UV radiation curing paint for tr90 plastic surface coating and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

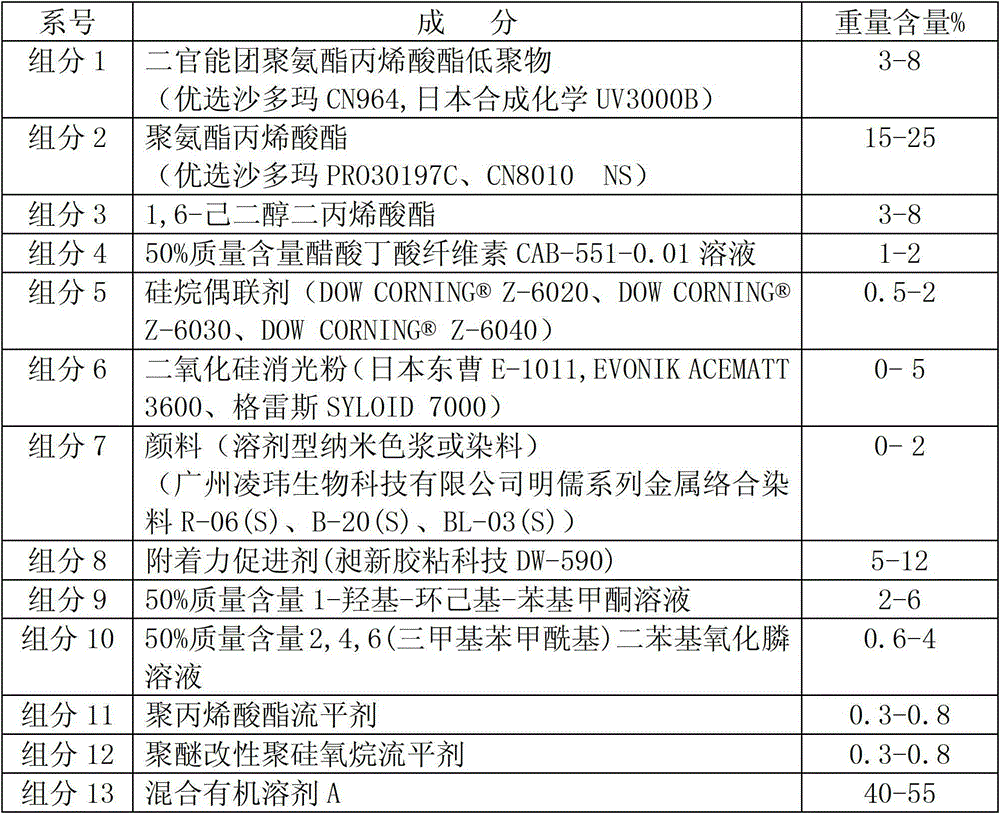

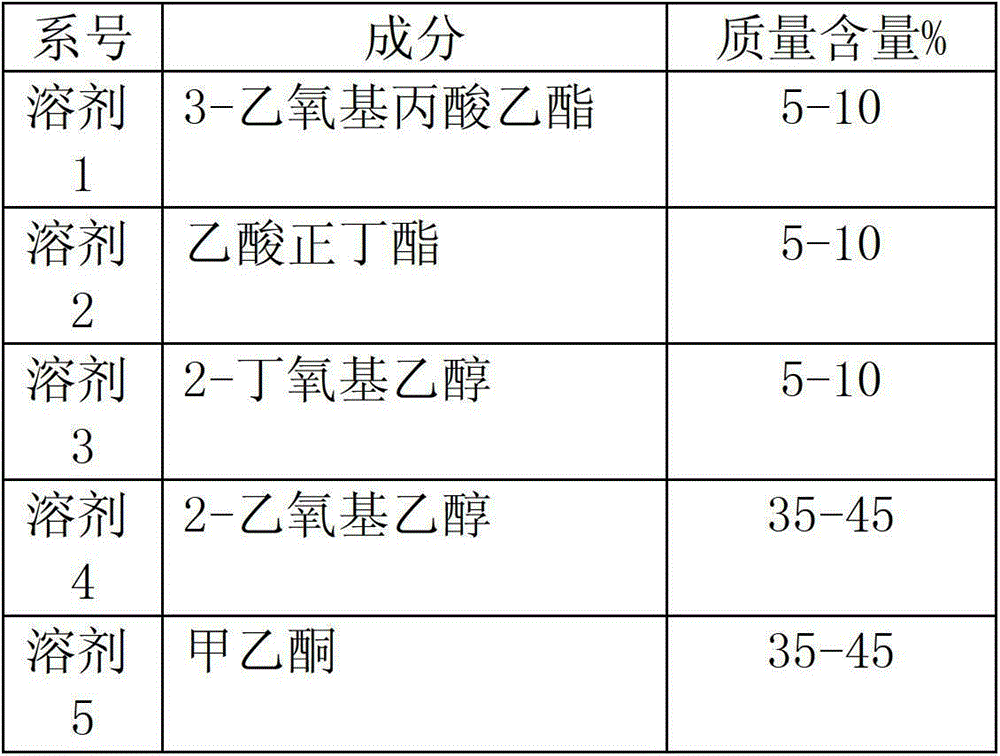

Method used

Image

Examples

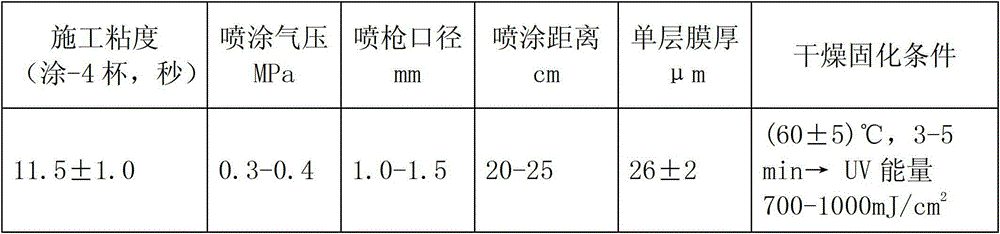

Embodiment Construction

[0037]

[0038]

[0039]

[0040]

[0041] The test results of the paint films of the above-mentioned embodiments all meet the above-mentioned technical indicators of the above-mentioned UV radiation-curable paint film that is suitable for TR90 plastic surface coating

[0042] The above embodiment solves the problem of the direct adhesion of UV coatings to TR90 substrates and can pass the bending test. The results of the coating environment simulation test are good, with good decorative and protective properties, reducing the number of constructions, improving the qualification rate of products, and saving energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com