Lens for ultraviolet light-emitting diode (LED) collimation

A lens and ultraviolet technology, applied in semiconductor lighting technology and application fields, can solve problems such as unsatisfactory collimation effect, and achieve the effects of simple structure, prolonged service life and good collimation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 adopts the LED collimating lens of integrated design

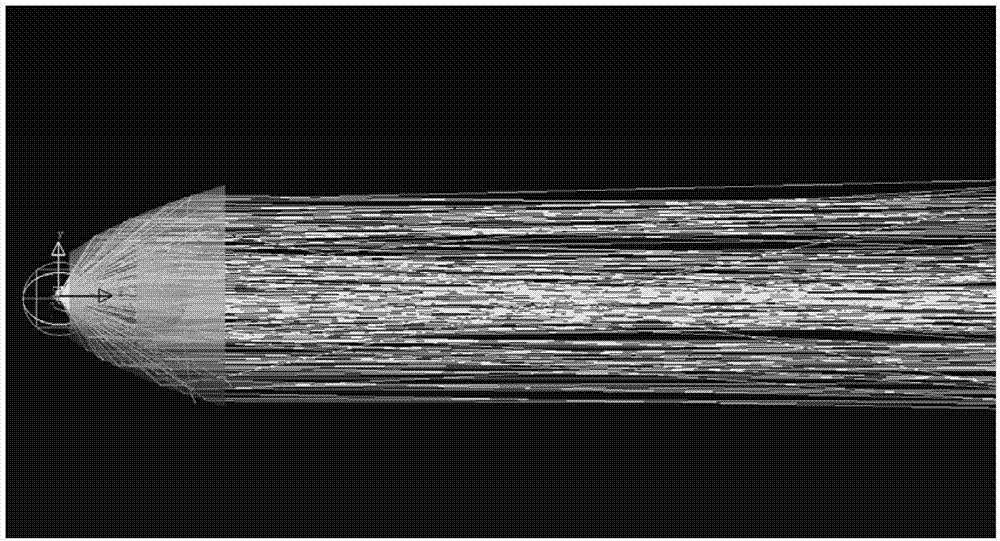

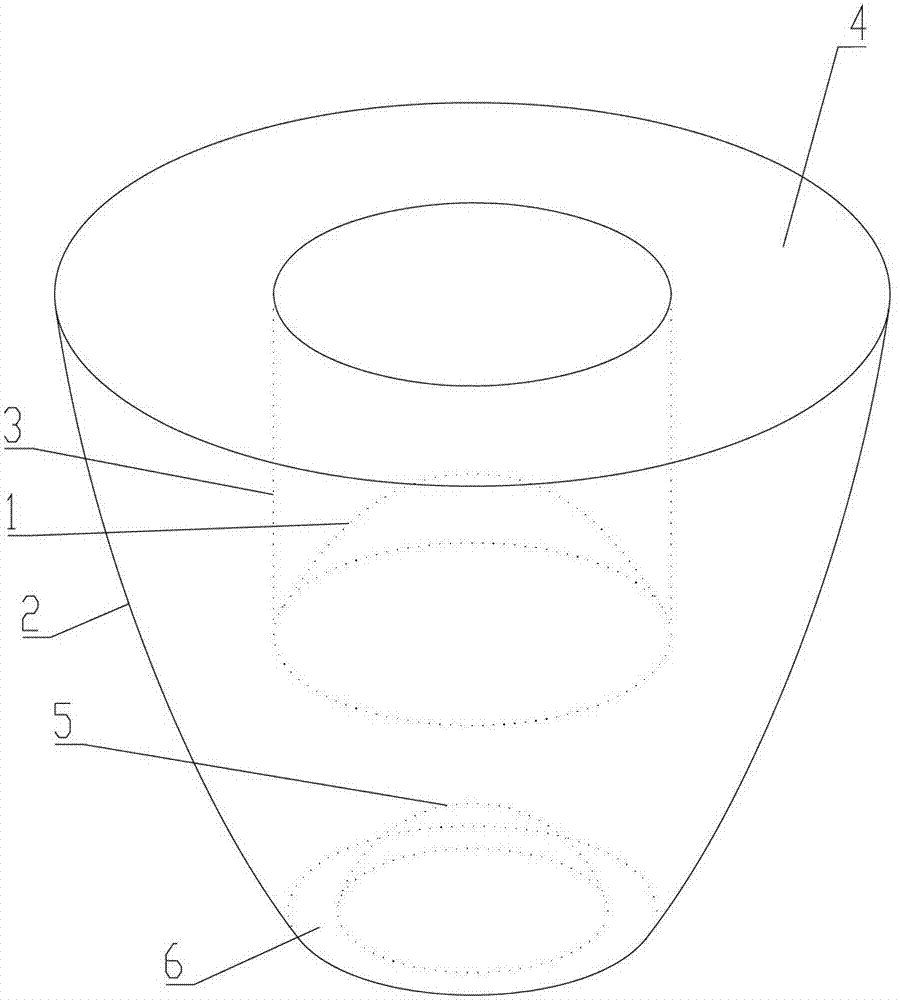

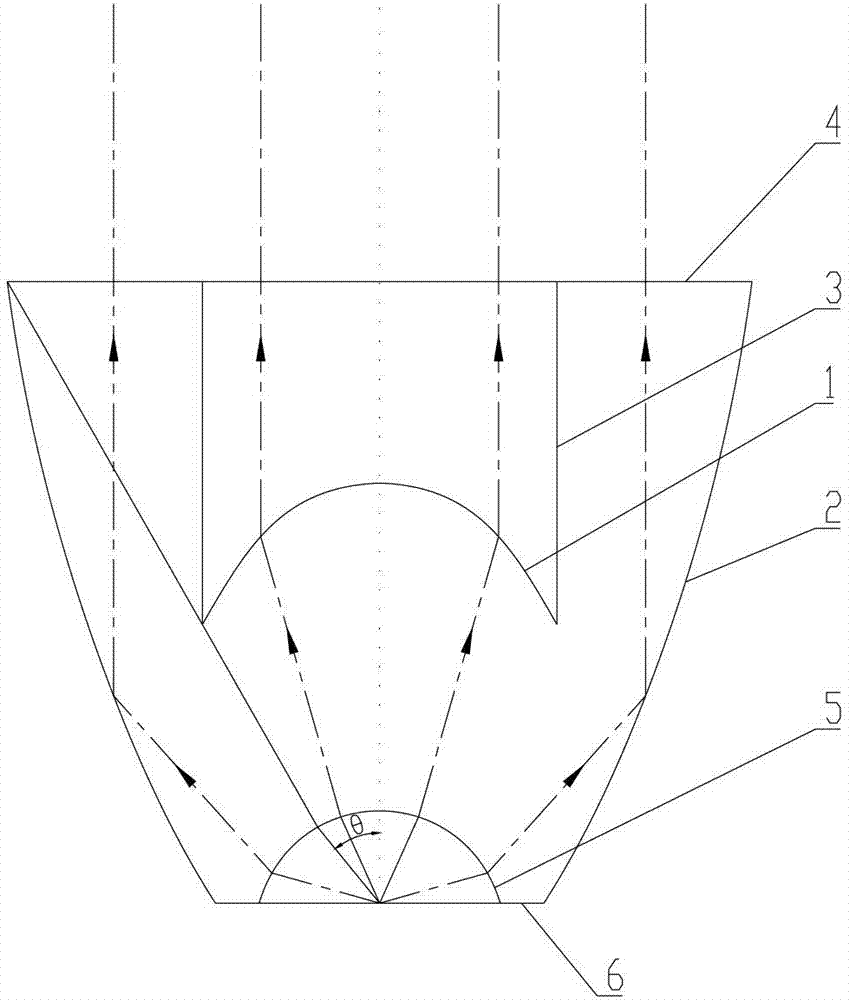

[0034] The lens shown in this embodiment includes a first free-form surface 1 and a total reflection free-form surface 2, the first free-form surface 1 and the total-reflection free-form surface 2 are rotators with the optical axis as the axis, and the total-reflection free-form surface 2 The opening of the opening gradually increases along the exiting direction of the optical axis; the first free-form surface 1 is arranged inside the total reflection free-form surface 2, and the first free-form surface 1 is convex along the exiting direction of the optical axis. The first free-form surface 1 is used to refract the light near the optical axis, so that the light can be emitted parallel to the optical axis; the total reflection free-form surface 2 is used to reflect the light far away from the optical axis, so that the light can emitted parallel to the optical axis.

[0035]The lens in this embodiment al...

Embodiment 2

[0044] Embodiment 2 LED collimating lens with split design

[0045] The lens described in the second embodiment is designed and manufactured separately from optical quartz material and reflective material. like Figure 5 As shown, wherein, the reflective material is used to make the total reflection free-form surface 2; the optical quartz material is used to make the first free-form surface 1 and the second free-form surface 5. In the split design, the lens omits the connecting surface and the outgoing surface, so that the structure of the lens is much simpler than that of the first embodiment, and its manufacture is not as complicated as the lens in the first embodiment. In addition, as an alternative to the second embodiment, the lens portion with the first free-form surface 1 and the second free-form surface 5 and the LED light source 7 in the second embodiment may also be packaged integrally.

[0046] As a further improvement of Embodiments 1 and 2, the first free-form s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com