Liquid crystal display device and method for manufacturing liquid crystal display device

A technology of liquid crystal display device and manufacturing method, which is applied in the direction of chemical instruments and methods, liquid crystal materials, instruments, etc., and can solve the problems such as the decrease of white display transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0102] The liquid crystal display device according to Embodiment 1 is a display device including a liquid crystal cell, and can be suitably used for TV panels, digital signage, medical monitors, electronic books, PC monitors, portable terminal panels, and the like.

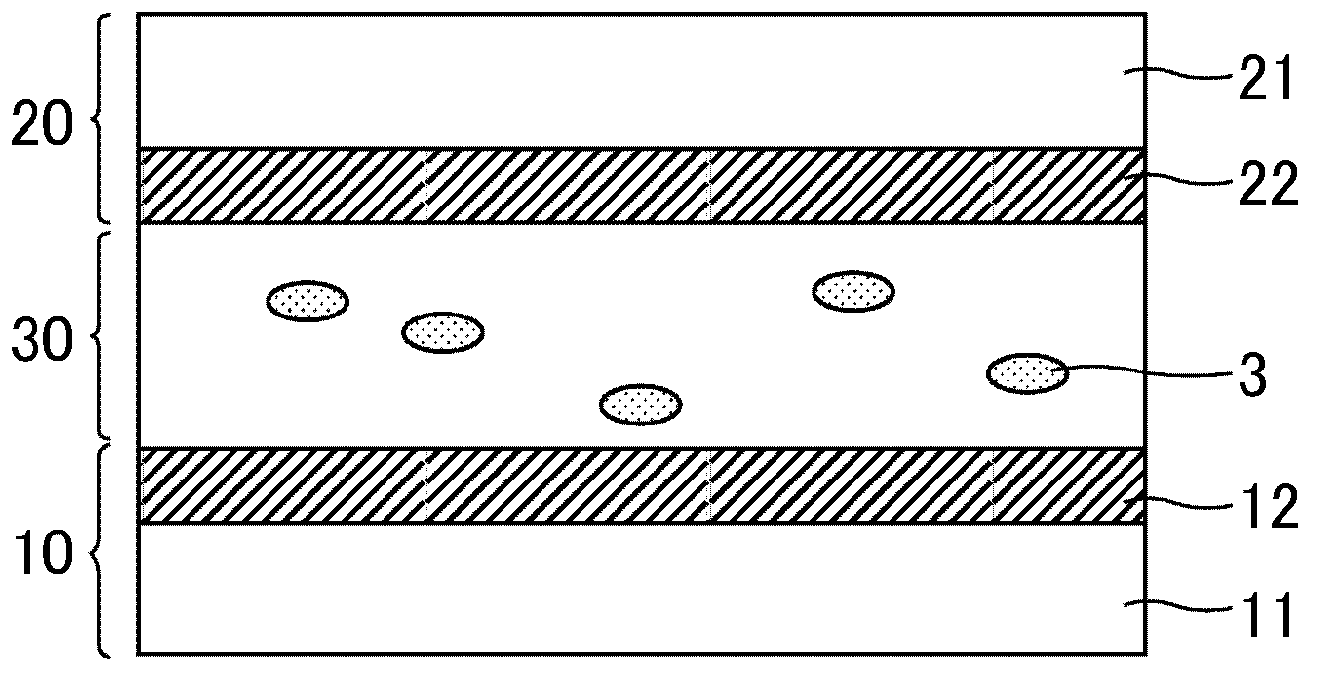

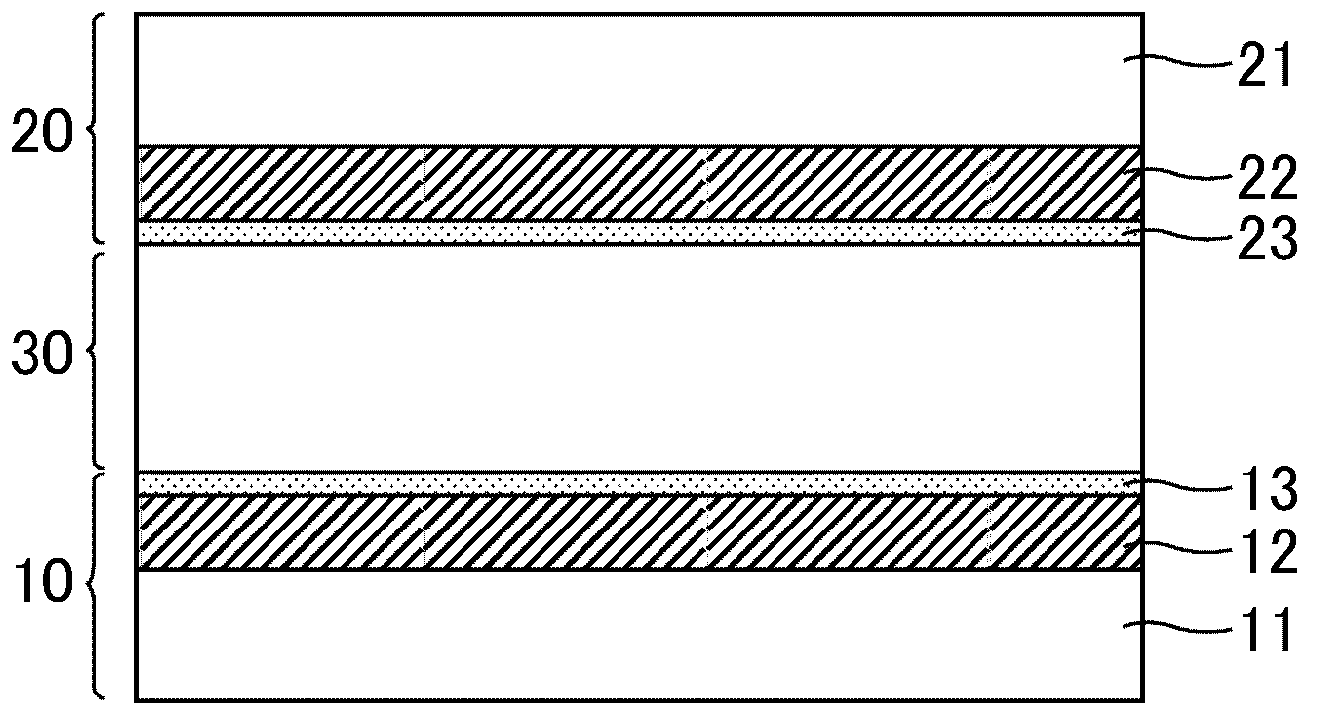

[0103] Hereinafter, the liquid crystal display device of Embodiment 1 will be described in detail. figure 1 and figure 2 is a schematic cross-sectional view of the liquid crystal display device according to the first embodiment. figure 1 Indicates that before the PS polymerization process, figure 2 Indicates after the PS polymerization step. Such as figure 1 and figure 2 As shown, the liquid crystal display device of Embodiment 1 includes: an array substrate 10 ; a color filter substrate 20 ; and a liquid crystal layer 30 sandwiched between a pair of substrates composed of the array substrate 10 and the color filter substrate 20 . The array substrate 10 has an insulating transparent substrate 11 made of...

Embodiment 1

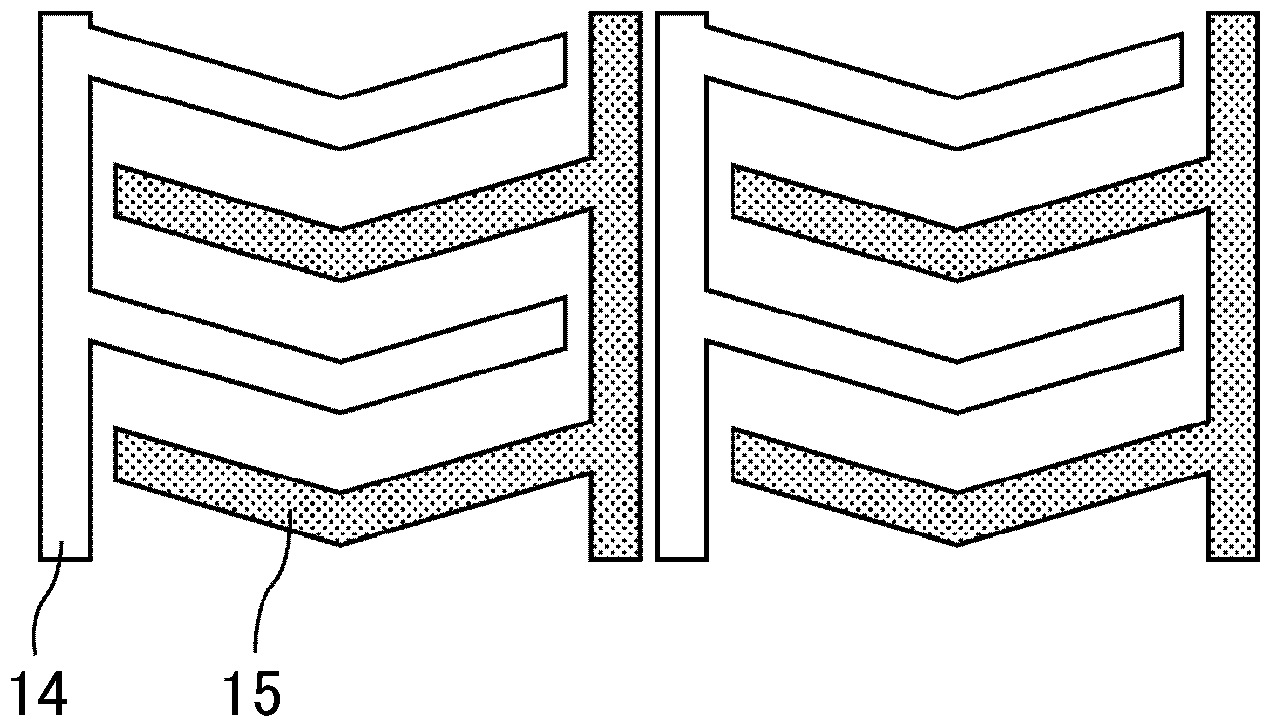

[0156] A glass substrate having a pair of comb-teeth electrodes as transparent electrodes (hereinafter, collectively referred to as a comb-teeth electrode substrate) and a bare glass substrate (counter substrate) were prepared, and each substrate was coated by spin coating as The polyvinyl cinnamate solution of the material of the horizontal alignment film. Figure 6 It is a schematic plan view showing the comb-shaped electrode substrate of Example 1. Glass used #1737 (manufactured by Corning Incorporated). Comb electrodes, when viewed roughly, as Figure 6 As shown, the common electrode 71 and the signal electrode 72 extend substantially parallel to each other and are formed in a meandering manner. As a result, the electric field vector is substantially perpendicular to the longitudinal direction of the electrodes when the electric field is applied, so a multi-domain structure is formed and good viewing angle characteristics can be obtained. Figure 6 The double-headed arr...

Embodiment 2

[0193] Biphenyl-4,4'-diylbis(2-methacrylate) is added to the positive liquid crystal 4-cyano-4'-pentylbiphenyl so that it is 1% by weight based on the entire liquid crystal composition ) was used as a monomer, the IPS liquid crystal cell of Example 2 was produced by the method similar to the comparative example 2. When the orientation of the liquid crystal molecules was observed with a polarizing microscope, it was found to be well uniaxially aligned. In addition, the application of an electric field above the threshold causes the liquid crystal to respond, and as a result, the liquid crystal is oriented along the meandering comb electrodes, and a good viewing angle characteristic is obtained through the multi-domain structure. In addition, the image sticking rate was measured by the same method as in Comparative Example 2. As a result, the image sticking rate was 11%, and a large improvement effect was obtained.

[0194] The reaction system of the PS treatment in Example 2 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com