Wine glass bottle cork pressing mold

A technology for glass bottles and red wine, applied in the direction of stopper fixing, etc., can solve the problems of poor sealing of thin cork and broken cork of thick cork, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

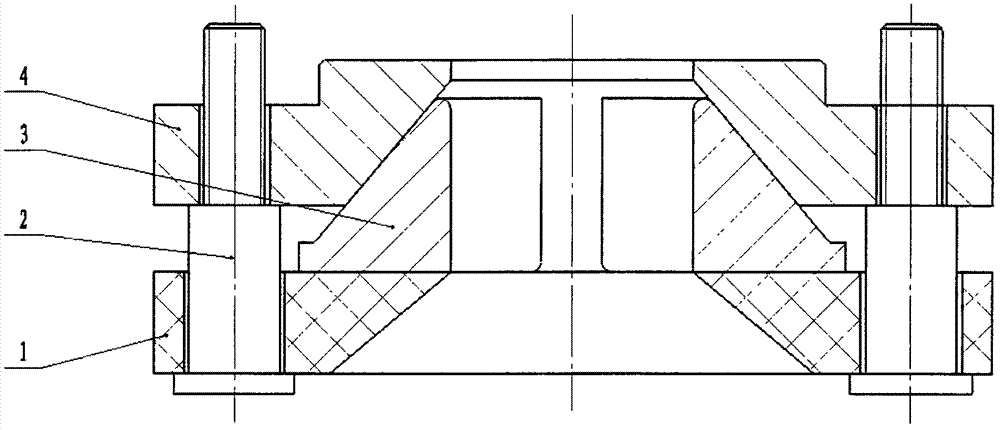

[0010] The present invention is described in detail below with reference to the accompanying drawings.

[0011] The whole process is as follows: the red wine glass bottle enters the corkscrewing device, the position of the bottle mouth is determined by the centering cover 1, when the guide rod 2 is pressed down with the corkscrewing machine, the clamping block 3 and the pressing block 4 are closed, and the clamping block 3 clamps Hold the cork, and under the action of the guide rod 2, the pressing block 4 and the clamping block 3 tightly compress the cork. During the pressing down process of the corking machine, the bottom of the cork starts to shrink and slowly presses into the inside of the bottle neck. The compressed cork The upper part of the plug is inserted into the gap between the clamp block 3 and the pressing block 4, about 10mm higher than the bottle mouth, the guide rod 2 rises, the clamp block 3 opens, the plugging die returns to the original position, and the plugg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com