Device and method of temperature gradient control in growth process of crystal material

A technology for growing crystals with temperature gradients, applied in crystal growth, post-processing devices, chemical instruments and methods, etc., can solve problems such as uneven heating, deviation of placement angle, and quality decline, and achieve reduced use costs and uniform heating temperature field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

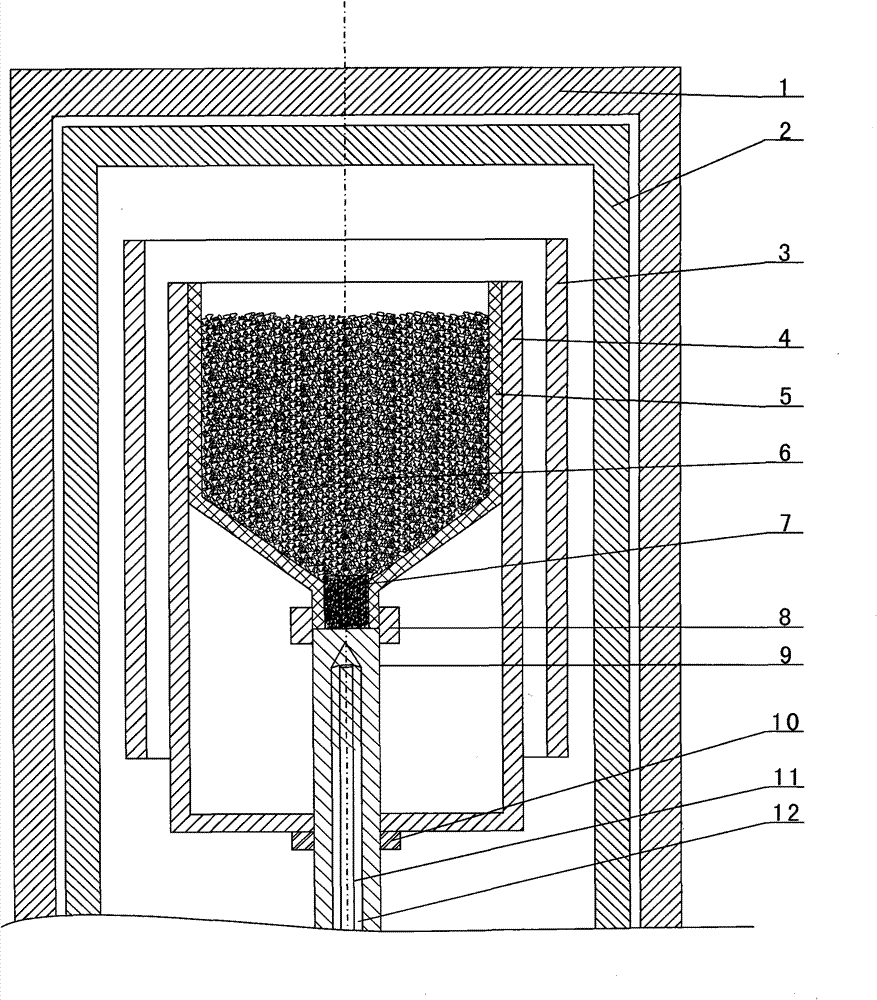

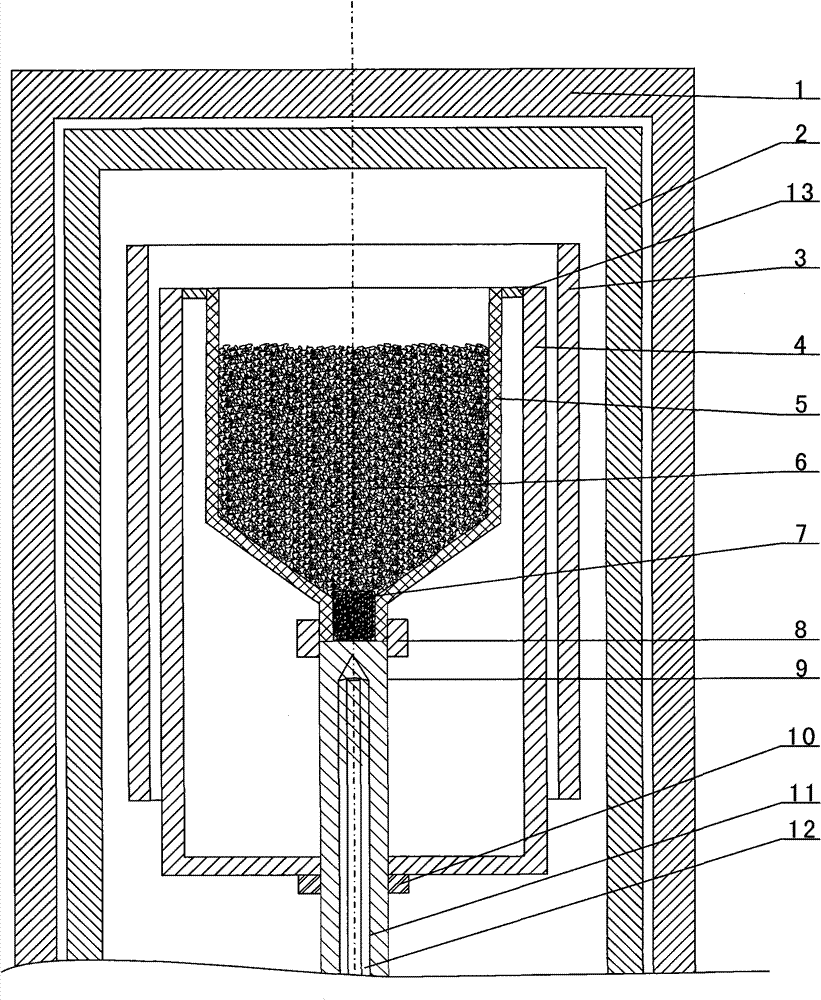

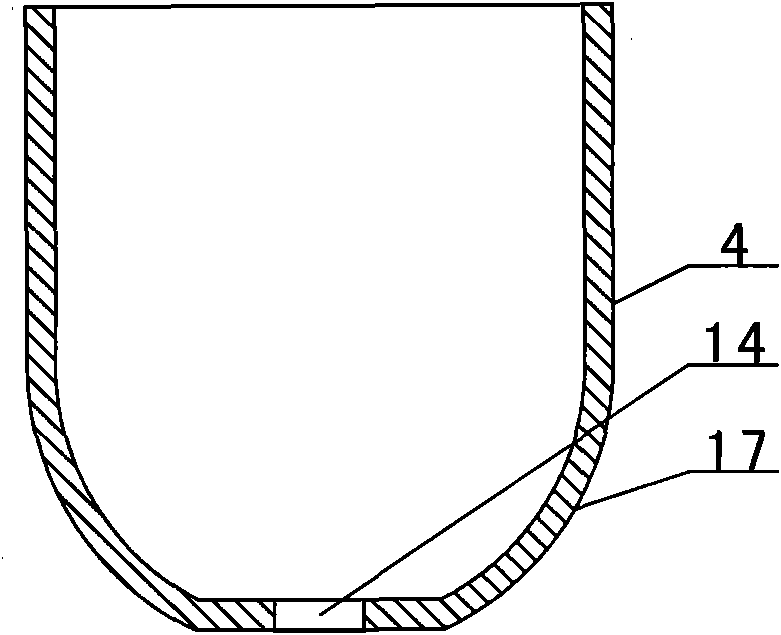

[0080] combined with figure 1 , 2 The temperature gradient control device when a kind of growth crystal material is described in, comprises furnace chamber 1, heating element 3, sleeve 4, crucible 5 and cooling medium cooling mechanism, is provided with crucible 5 in furnace chamber 1, and the crucible 5 The lower part is inside the sleeve 4, and the upper part of the sleeve 4 is provided with an upwardly extending part, and the inner side of the upwardly extending part of the sleeve 4 wraps the outer upper part of the crucible 5, combined with the attached figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com