A car air conditioning system

An automotive air-conditioning system and compartment technology, applied in vehicle components, air handling equipment, heating/cooling equipment, etc., can solve problems such as discounting comfort in the car, increasing vehicle load, and affecting the driver's sight line, to meet comfort requirements, Avoid the impact of high and low temperature and ensure the effect of temperature and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

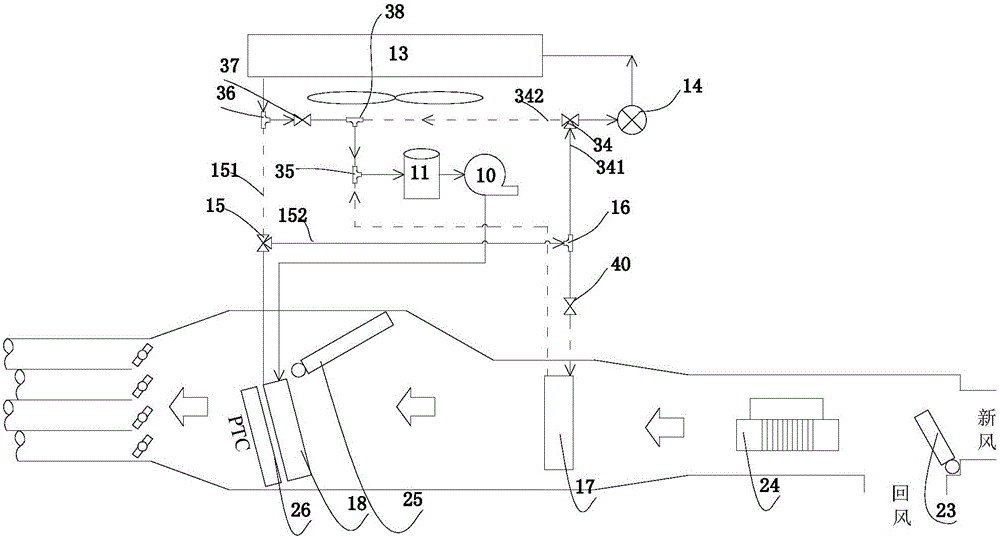

[0070] Introduce the second specific implementation mode of the present invention below, Figure 7 It is a schematic diagram of the pipeline connection of the second specific embodiment of the present invention. This embodiment is an improvement on the above first specific embodiment. A bypass channel is provided for the heat exchanger 13 outside the compartment, specifically a three-way is provided at the inlet and outlet of the heat exchanger 13 outside the compartment. Pipe fittings, the third electromagnetic three-way control valve, such as Figure 7 In the middle, a third electromagnetic three-way control valve 28 is arranged in the pipeline between the heat exchanger 13 outside the vehicle compartment and the second electromagnetic three-way control valve 15, and is arranged in the pipeline after the outlet of the heat exchanger 13 outside the vehicle compartment A three-way pipeline piece 27, an interface of the third electromagnetic three-way control valve 28 is conne...

Embodiment approach

[0072] For the other three operating modes, refer to the first specific implementation mode above, and make the relevant valves controlled by the electromagnetic control switch the relevant flow direction and change the flow mode of the refrigerant, which will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com