A kind of backlight driving circuit and its driving method and liquid crystal device

A technology of backlight drive circuit and constant current drive chip, which is applied in the direction of electrical components, instruments, static indicators, etc., which can solve the impact of the components of the backlight drive circuit, the power of the backlight drive circuit is too high, and the working life of the backlight drive circuit is reduced And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

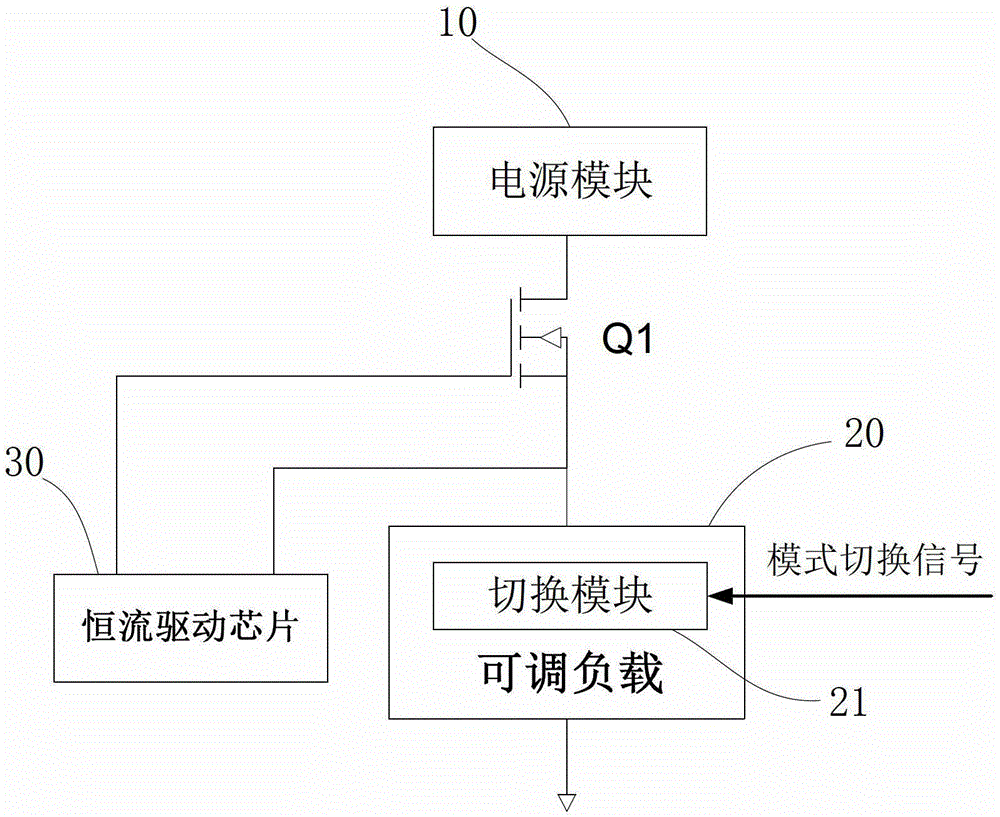

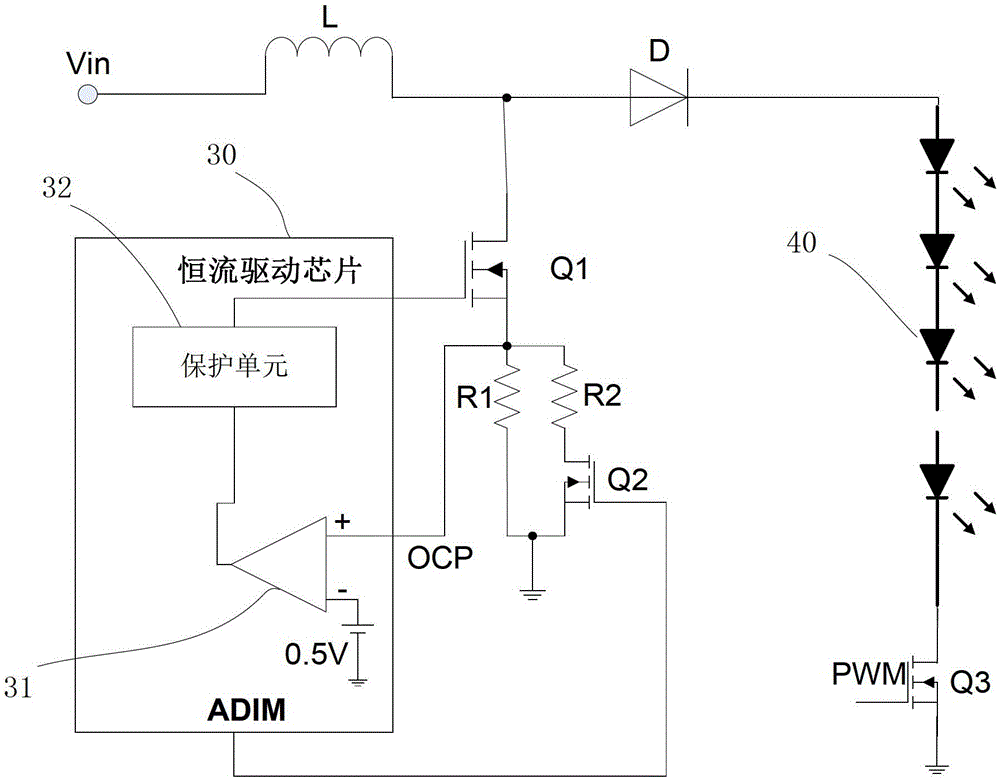

[0030] Such as image 3 , 4As shown, the backlight drive circuit disclosed in this embodiment includes a power module and a constant current drive chip 30, the power module includes a first controllable switch Q1, and an adjustable load is connected between the first controllable switch Q1 and the ground terminal of the backlight drive circuit. , the adjustable load includes a switching module that can switch different resistance values, the control end of the switching module is coupled to the mode switching signal of the backlight drive circuit; the end of the adjustable load connected to the first controllable switch Q1 is coupled to the constant current drive chip 30 overcurrent protection port.

[0031] The adjustable load includes a first resistor R1 and a second resistor R2 connected in parallel, the switching module includes a second controllable switch Q2, and the second controllable switch Q2 is connected in series between the second resistor R2 and the ground termi...

Embodiment 2

[0042] Such as Figure 5 As shown, this embodiment discloses a driving method of the backlight driving circuit of the present invention. Include steps:

[0043] A. Determine the display mode of the backlight drive circuit. If it is a 2D display mode, go to step B; if it is a 3D display mode, go to step C;

[0044] B. The mode switching signal controls the switching module to switch to the resistance value corresponding to the 2D overcurrent protection threshold;

[0045] C. The mode switching signal controls the switching module to switch to the resistance value corresponding to the 3D overcurrent protection threshold;

[0046] The adjustable load can adopt the scheme of connecting resistors in parallel, specifically, the adjustable load includes a first resistor and a second resistor connected in parallel, the switching module includes a second controllable switch, and the second controllable switch is connected in series between the second resistor and ground between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com