlight power consumption, promote energy saving, and reduce data conversion and data. The effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

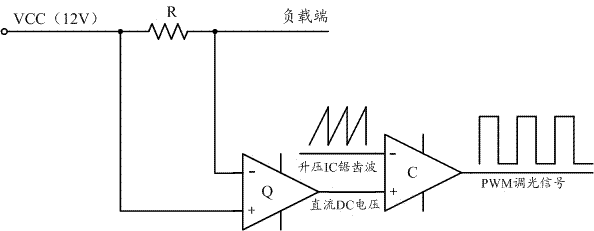

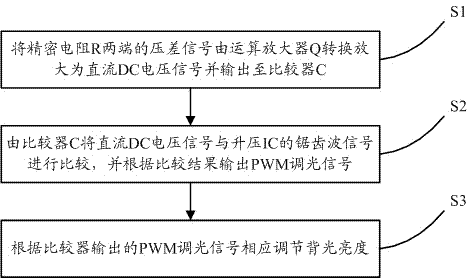

[0034] Specifically, a backlight dimming circuit according to an embodiment of the present invention includes:

[0035] The power supply voltage terminal VCC is used to provide a power supply voltage;

[0036] Operational amplifier Q, its non-inverting input terminal is connected to the power supply voltage terminal VCC, and its inverting input terminal is connected to the load terminal;

[0037] The precision resistor R is connected between the non-inverting input terminal and the inverting input terminal of the operational amplifier Q, and the voltage difference signal across the precision resistor R is converted and amplified by the operational amplifier Q into a DC voltage signal and output;

[0038] Comparator C, its non-inverting input terminal receives the DC voltage signal output by the operational amplifier Q, and its inverting input terminal receives the sawtooth signal from the boost IC in the boost converter, which is used to combine the DC voltage signal with the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap