Plastic fuel tank installation fixing structure

A fixed structure and fuel tank technology, which is applied in the layout, power plant, transportation and packaging combined with the fuel supply of the internal combustion engine, can solve the problems of uneven force on the fuel tank, the stability of the fuel tank, and avoid heavy sinking, The effect of uniform force and avoiding deformation of the bottom of the fuel tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

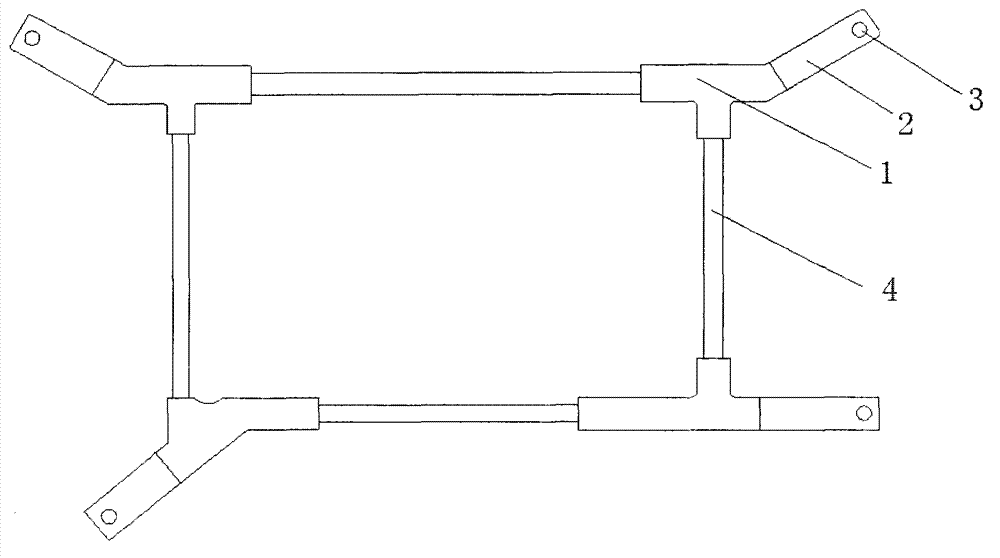

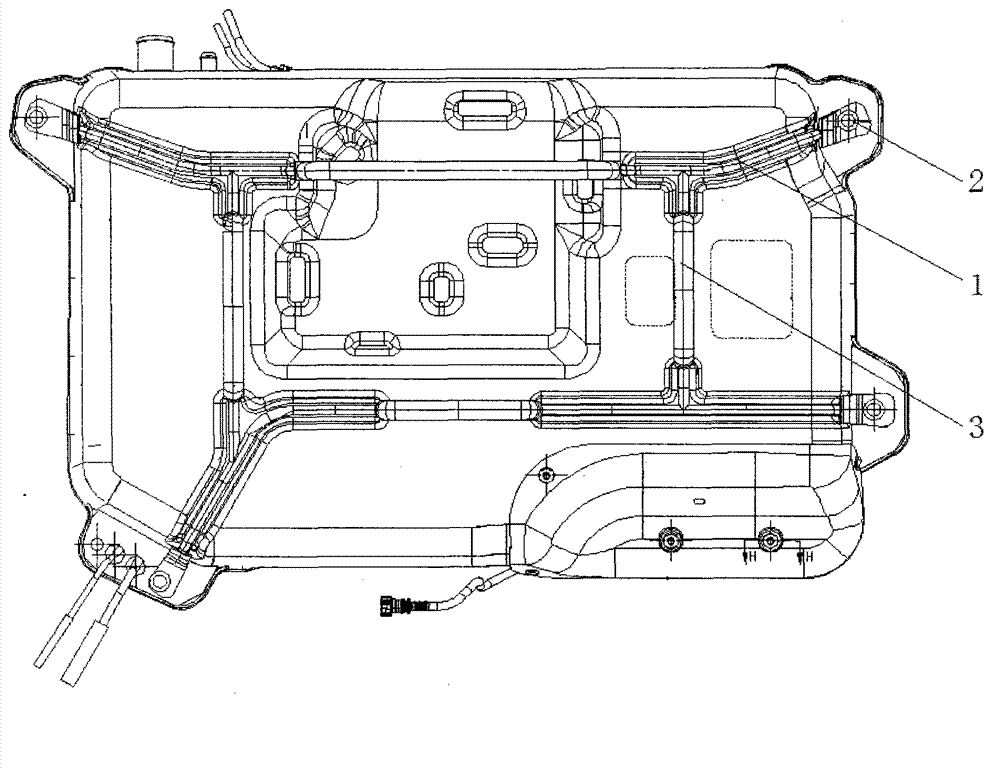

[0012] A plastic fuel tank installation and fixing structure, including a tooling bracket 1, a mounting lug 2, a fixing hole 3 and a bracket 4: It is characterized in that: one end of the tooling bracket 1 is connected to the installation lug 2 by welding, and the other end is set It is a structure of two ports, the fixing hole 3 is arranged on the mounting lug 2, the hole position and aperture of the fixing hole 3 are consistent with the installation hole of the fuel tank, and are connected by bolts to improve the stability of the fuel tank. The number of the brackets 4 is four, and the two ends are respectively connected with the tooling bracket 1 to form a rectangular structure, so that the fuel tank is evenly stressed, the stability of the fuel tank is increased, and the deformation of the bottom of the fuel tank is avoided. Improved fuel tank safety...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com