Plastic optical fiber with W-shaped refractive index distribution

A technology of refractive index distribution and plastic optical fiber, which is applied in the direction of multi-layer core/clad optical fiber, clad optical fiber, optical waveguide light guide, etc., can solve the problems of long monitoring distance, low false alarm rate and high false alarm rate, and achieve The effect of convenient processing and manufacturing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

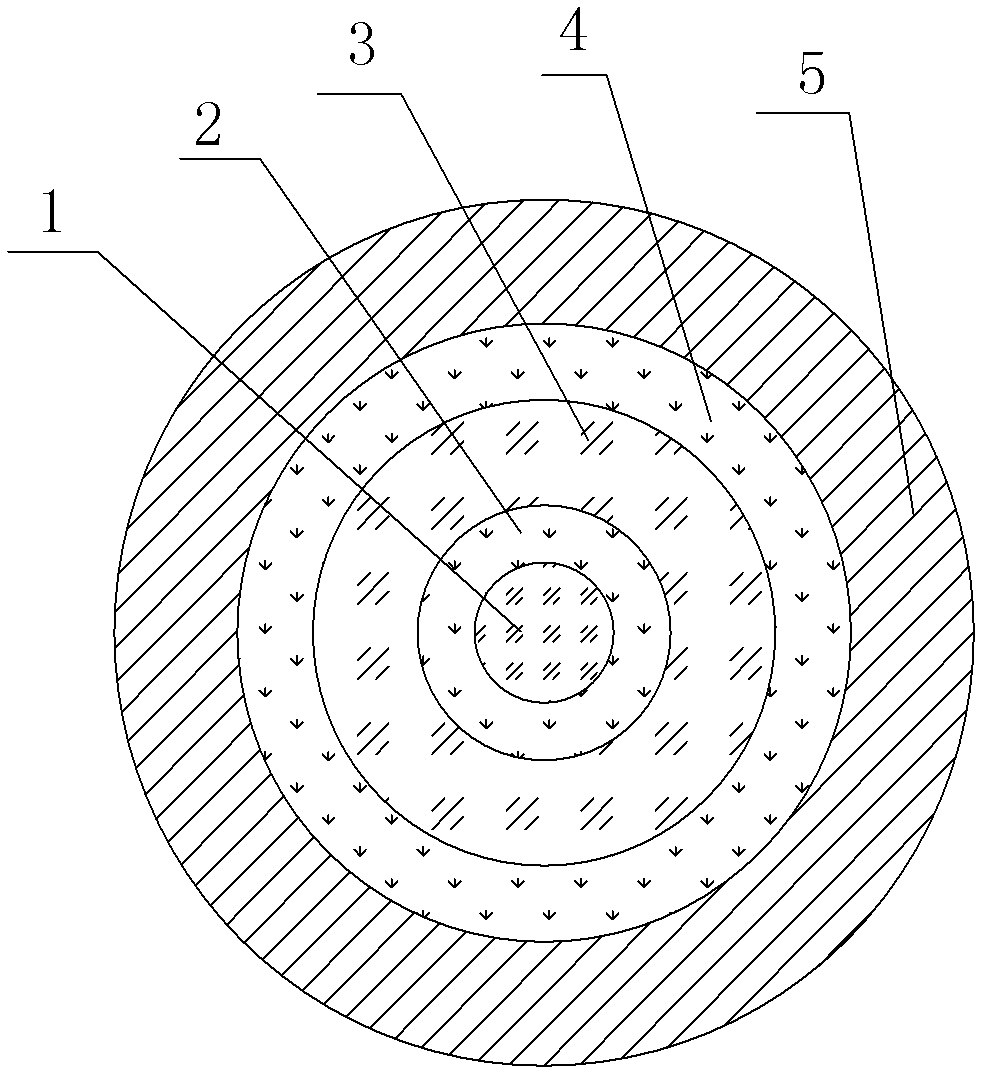

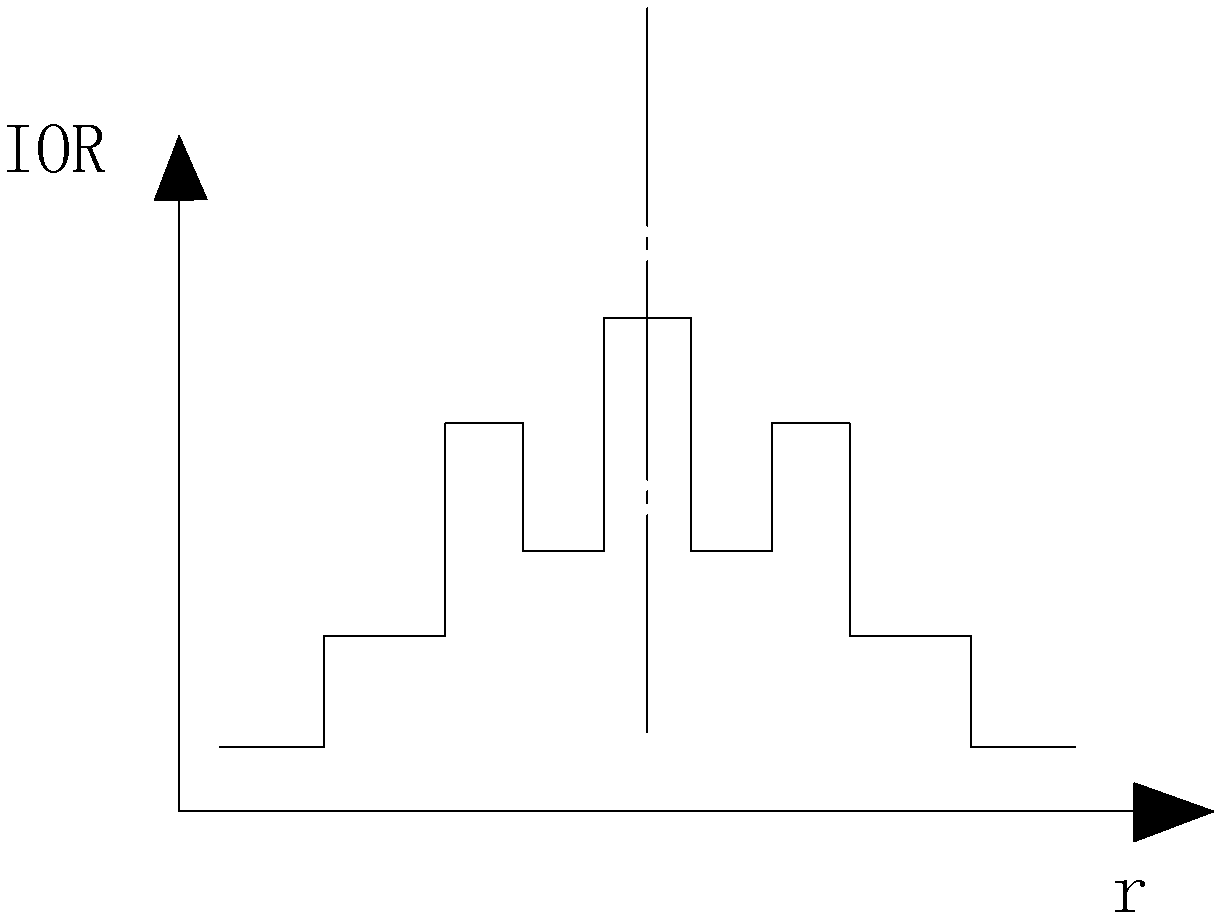

[0024] Such as figure 1 , figure 2 A plastic optical fiber with a W-shaped refractive index distribution is shown, which is radially distributed from the center to the edge, and sequentially includes a core 1, a cladding 2, a cladding 2 and a cladding 4. The core 1 The refractive index of cladding layer 1 is greater than the refractive index of cladding layer 1, the refractive index of cladding layer 2 3 is greater than the refractive index of cladding layer 2 and cladding layer 3 4, and the outer side of cladding layer 3 4 is a protective layer 5; and the cladding layer Two 3 and cladding three 4 are made of polymer materials.

[0025] When optical signals are injected into the end face of a plastic optical fiber with a W-shaped refractive index distribution, there are optical signals in the core 1, cladding 2, cladding 2 3 and cladding 3 4, but after a short transmission distance, the cladding 1 Part of the optical signal in 2 is coupled into the core 1, part of it is cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com