motor control unit

A control device, motor technology, applied in the direction of motor control, AC motor control, control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

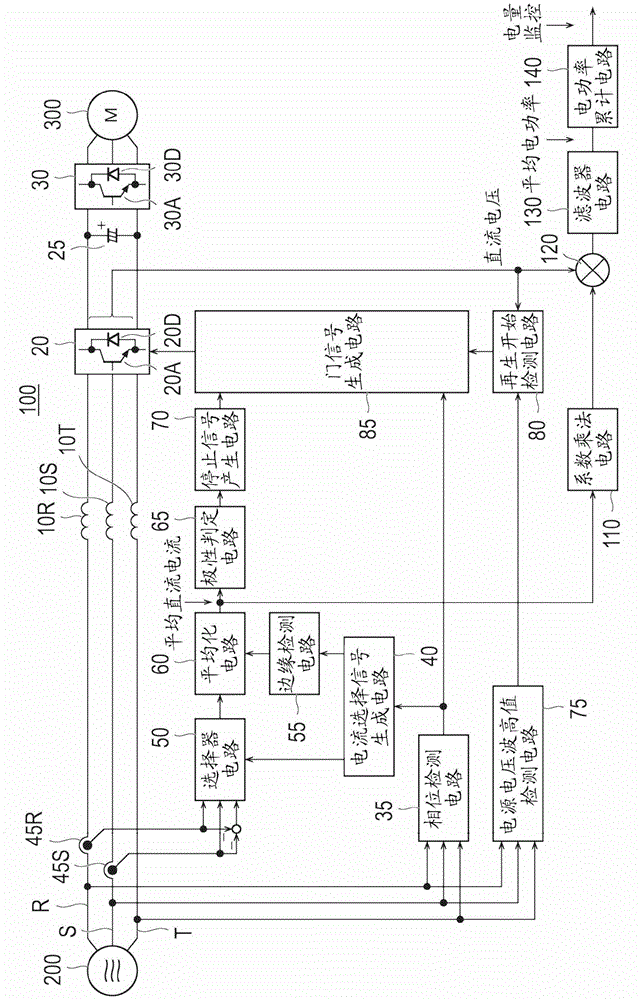

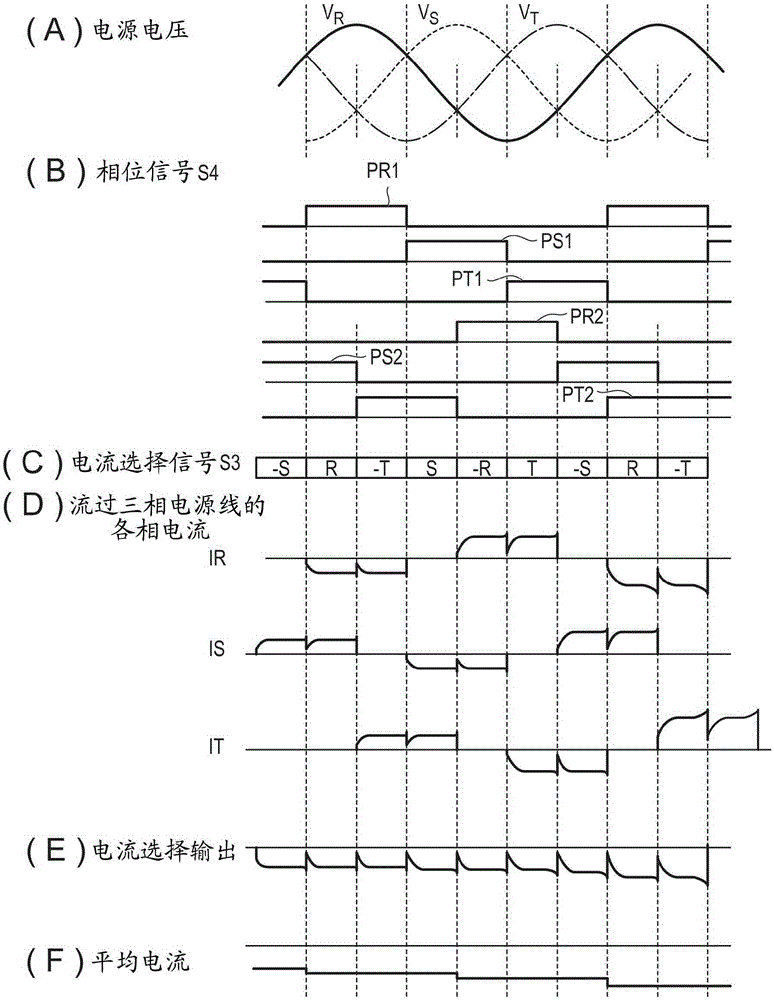

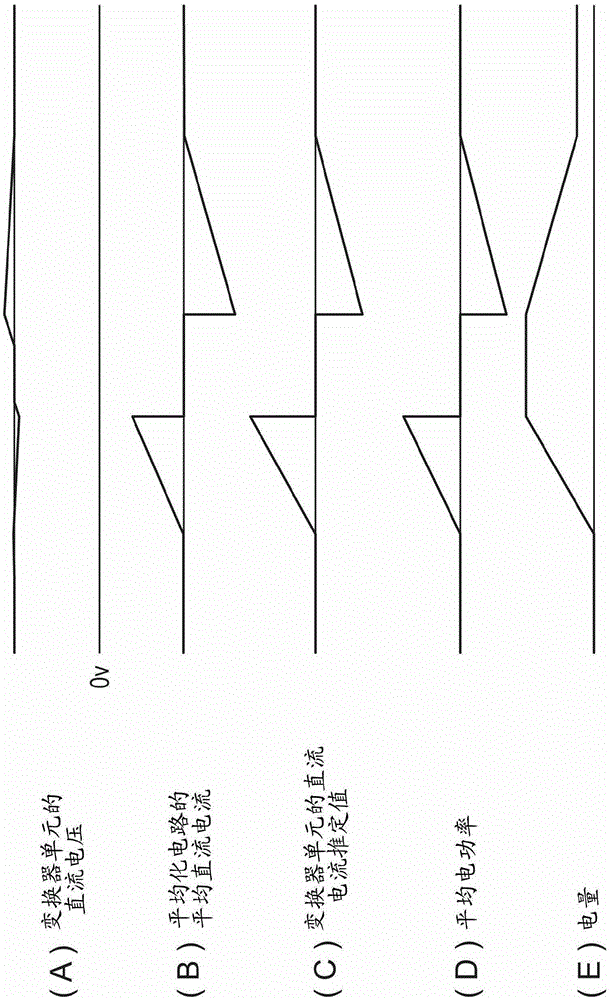

[0048] Next, the motor control device according to this embodiment will be described. figure 1 It is a block diagram of the motor control device of this embodiment.

[0049] [Configuration of motor controller]

[0050] Motor control device 100 includes reactors 10R, 10S, and 10T, inverter unit 20 , capacitor 25 , and inverter unit 30 in order to supply electric power to motor 300 .

[0051] Reactors 10R, 10S, and 10T are connected in series between three-phase power supply 200 and converter unit 20 on respective three-phase power supply lines R, S, and T connecting three-phase power supply 200 and converter unit 20 . The reactors 10R, 10S, and 10T adjust the currents flowing through the three-phase power lines R, S, and T, respectively.

[0052] The converter unit 20 converts the alternating current from the three-phase power supply 200 into direct current. The inverter unit 20 is configured by bridge-connecting six semiconductor switching elements. The semiconductor switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com