Gantry type ground rail cable winding mechanism

A gantry-type, wire-receiving and arranging technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of easy crimping of wire-receiving and arranging racks, excessively tight loops, and low efficiency, and achieve Solve the effect of easy crimping, balanced tension, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

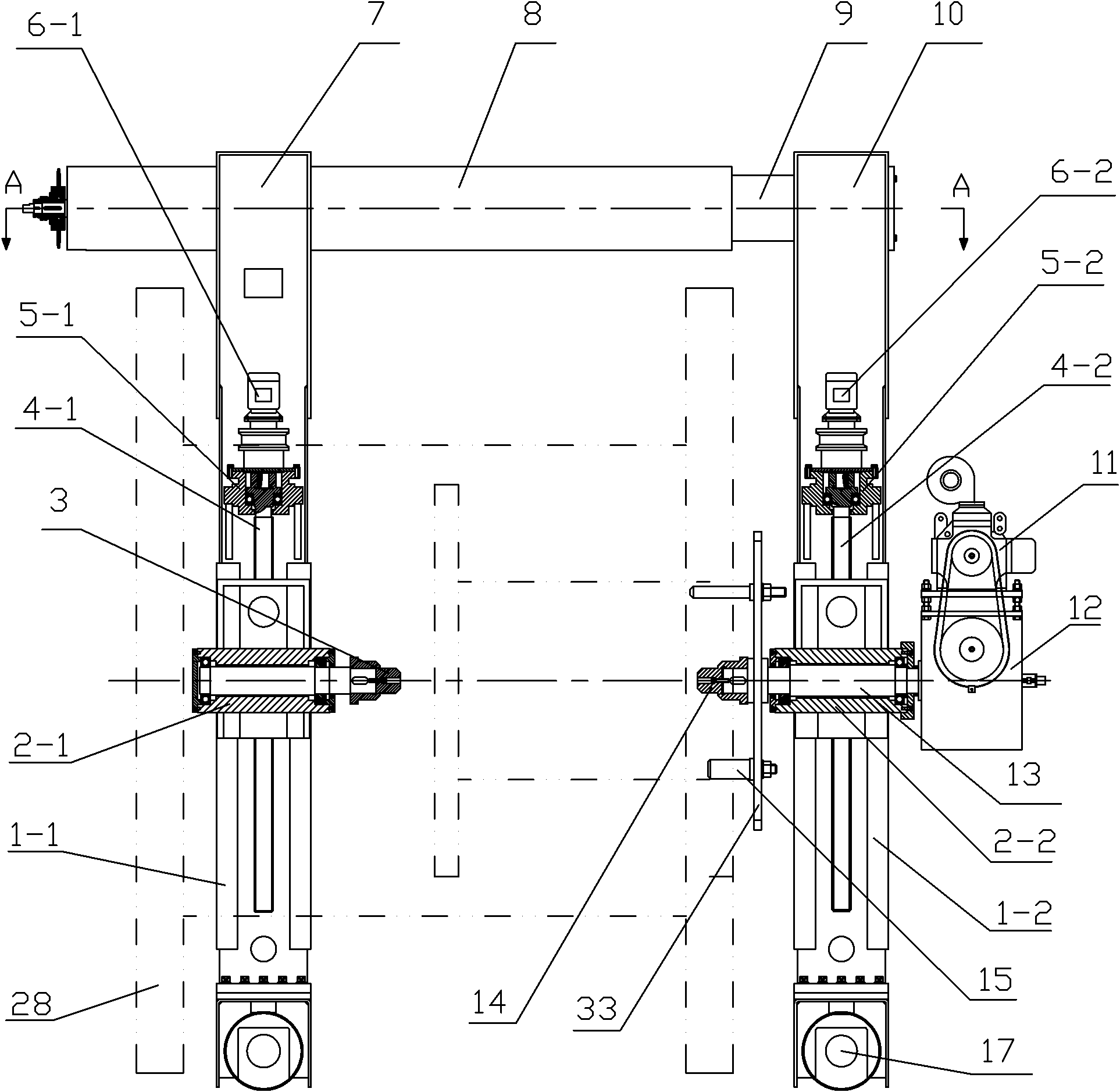

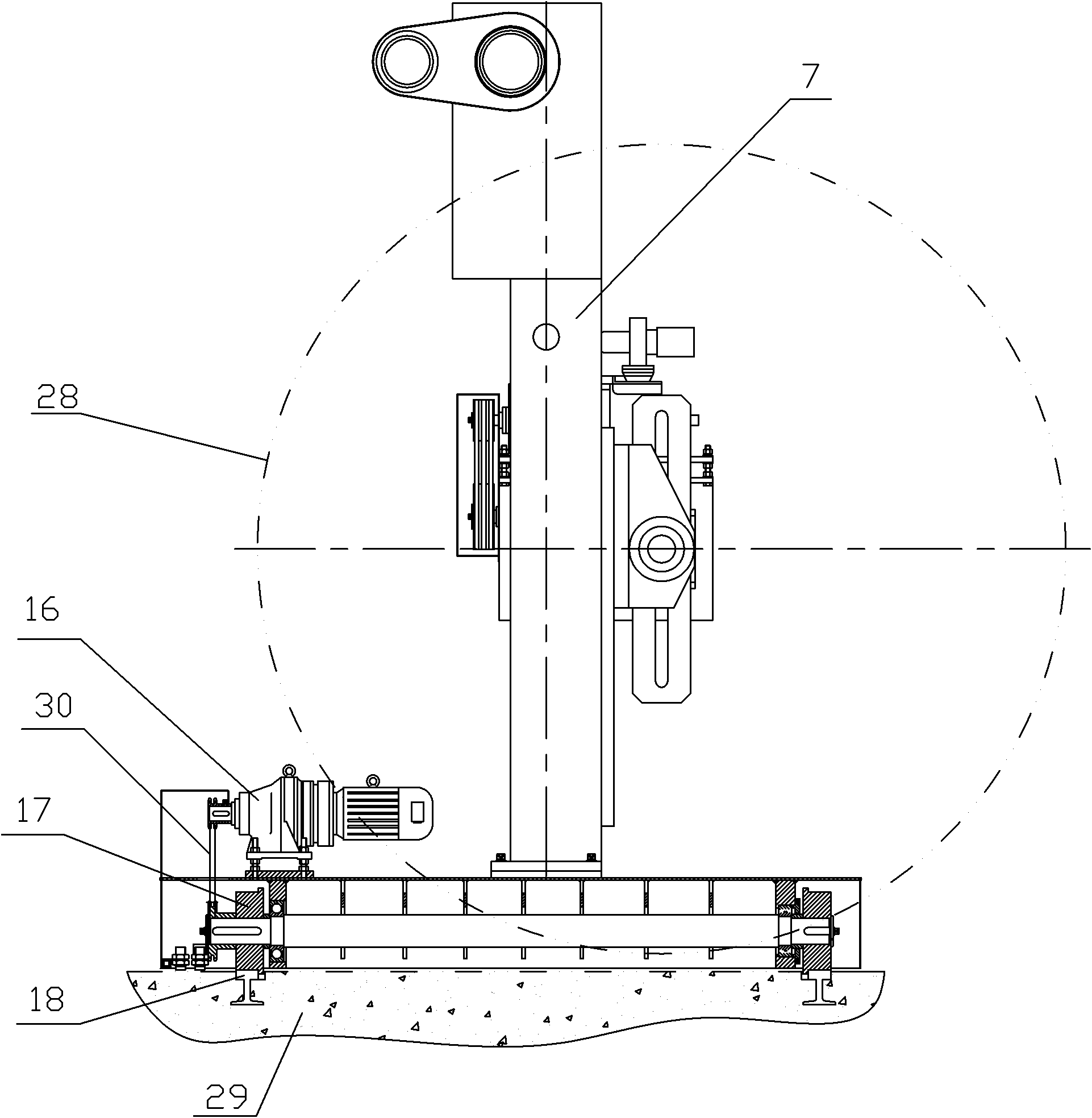

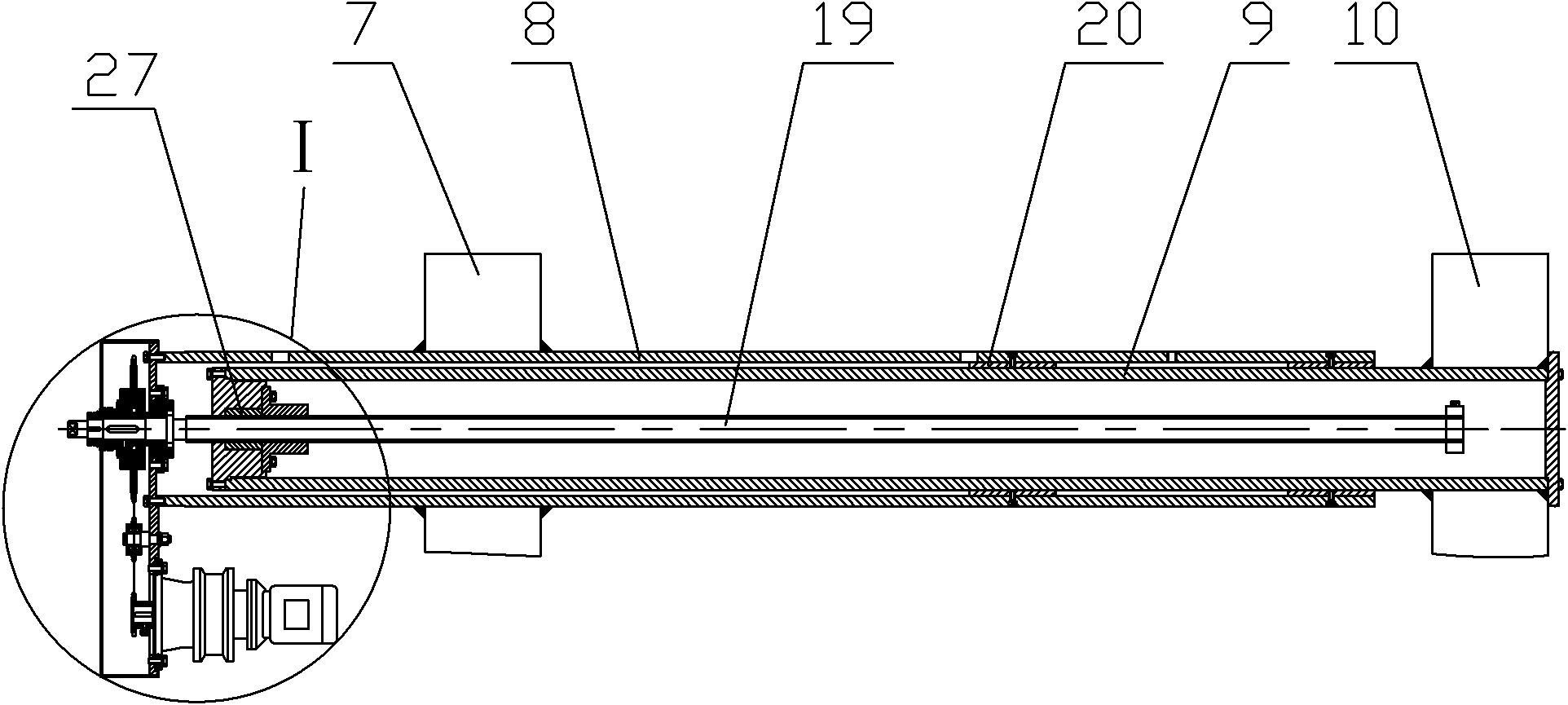

[0035] Such as Figure 1 to Figure 4 As shown, the present invention includes a crossbeam 8, an inner sleeve 9 arranged inside the crossbeam 8 and whose end is outside the crossbeam 8, a left column 7 fixedly installed at the left end of the crossbeam 8, and a right column 10 fixedly installed at the right end of the inner sleeve 9 , the inner sleeve 9 is slidingly connected with the crossbeam 8, the first drive transmission mechanism for driving the crossbeam 8 to move left and right is installed on the crossbeam 8, the lower end of the left column 7 is connected to the first guide rail 1-1, and the first The movable center 3 is installed on the guide rail 1-1 through the movable center seat 2-1, and the movable center seat 2-1 is slidingly connected with the first guide rail 1-1; the lower end of the right column 10 is connected with the second guide rail 2-2, A fixed top 14 is installed on the second guide rail 1-2 through a fixed top seat 2-2, and the fixed top seat 2-2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com