Blade hanger device of wind turbine generator

A technology for wind turbines and spreaders, which is applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of inability to hoist and wind turbine blades without lifting points, etc., and achieves the effect of high disassembly and assembly efficiency and low maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

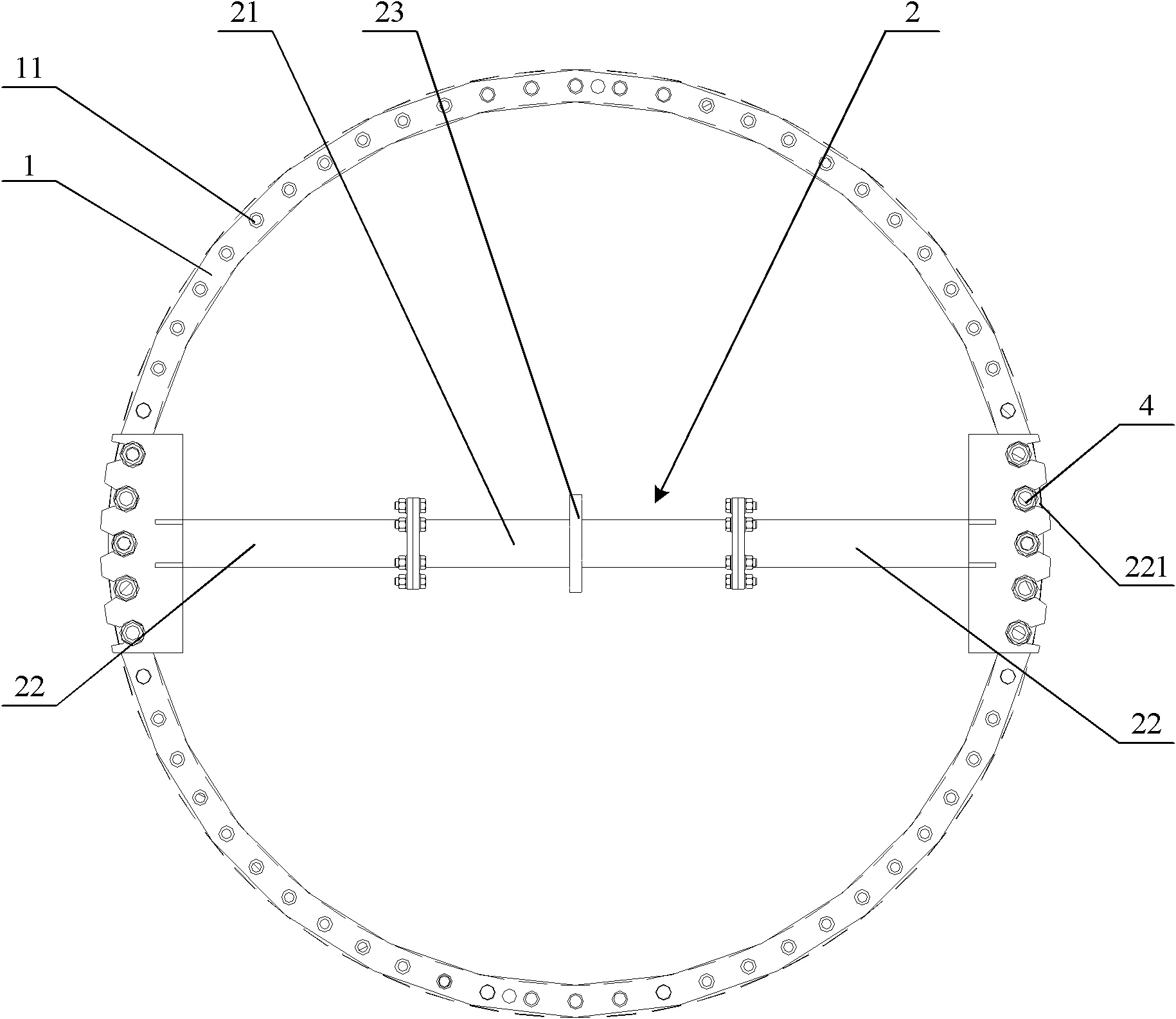

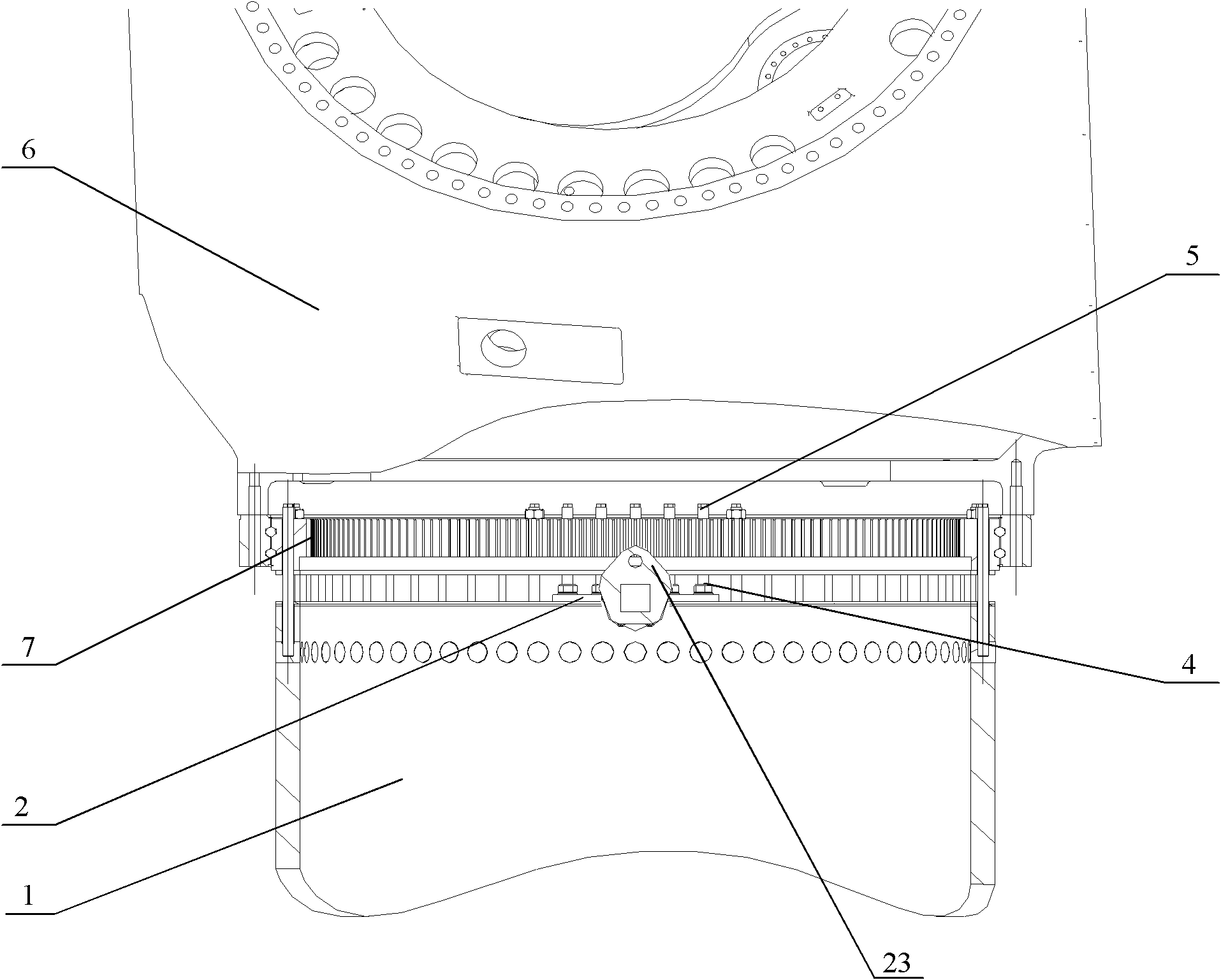

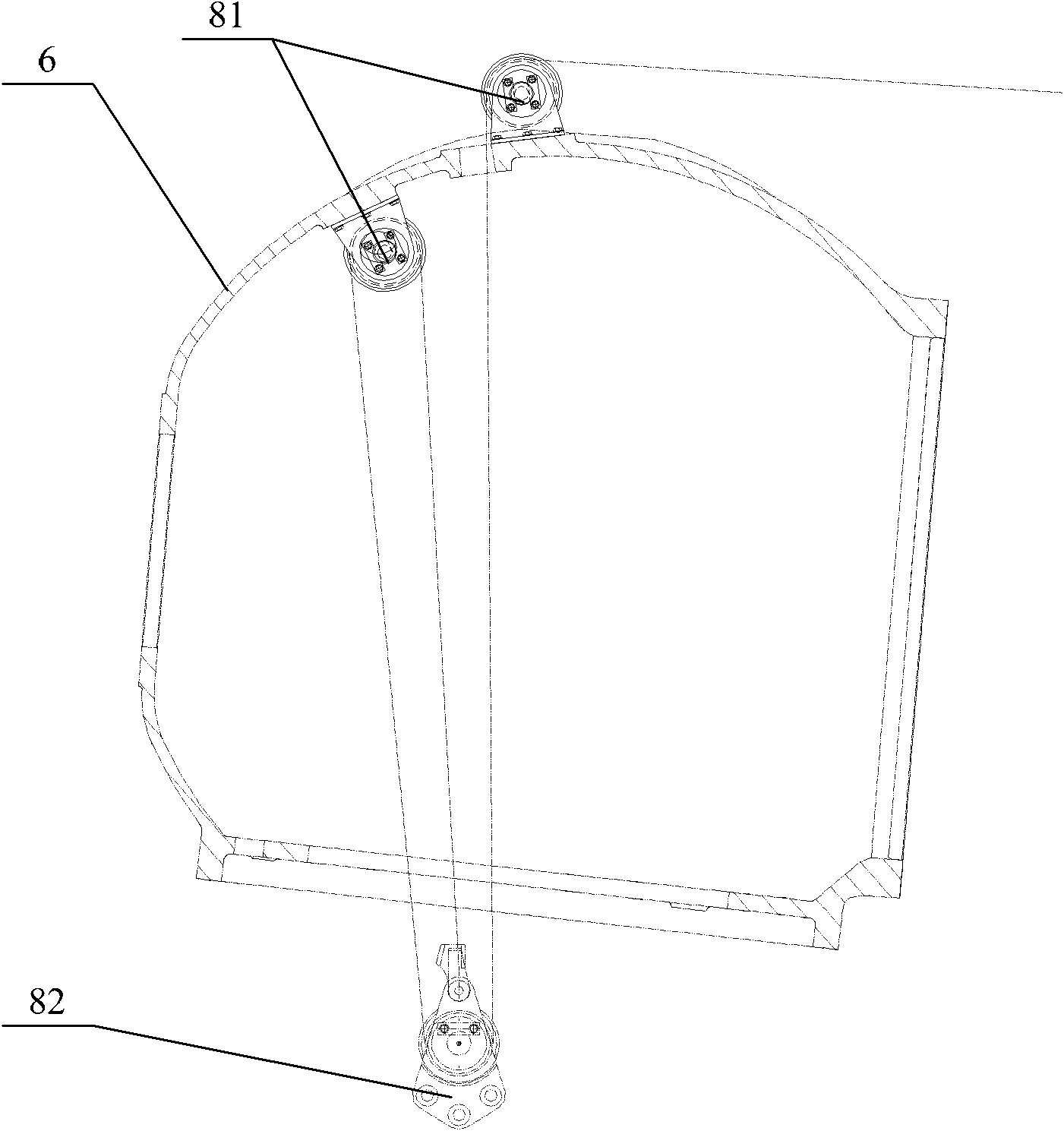

[0019] reference figure 1 with figure 2 , figure 1 It is a schematic diagram of the spreader device provided on the blade according to the first embodiment of the present invention; figure 2 It is a schematic diagram of the spreader device provided by the first embodiment of the present invention during the installation process.

[0020] Such as figure 1 with figure 2 As shown, in this embodiment, the spreader device includes a hanger 2, a plurality of first studs 4, and a plurality of second studs 5; both ends of the hanger 2 are provided with threaded holes 11 at the root of the blade 1. The corresponding stud mounting hole 221. The second stud 5 is used to connect the variable pitch bearing 7 and the blade 1 and can form a space for accommodating the hanger 2 between the variable pitch bearing 7 and the blade 1. The length of the second stud 5 may be greater than that of the blade mounting stud. Length; the first stud 4 is used to connect the hanger 2 and the blade 1. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com