Low-noise separation mechanism for separating appendage of self-governing underwater vehicle

A technology for underwater vehicles and separation mechanisms, which can be used in underwater operation equipment, applications, clothing, etc. It can solve the problems of blasting splash and loud noise, and achieve the effect of rapid release process, low noise and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

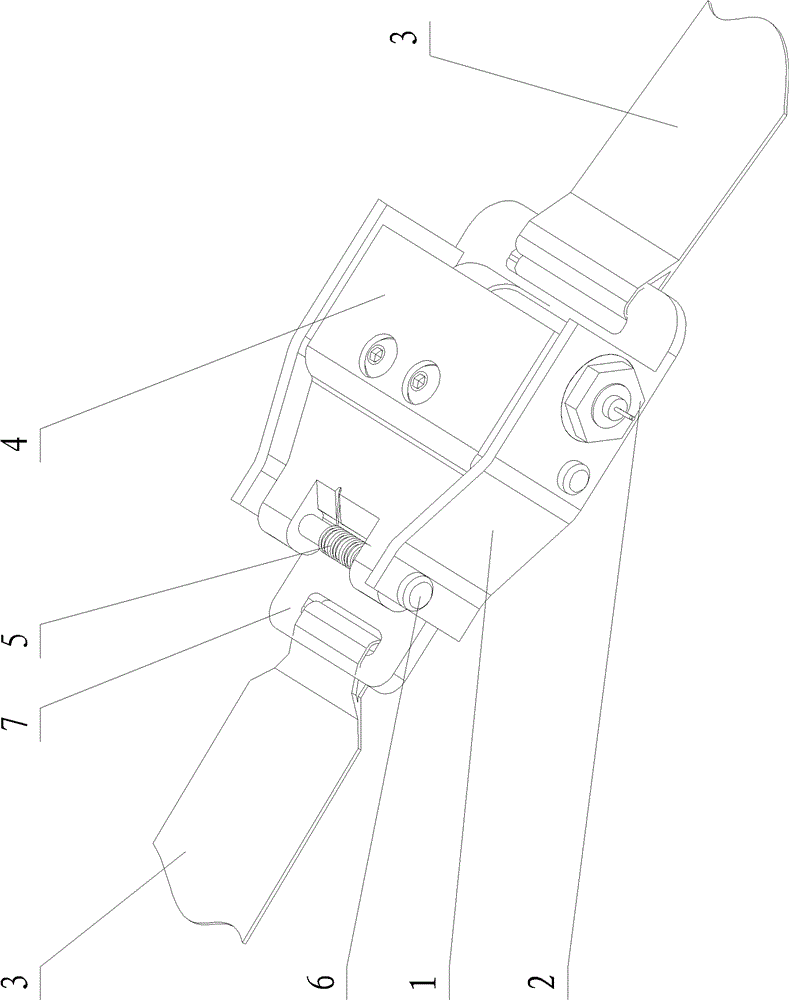

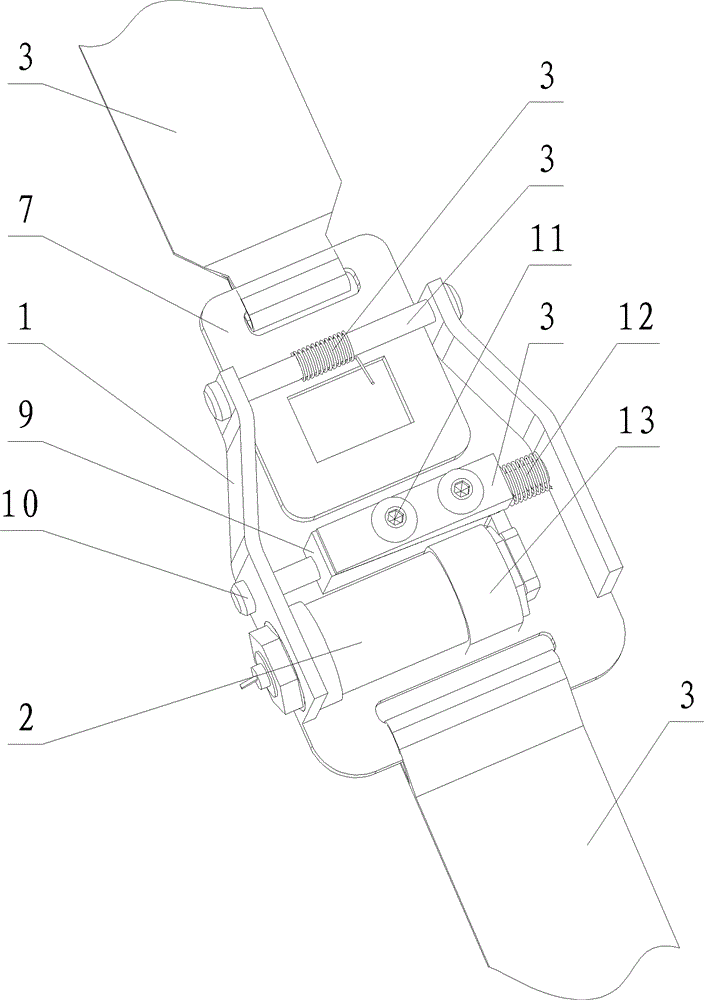

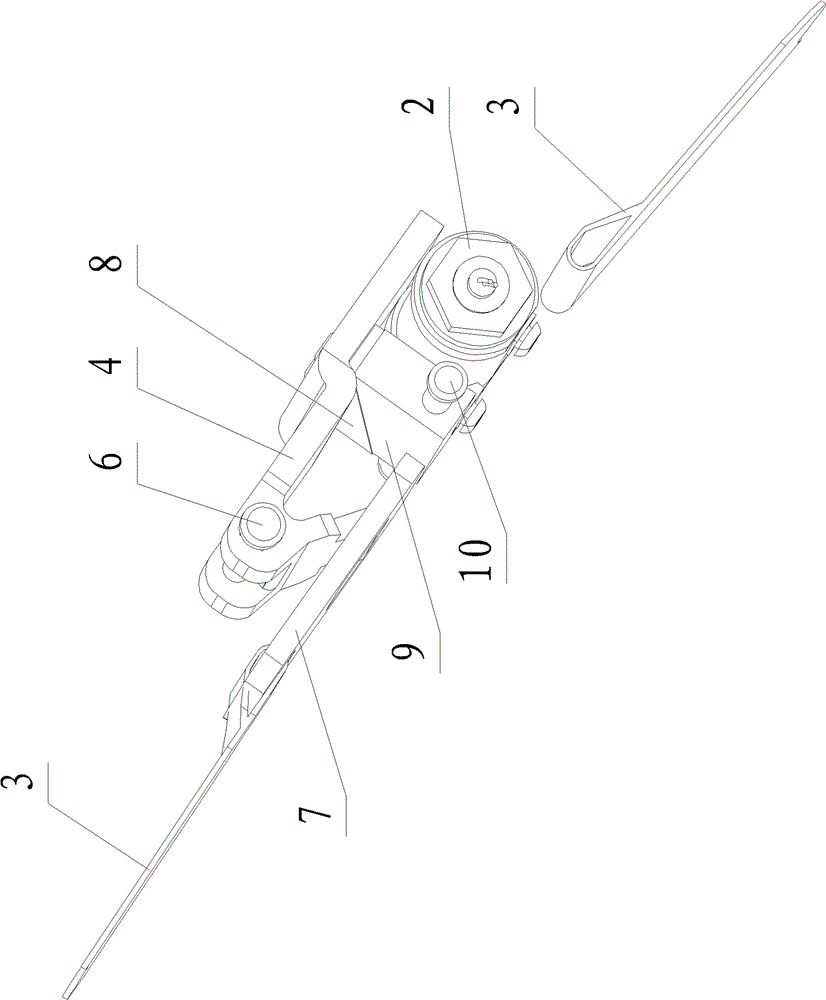

[0020] The separation mechanism of the present invention generally includes a body 1, a pyrotechnic action mechanism 2 fixed on the body 1 and related connecting and separating parts, specifically as Figure 1~3 As shown, it includes body 1, pyrotechnic action mechanism 2, connection buckle 4, torsion spring 5, torsion spring pin 6, connection tab 7, upper wedge 8, lower wedge 9, wedge pin 10 and compression Spring 12, wherein the torsion spring pin 6 is installed on the body 1, the two wing-end roots of the torsion spring pin 6 are made square, and the remainder is cylindrical, and the two square wing-end roots of the torsion spring pin 6 are respectively and The square hole that body 1 both sides offer cooperates, and is inserted in the square hole, to prevent the rotation of torsion spring pin 6 after being contained on the body 1. The connecting buckle 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com