Molded carrier for moving on an assembly line

A technology of molding and supporting parts, which is applied in the directions of motor vehicles, manufacturing tools, transportation and packaging, etc., can solve the problems of inaccurate positioning devices, and achieve the effect of low-cost and accurate positioning devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

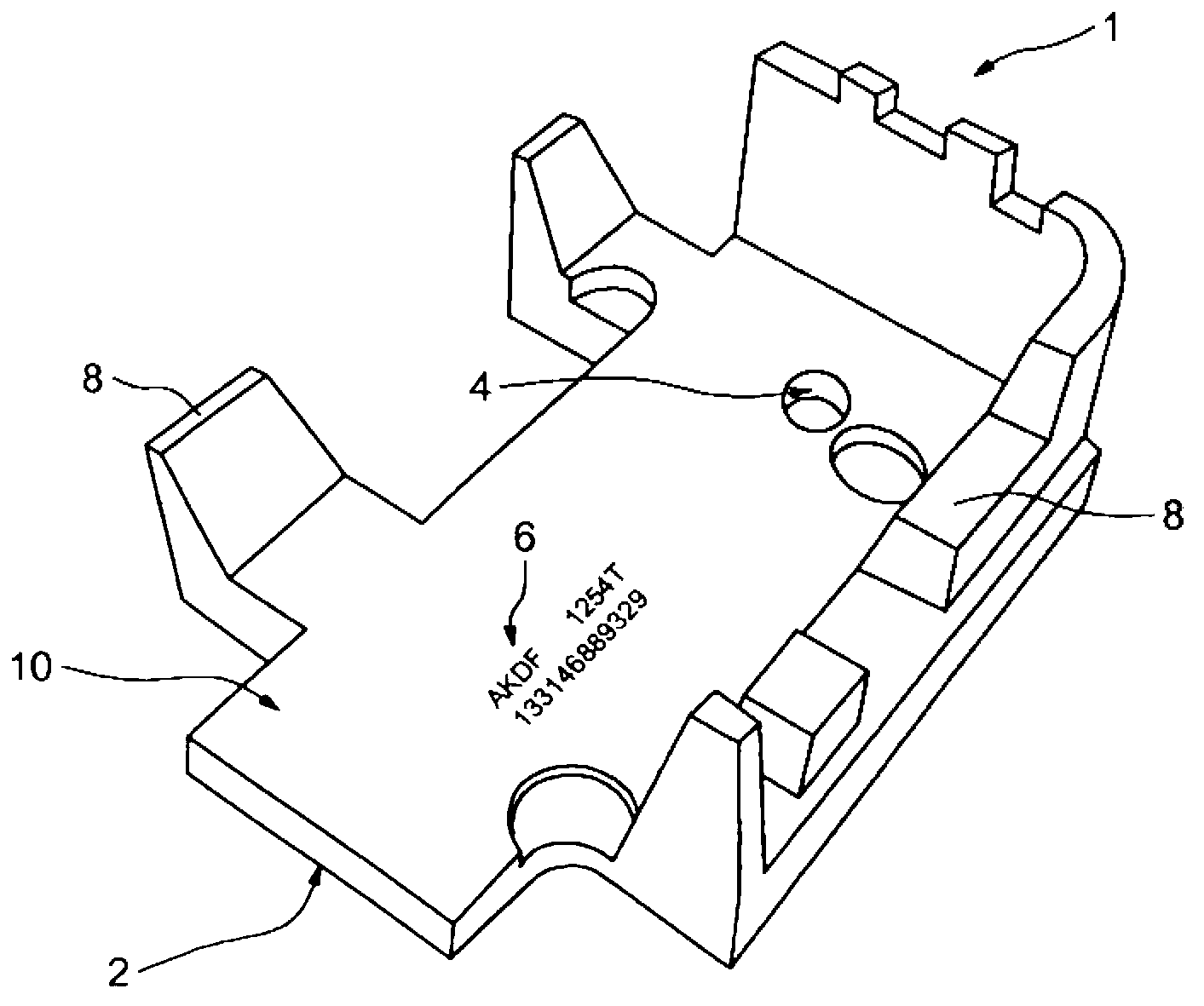

[0027] figure 1 Shown is a support 1 made by molding of plastics material, comprising a lower surface 2 resting on a base plate, not shown, which is moved by a loading and unloading chain of an assembly line.

[0028] The lower surface 2 comprises a hole 4 realized when the support 1 is molded, in which hole a pin fixed to the base plate is fitted, said pin comprising an upper end terminating in a conical portion. In order to position the support 1 on the base plate without stress, it is possible in particular to place a pin forming a centering device, and a further pin fitted in an oblong shape, the axis of which essentially rotates towards this centering device , to carry out the orientation of the support around the centering device.

[0029] The periphery of the upper surface 10 of the support 1 comprises bosses 8 of different heights, the upper part of which comprises inwardly inclined ramps constituting a mount for receiving the internal combustion engine of the motor v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com