Tube-sinking cast-in-site pile combined feeding hopper pile and construction method

A technology of sinking cast-in-situ piles and combined feeding, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increasing filling coefficient, wasting materials, and increasing the force of concrete lateral extrusion, and achieves reduction Small filling coefficient, guaranteed pile quality, and reduced drop height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

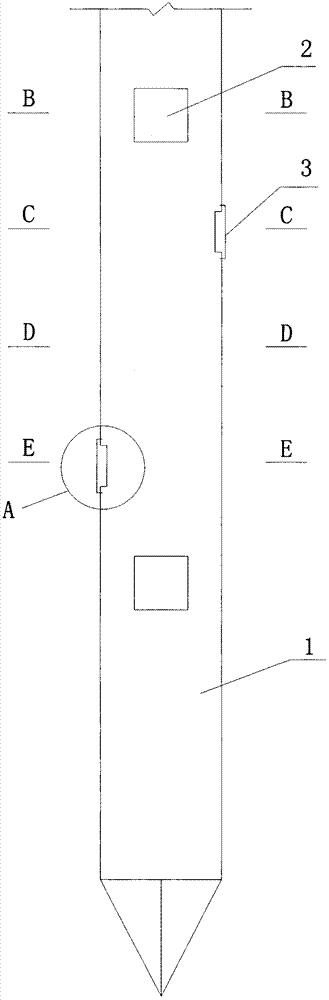

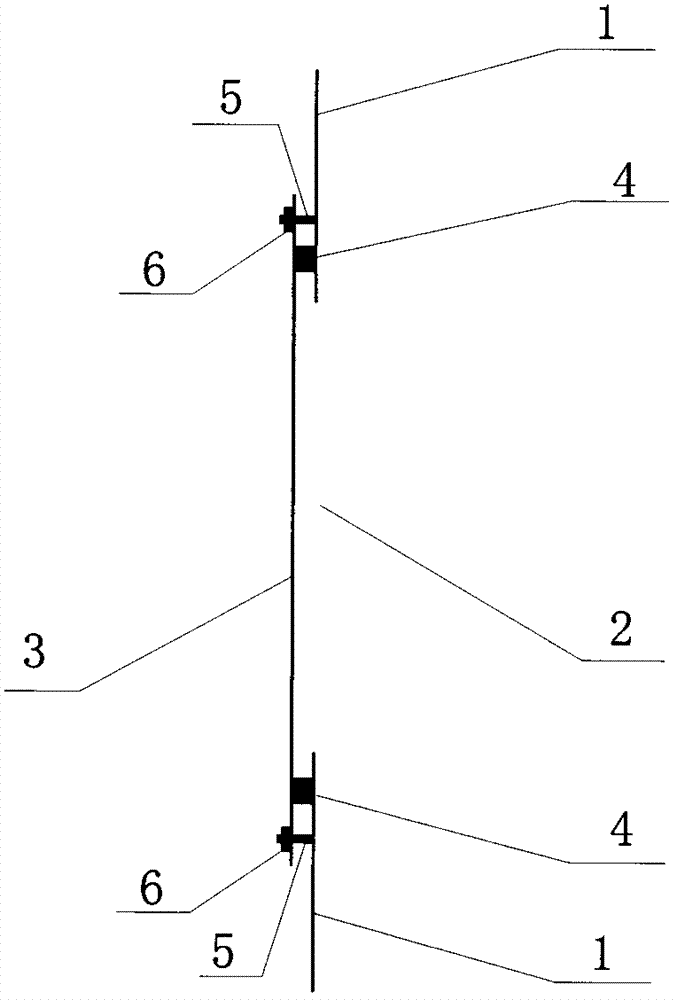

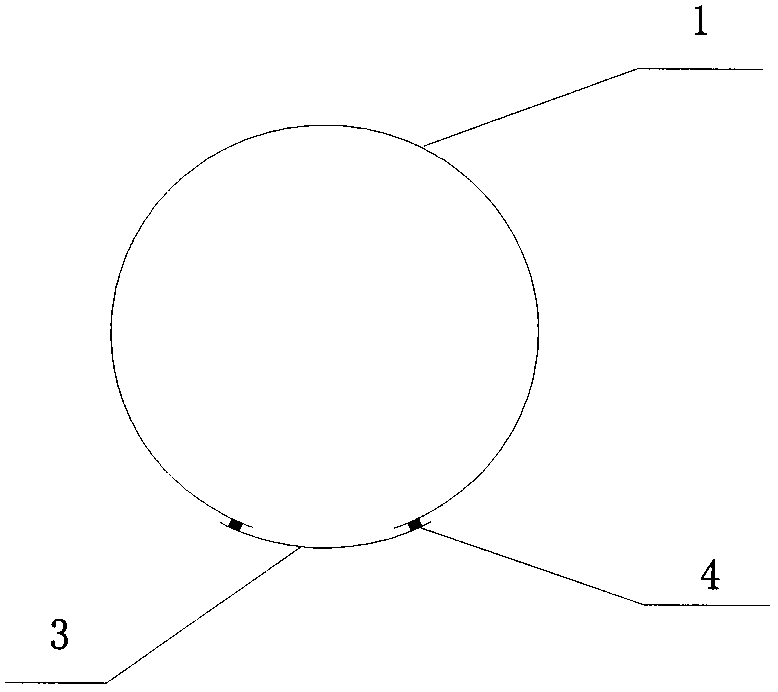

[0045] Such as Figure 1 to Figure 7 Shown:

[0046] Immersed tube cast-in-situ pile combined feed hopper pile formwork, set multiple square openings on the side of pile formwork 1 as the feed inlet 2, and weld more than two screws above and below the feed inlet 2, or on the left and right sides respectively. Screw male 5, prepare a curved plate whose width and height are greater than the feed port 2 as the cover plate 1, the radius of the cover plate 1 of the arc plate is equal to the radius of the pile formwork 1, so as to ensure that the arc shape on the outside of the cover plate 1 is consistent with the The outer arc of the pile formwork 2 is the same, so as to ensure the quality of the pile, and a hole is reserved on the cover plate 3 corresponding to the position of the screw male 5; there are sealing strips 4 around the inside of the cover plate 3, so as to make it compact and watertight; Cover the cover plate 3 on the feed port 2, the screw 5 passes through the reser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com