Supporting-catch wheel with external refueling device

A technology of refueling device and blocking wheel, which is applied to lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of inconvenient bearing refueling, affecting the normal operation of carbon rotary kiln, bearing damage, etc., to reduce abnormal damage, The effect of prolonging life and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

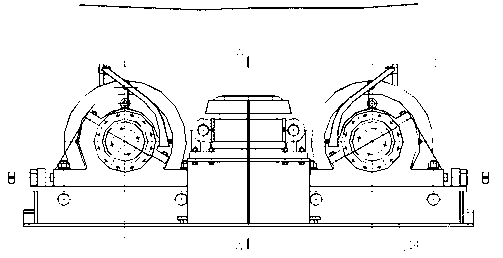

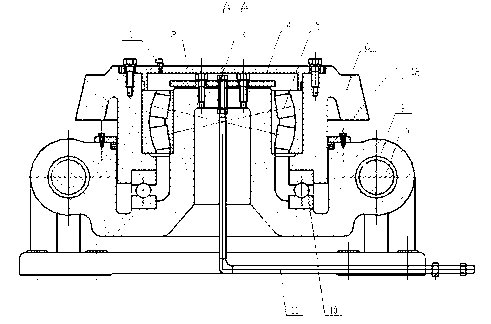

[0011] Embodiments of the present invention: as attached figure 1 and figure 2 As shown, the stop wheel consists of an oil cup 1, an outer stuffy cover 2, an upper nut 3, an inner cover 4, an upper bearing 5, a stop wheel upper seat 6, a ring cover 7, a lower seat 8, a connecting shaft 9, and a lower bearing 10, leading out Oil pipe 11, gasket 12 etc. are formed.

[0012] The blocking wheel part is set in the lower seat 8 by the upper seat 6 of the blocking wheel and the lower bearing 10 and the upper bearing 5 are installed therein, and then the outer rings of the upper seat 6 and the lower seat 8 of the blocking wheel are connected with a gasket 12 and a ring cover 7, Prevent lubricating oil from leaking. The upper end of lower seat 8 is connected with inner cover 4 to fix upper bearing 5, and the upper end of retaining wheel upper seat 6 is connected with outer stuffy cover 2, and upper bearing 5 is also fixed simultaneously. Both side parts of lower base 8 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com