Circuit and method for measuring internal resistance of single battery in power battery box

A battery cell and measuring circuit technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of inability to measure battery, lack of single battery resistance measurement function, increase time and cost, and achieve low power consumption. , The effect of simple measurement and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

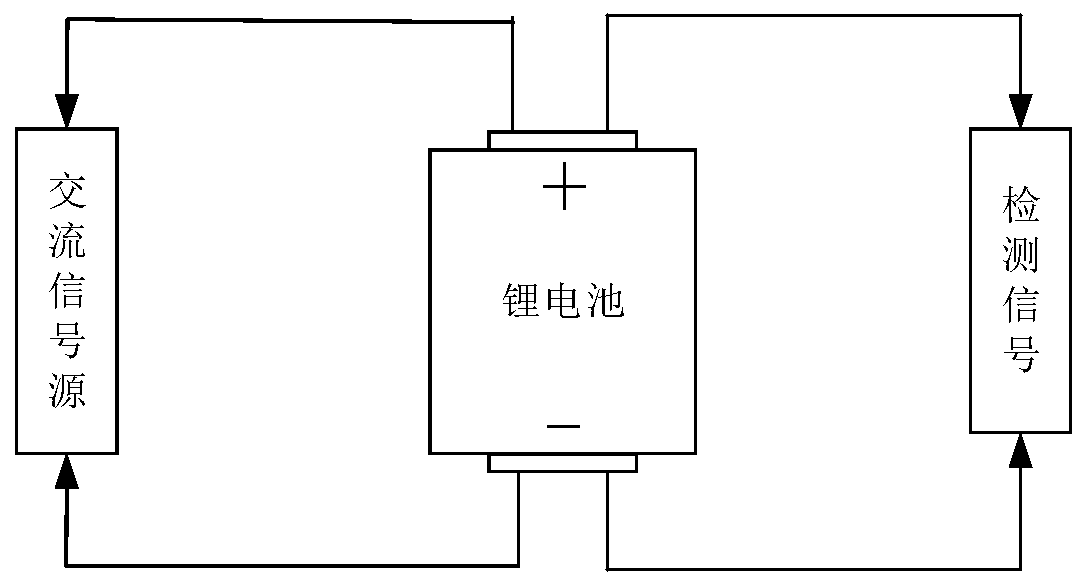

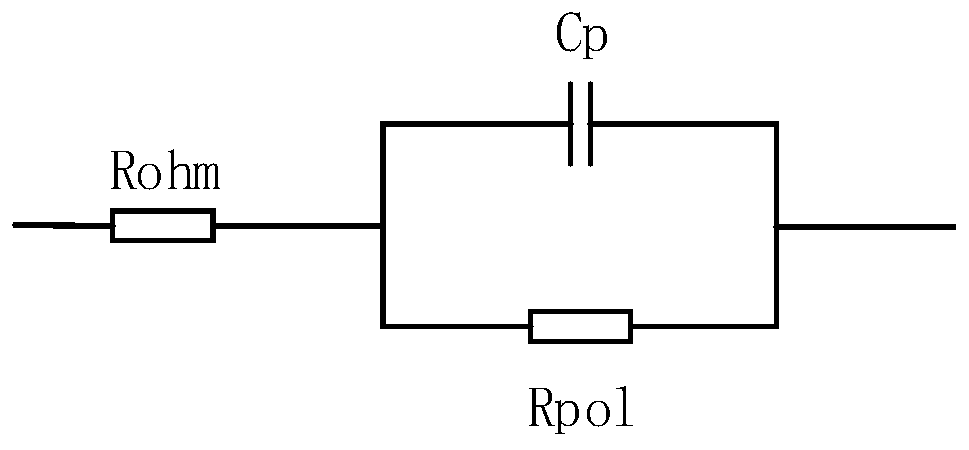

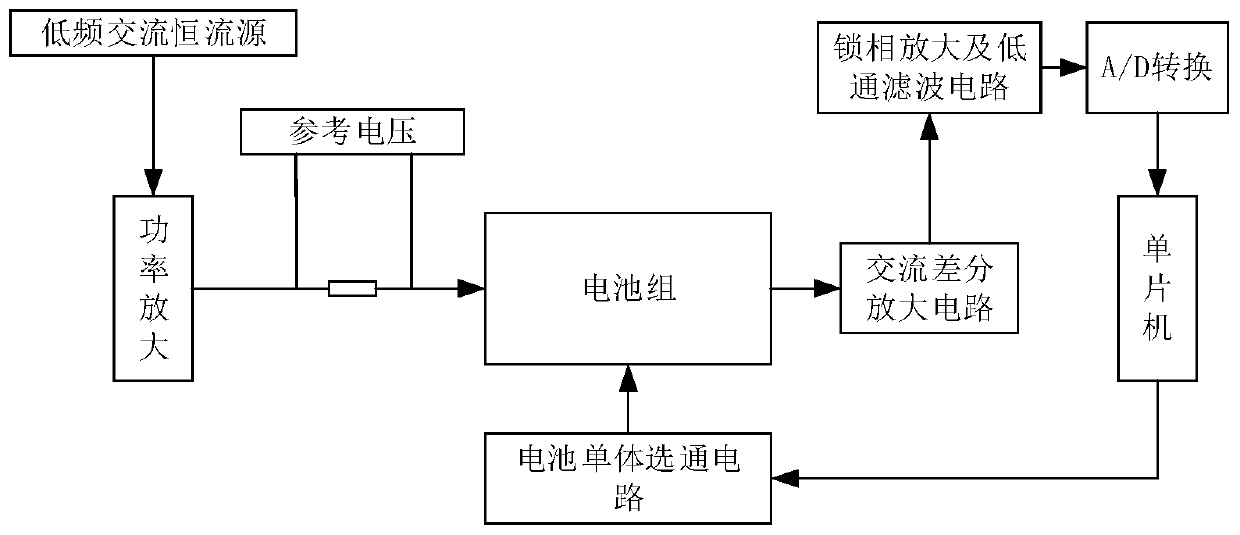

[0029] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0030] There are three main methods of measuring battery internal resistance: open circuit voltage method, DC discharge method and AC impedance method:

[0031] 1. The open-circuit voltage method is an internal resistance measurement method that estimates the internal resistance of the battery by measuring the open-circuit terminal voltage of the battery. However, because the battery terminal voltage changes during the charging and discharging process, the internal resistance cannot be accurately measured.

[0032] 2. The DC discharge method is to pass a large DC current through the battery in a short period of time, measure the voltage at both ends of the battery, and calculate the current internal resistance of the battery according to Ohm's law, but it can only be measured statically, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com