Vapor recycling water heater

A water heater and heat energy recovery technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve problems such as heat waste, and achieve the effects of low cost, simple structure and less improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

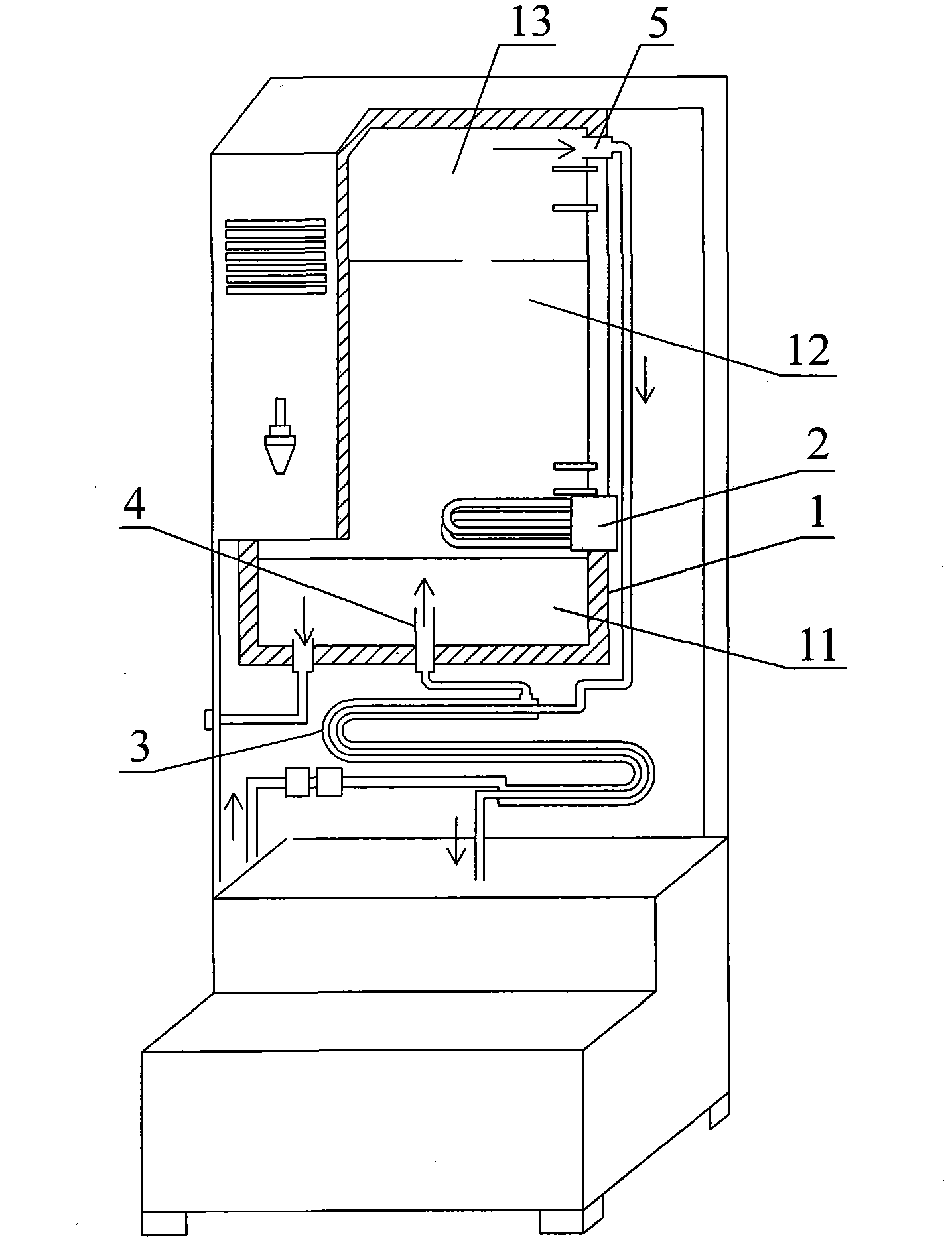

[0012] Examples, see figure 1 Shown: steam recovery water heater, including hot water chamber 1. A heater 2 is provided in the middle of the hot water chamber 1 . The bottom of the wall of the hot water chamber 1 has a water inlet 4, and the top of the wall of the hot water chamber 1 has a steam port 5. In this way, cold water with a relatively low temperature enters the hot water chamber 1 through the water inlet 4, and is heated by the heater 2 to form hot water, and part of the hot water continues to increase in temperature to form hot steam. That is, the inside of the hot water chamber 1 forms a cool water zone 11 with a relatively low temperature, a hot water zone 12 with a temperature of 100° C., and a steam zone 13 mainly composed of steam from bottom to top. Obviously, the hot water outlet of the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com