Self-tightening sealed structure for refueling water level control of reactor

A self-tightening sealing and water level control technology, applied in the fields of reactors, sealing, nuclear power generation, etc., can solve the problems of inability to meet the functional requirements of supercritical water-cooled reactors, harsh operating conditions, and lack of mature materials, so as to improve reliability. and service life, reducing economic costs, reducing the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is a further introduction of a reactor self-tightening seal refueling water level control structure provided by the present invention in conjunction with the accompanying drawings and specific implementation methods:

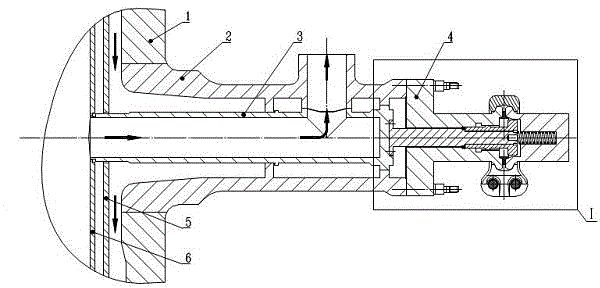

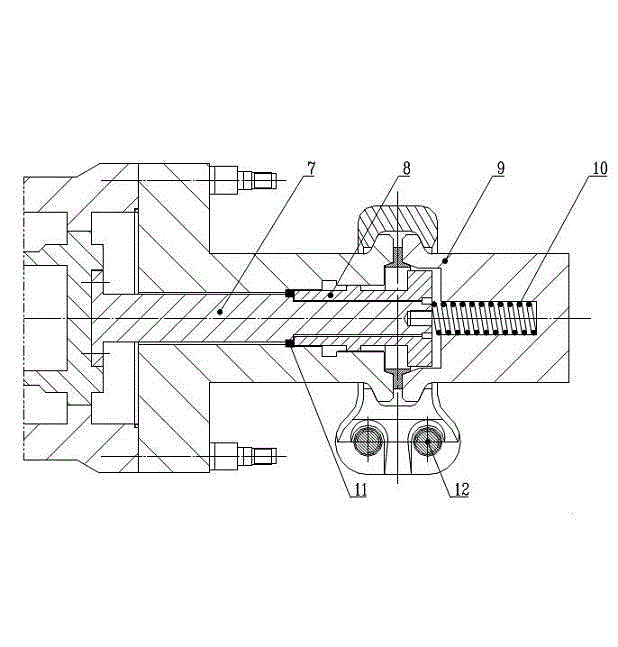

[0017] as attached figure 1 As shown, the reactor self-tightening and sealing refueling water level control structure includes the heat-insulating lining sleeve 3 arranged in the outlet connecting pipe 2, and the outlet connecting pipe 2 and the heat-insulating lining casing 3 are arranged on the reactor core hanging basket 5 , as the core fluid outlet. The end of the heat insulation lining sleeve 3 inserted into the core basket 5 is the open end, and the end far away from the core suspension basket 5 is the closed end. Before the closed end, the heat insulation lining sleeve 3 has an opening with the outlet connecting pipe 2 Corresponding openings for reactor core fluid to flow into the main piping, if attached figure 1 The direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com