Device for thermally treating multiple threads

A technology of heating device and silk thread, which is applied in the direction of textiles and paper making, can solve the problems of energy loss and achieve the effect of short suction stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

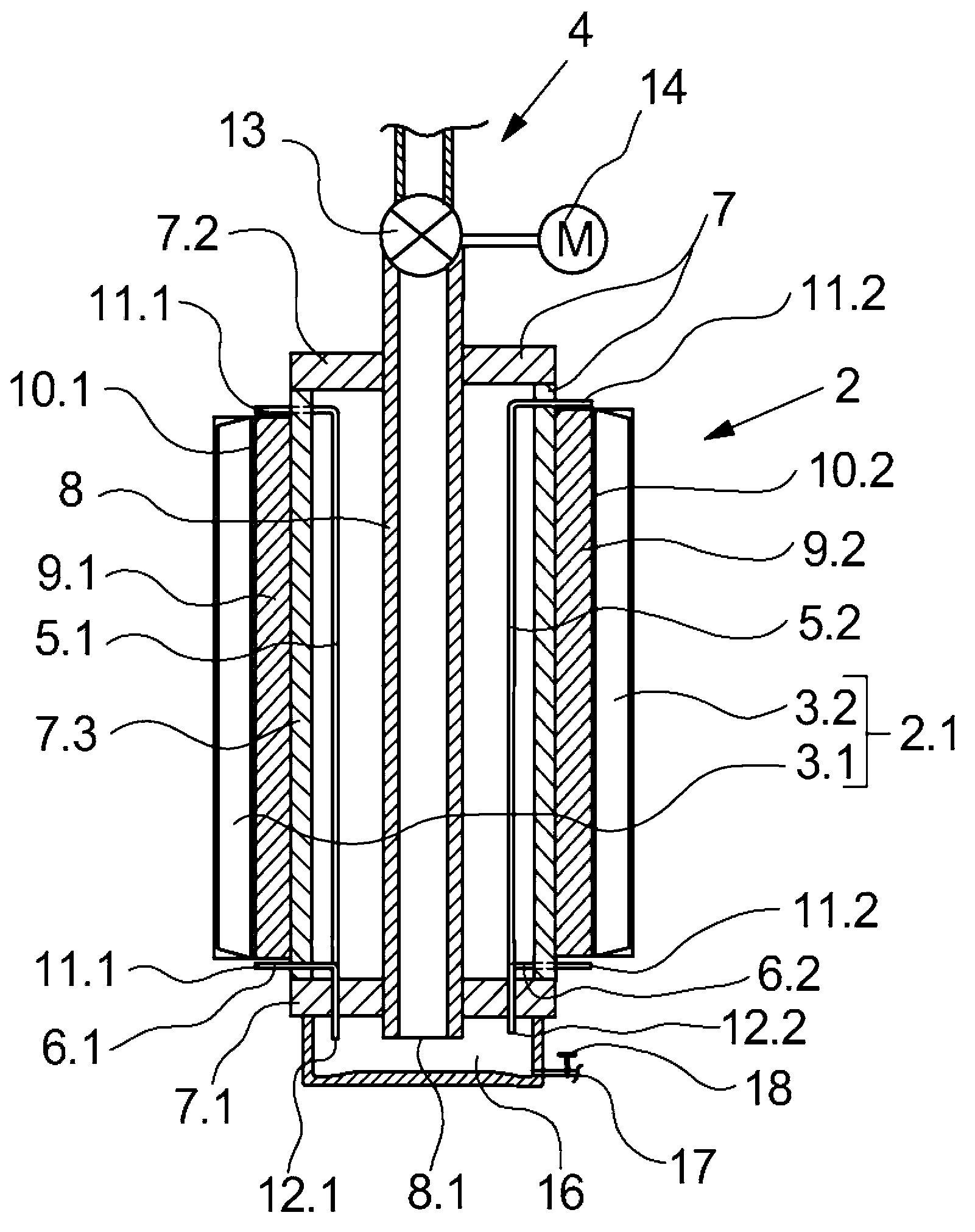

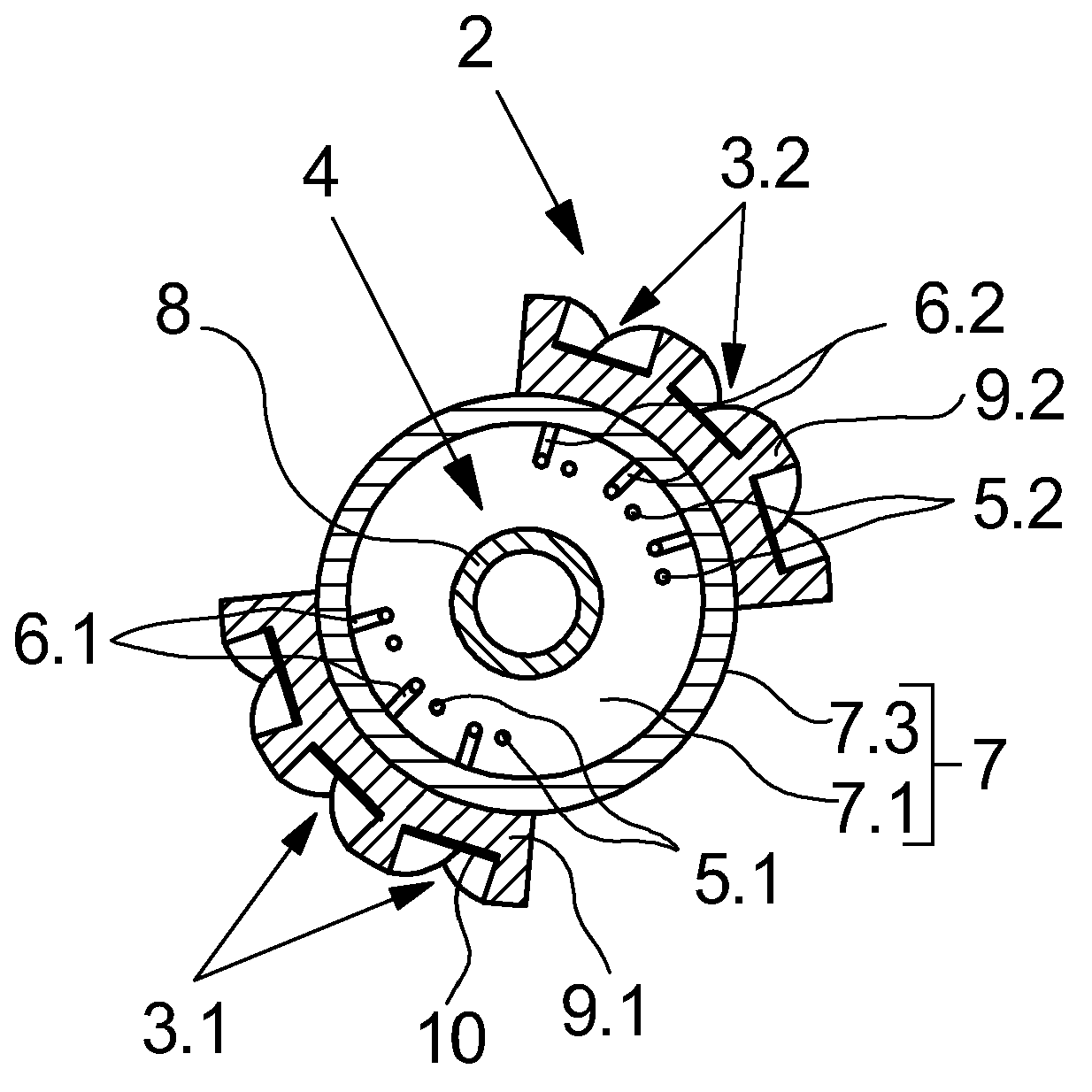

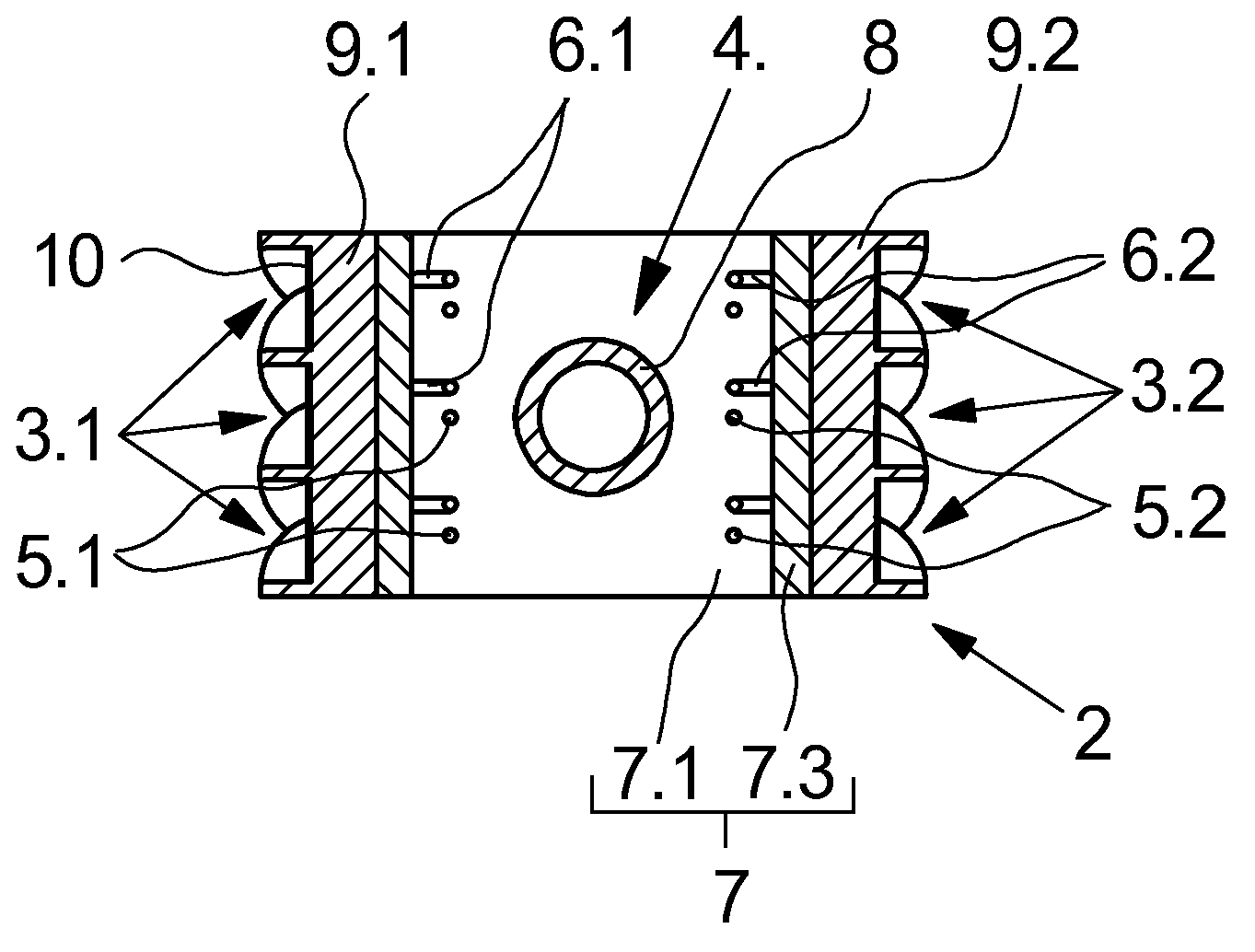

[0024] figure 1 and 2 A first embodiment of a device for thermally treating a plurality of wires according to the invention is shown in . exist figure 1 A longitudinal section is schematically shown in and in figure 2 A schematic cross-sectional view is shown in . The following description applies to both figures as long as one of the two figures is not explicitly referenced.

[0025] In the illustration of the device according to the invention, only components relevant to the invention are shown for the sake of clarity. In particular, insulation and coverings are de-shown.

[0026] according to figure 1 and 2 The exemplary embodiment of FIG. 1 shows a structural unit 1 with a support 7 for receiving the heating device 2 and the suction device 4 . In this exemplary embodiment, the support 7 is formed by a lower plate 7.1 and an upper plate 7.2, which are connected via elongated struts 7.3. In this exemplary embodiment, the strut 7.3 has a tubular design and has two o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com