Underground plant for planting mushroom

A mushroom and factory technology, applied in the field of vegetable production facilities, can solve the problems of slow effect, poor environment, and inability to form large-scale planting, and achieve the effect of quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

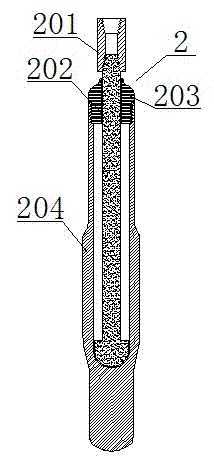

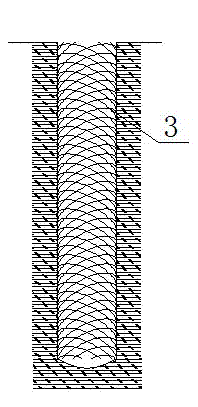

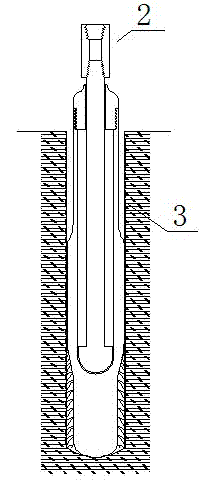

[0030] Such as figure 1 , figure 2 and Figure 5 Shown: an underground factory for planting mushrooms, characterized in that: it includes a vertical shaft 1 arranged underground, the wall of the vertical shaft 1 is provided with a mesh wall pipe 3, and the mushroom rod protection basket 4 is hoisted in the vertical shaft 1.

[0031] see Figure 7 , Figure 8 , Figure 9 and Figure 10 Mushroom bacteria rod protection basket 4 is a frame structure as a whole, which includes: vertical protection basket main frame 402, vertical protection basket main frame 402 includes upper main disk 408, lower main disk, upper main disk 408 and lower main disk Several support strips 407 distributed around the upper and lower main coils are welded between the coils, and a plurality of spacer plates 404 are distributed on the support bars 407 between the upper main coil 408 and the lower main coil, and each spacer plate The periphery of 404 is provided with an orientation plate 403 through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com