Hub motor multi-angle rotating vacuum encapsulation device

A hub motor, multi-angle technology, applied to the surface coating liquid device, coating and other directions, can solve the problems affecting the quality of the hub motor, many bubbles, insufficient filling, etc., to achieve strong practical promotion value, small range, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

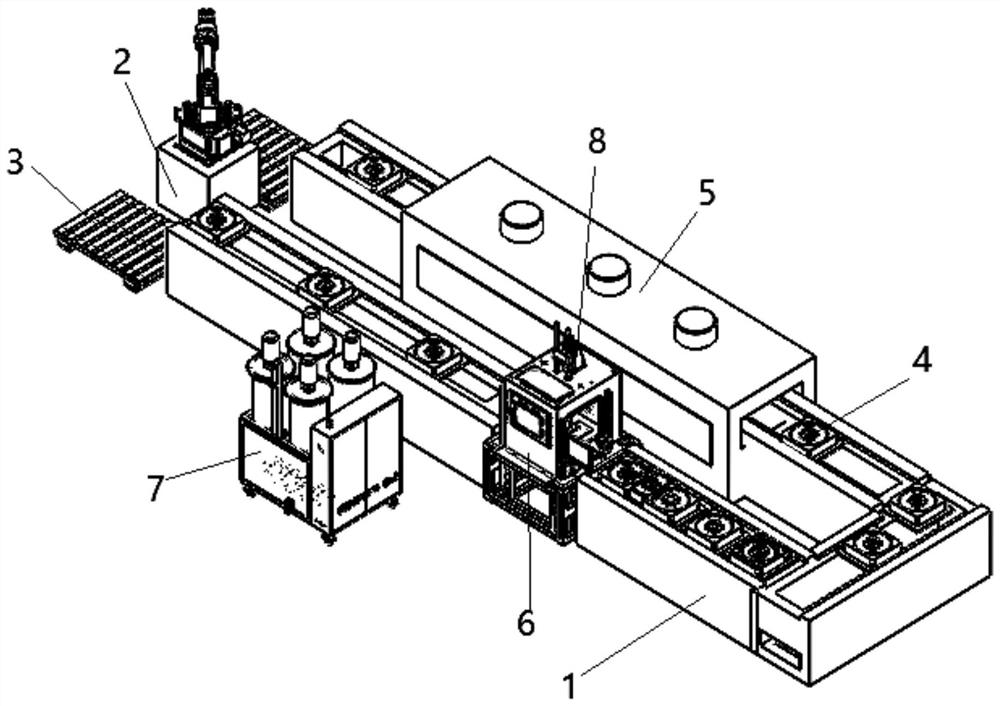

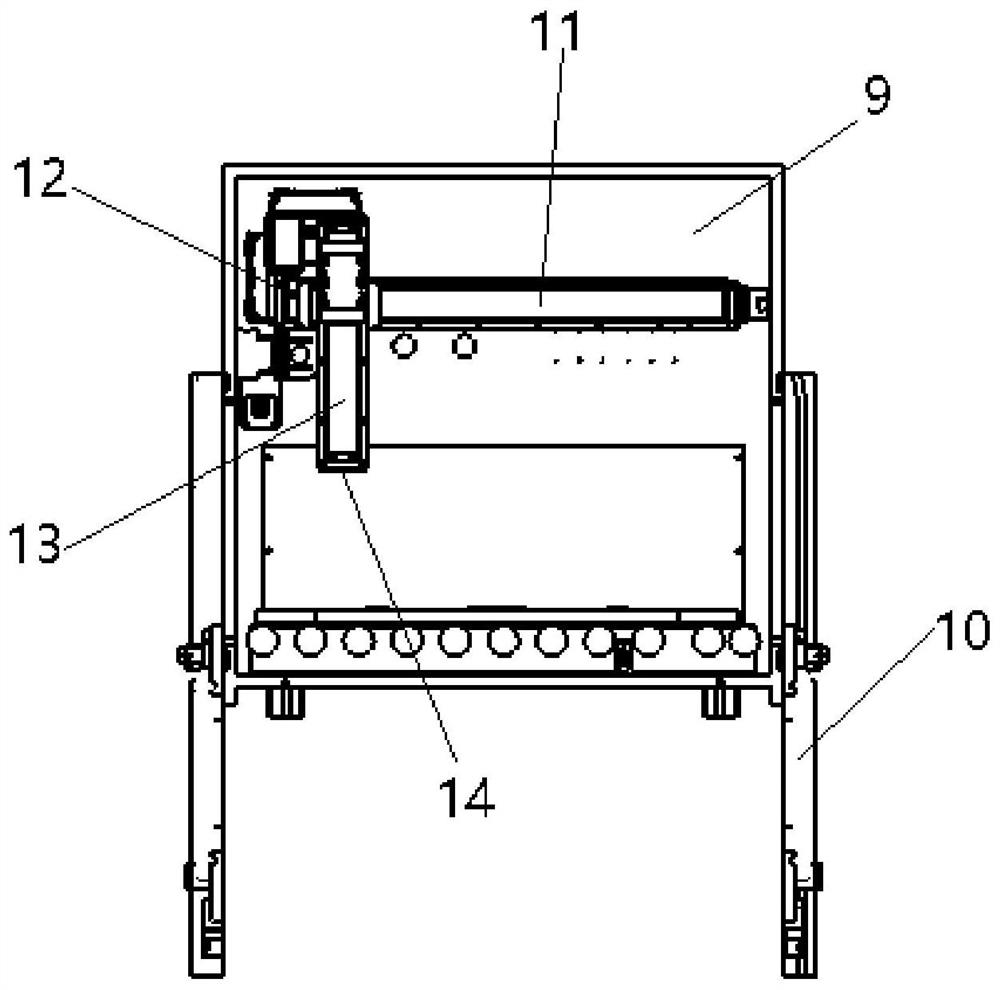

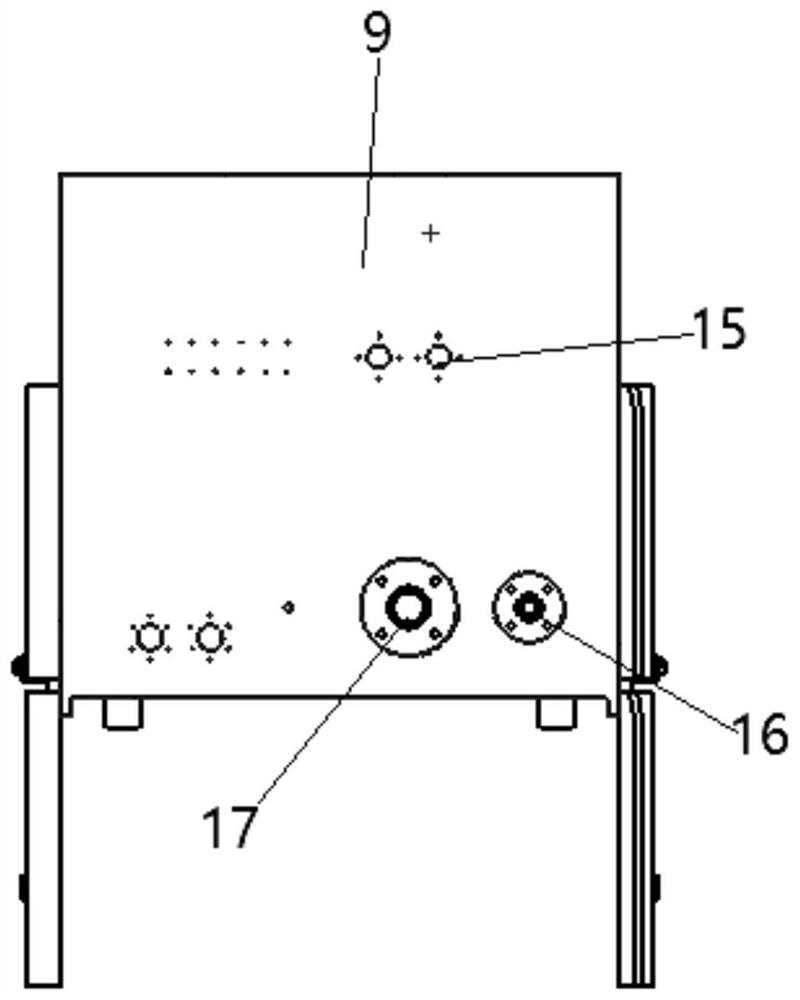

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 shown;

[0024] The inventive point of the present application is that a vacuum glue filling device 6 is installed on the assembly line, the vacuum glue filling device is close to the discharge end of the assembly line, the vacuum glue filling device is equipped with a glue filling machine 7 and a vacuum pump 8, and the glue filling machine Located on one side of the assembly line, the vacuum pump is installed on the vacuum glue filling device;

[0025] The invention of the present application is also that the vacuum potting device includes a vacuum potting chamber 9, the vacuum potting chamber is installed on an assembly line, and the assembly line runs through the vacuum potting chamber along the direction from the right side surface to the left side surface of the vacuum potting chamber, An automatic lifting door 10 is installed on the left surface and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com