Preparation method of collagen-based sponge wound dressing with self-anti-inflammatory function

A collagen-based sponge and wound dressing technology, applied in the application field of biomedical materials, can solve the problems of loss, unable to maintain synergistic anti-inflammatory effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0011] Example one (using liquid cross-linking method)

[0012] First, add 10g of polyvinylpyrrolidone to 100mL of potassium hydroxide solution with a concentration of 50mg / mL, then react in a pressure-resistant sealed bottle at a temperature of 130°C for 12 hours, remove the solvent, reconstitute with dichloromethane, and filter out the insoluble After the solvent was evaporated to dryness, the ring-opened polyvinylpyrrolidone was obtained, and the ring-opening rate was 4%. Mix 100mg of collagen with 100mg of ring-opened polyvinylpyrrolidone and dissolve to a concentration of 10mg / mL, then add 1mmol of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 0.5 1 mmol of N-hydroxysuccinimide was activated and cross-linked in the mold for 16 hours at a cross-linking temperature of 25°C. Afterwards, the cross-linked product was soaked and rinsed with deionized water to remove excess activator and freeze-dried to obtain a sponge product , and the samples were stored in ...

example 2

[0013] Example two (using solid state cross-linking method)

[0014] First, add 2.5 g of polyvinylpyrrolidone to 100 mL of potassium hydroxide solution with a concentration of 25 mg / mL, then react in a pressure-resistant sealed bottle at a temperature of 140 °C for 24 hours, remove the solvent, redissolve with dichloromethane, and filter out After the insoluble matter was evaporated to dryness, the ring-opened polyvinylpyrrolidone was obtained, and the ring-opening rate was 8%. Mix 100mg collagen with 50mg ring-opened polyvinylpyrrolidone and dissolve it to a concentration of 7.5mg / mL, freeze-dry it in a mold, and then soak the freeze-dried product in a solution containing 1-(3-dimethylaminopropyl)-3 - the concentration of ethylcarbodiimide hydrochloride is 50mmol / L, the concentration of N-hydroxysuccinimide is 25mmol / L in 90% acetone solution to activate cross-linking, the cross-linking time is 24 hours, the cross-linking temperature temperature at 20°C, and then soak and ri...

example 3

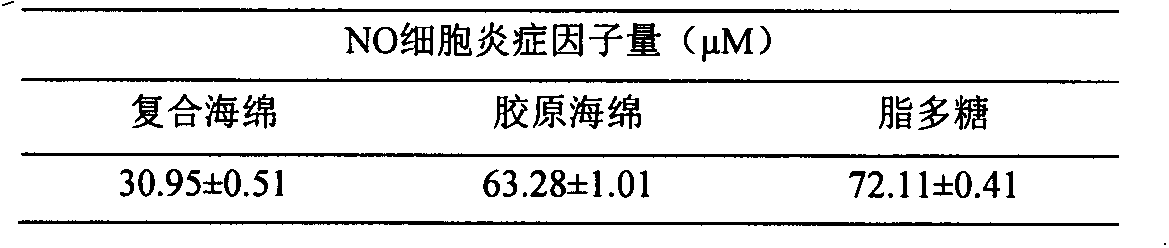

[0016] The physical and chemical properties of the prepared composite sponge dressing were evaluated, and the pure collagen sponge was used as the blank control.

[0017] 1. Experimental method

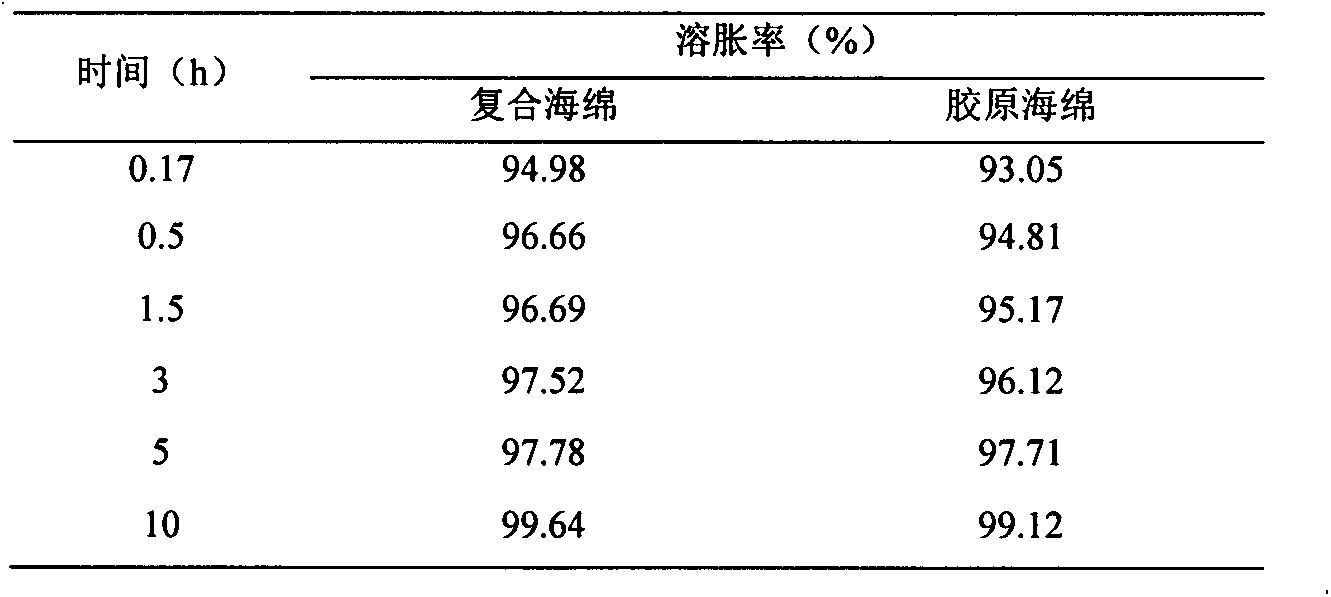

[0018] (1) Determination of swelling rate:

[0019] Weigh 10 mg of completely dry sponge sample and soak it in PBS buffer (pH7.4), at the specified time point, take out the sample, carefully wipe off the surface solution, and then weigh (W t ), the weight after fully swelling is W s . The swelling rate of the sponge (Swelling ratio, SR) is calculated according to the following formula:

[0020] SR(%)=(W t -10)×100 / W s

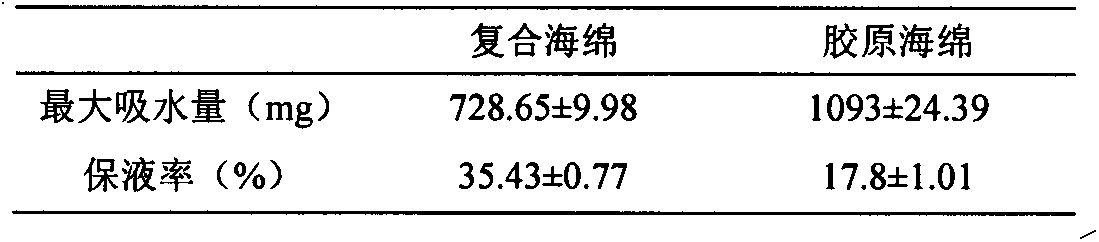

[0021] (2) Determination of maximum water absorption and water retention rate:

[0022] First soak 10 mg of the fully dried sponge sample in PBS buffer (pH7.4) for 24 hours to swell completely, and the weight is W s , the maximum water absorption is W s -10, then put it into a centrifuge tube with a filter, centrifuge at 500rpm for 3 minutes, then take it out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com