Pipe joint expanded connection expanded sleeve mould

A technology for expanding sleeve die and pipe joint, which is applied in the field of die for bulging at the end, can solve the problems of low qualified product rate and low production efficiency of pipe fitting connection components, and achieves avoiding the difficulty of cleaning welding slag in the welding seam and high production efficiency. , the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

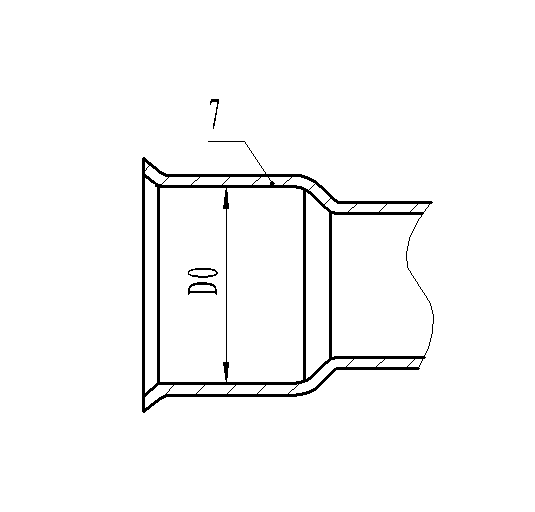

[0020] Such as figure 1 Shown is to complete the bulging pipe body end 7, and the diameter D0 of the inner hole of the pipe body end 7 is 18.2 millimeters;

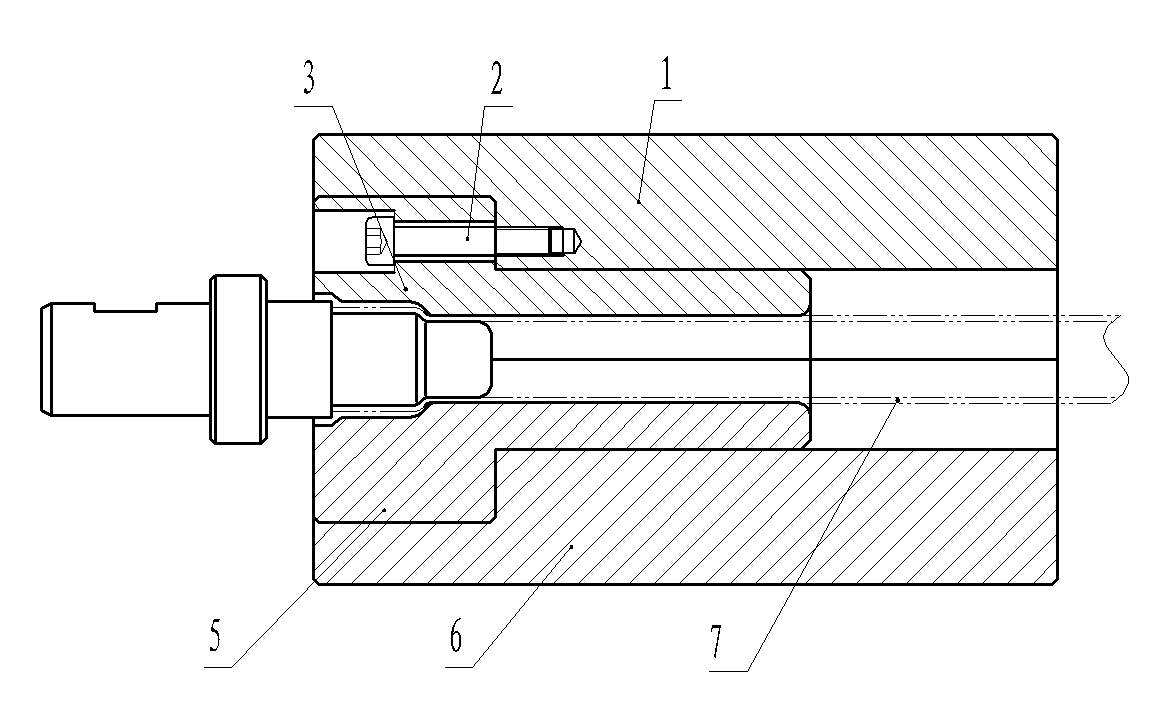

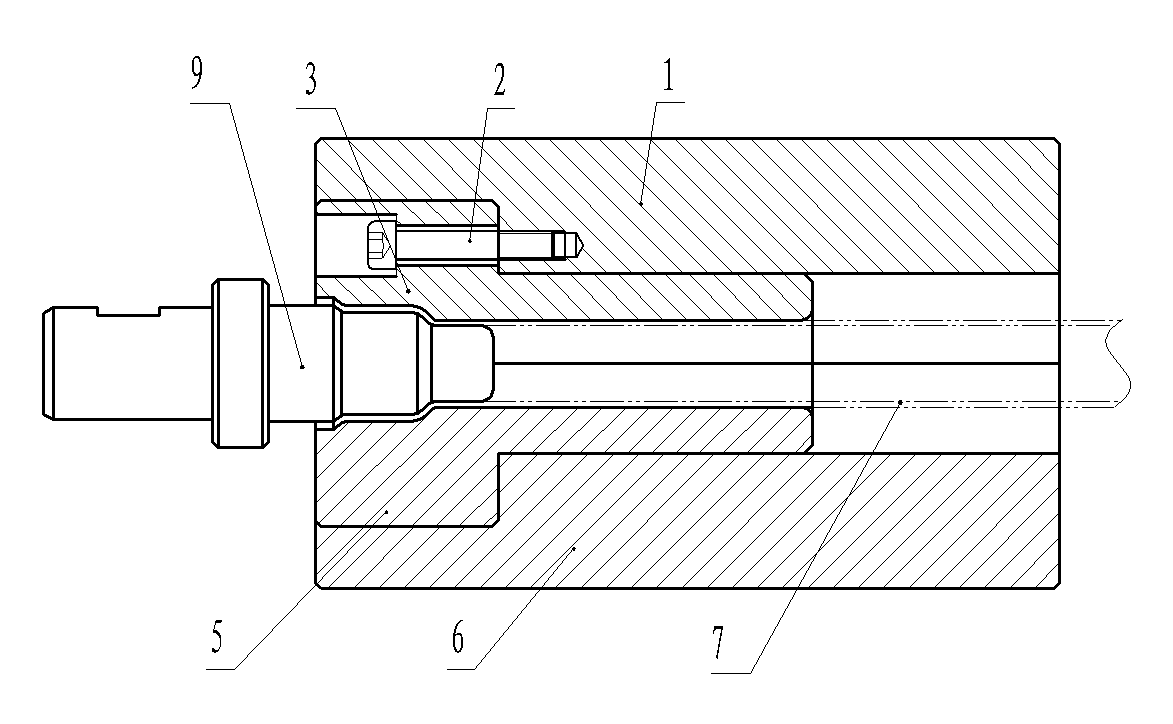

[0021] Such as figure 2 , image 3 and Figure 4 The pipe joint expansion expansion sleeve shown includes a plurality of punches with an expanding part and a forming punch 9 with a shaping part; the plurality of punches are respectively the first punch, the second punch and the third punch. Punches, the front section of the expansion tube part of these punches is a cylindrical guide post 4-1, and the middle section connected with the front section is a cylindrical bulging post 4-2 with a diameter greater than the guide post 4-1, and the middle section The connected rear section is a cylindrical positioning column 4-3 with a diameter larger than the bulging column 4-2, and a smooth transition is connected between the bulging column 4-2 and the guide column 4-1. Cone, the diameters of the bulging column 4-2 and the pos...

Embodiment 2

[0023] Such as figure 1 Shown is to complete the bulging pipe body end 7, and the diameter D0 of the inner hole of the pipe body end 7 is 18.22 millimeters;

[0024] Such as figure 2 , image 3 and Figure 4 The pipe joint expansion expansion sleeve shown includes a plurality of punches with an expanding part and a forming punch 9 with a shaping part; the plurality of punches are respectively the first punch, the second punch and the third punch. Punches, the front section of the expansion tube part of these punches is a cylindrical guide post 4-1, and the middle section connected with the front section is a cylindrical bulging post 4-2 with a diameter greater than the guide post 4-1, and the middle section The connected rear section is a cylindrical positioning column 4-3 with a diameter larger than the bulging column 4-2, and a smooth transition is connected between the bulging column 4-2 and the guide column 4-1. Cone, the diameters of the bulging column 4-2 and the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com