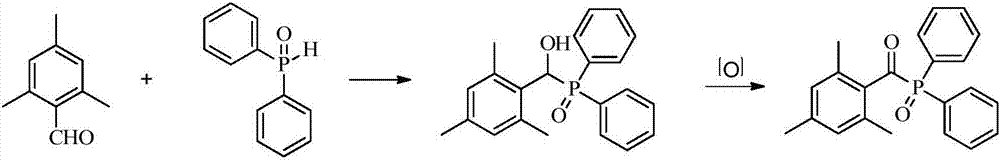

Green environment-friendly preparation method of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (TPO)

A technology of trimethylbenzoyl and diphenylphosphine oxide, which is applied in chemical instruments and methods, organic chemistry, compounds of Group 5/15 elements of the periodic table, etc., can solve the problem of high cost of organic oxidants and unfavorable industrial production , environment and product pollution, to achieve the effect of low cost, easy operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 37.61g of 2,4,6-trimethylbenzaldehyde and 56.17g of diphenylphosphine oxide into a three-necked flask containing 450mL of dichloromethane and stir, and react at room temperature (25°C) for 6 hours, and the precipitated white solid For TPO intermediates. Then put the three-necked bottle into a low-temperature water bath to cool to 8-10°C, and add 0.2309g of vanadium pentoxide (V 2 o 5 ), 37mL H 2 o 2 (mass fraction 30%), reacted at low temperature for 0.5 hours, then placed at room temperature (25° C.) for stirring, and reacted for 3 hours.

[0025] After the reaction, add 5% Na to the three-neck flask 2 S 2 o 3 Aqueous solution neutralizes unreacted H 2 o 2 , to obtain the reaction solution. Then put the reaction solution into a precipitation kettle, separate the water layer, collect the organic layer, wash three times with saturated brine, then add anhydrous sodium sulfate to remove water, then recrystallize, suction filter, and dry to obtain a light yello...

Embodiment 2

[0027] Add 37.61g of 2,4,6-trimethylbenzaldehyde and 56.17g of diphenylphosphine oxide into a three-necked flask containing 450mL of dichloromethane and stir, and react at room temperature for 6 hours. The white solid that precipitates is the TPO intermediate . Then put the three-necked bottle into a low-temperature water bath to cool to 8-10°C, and add 0.4075g of vanadyl sulfate (VOSO 4 ), 37mL H 2 o 2 (30%), reacted at low temperature for 0.5 hours, then put it under normal temperature to stir, and reacted for 4 hours.

[0028] After the reaction, add 5% Na to the three-neck flask 2 S 2 o 3 Aqueous solution neutralizes unreacted H 2 o 2 , to obtain the reaction solution. Then put the reaction solution into a precipitation kettle, separate the water layer, collect the organic layer, wash three times with saturated brine, then add anhydrous sodium sulfate to remove water, then recrystallize, suction filter, and dry to obtain a light yellow powder The solid is the TPO ...

Embodiment 3

[0030] Add 37.61g of 2,4,6-trimethylbenzaldehyde and 56.17g of diphenylphosphine oxide into a three-necked flask with 450mL of dichloromethane and stir for 6 hours, then put the three-necked flask into a low-temperature water bath to cool to 8~10℃, add 0.6126g vanadyl oxalate (VOC 2 o 4 ·5H 2 O), 37mL H 2 o 2 (30%), reacted at low temperature for 0.5 hours, then put it under normal temperature for stirring, and reacted for 5 hours.

[0031] After the reaction, add 5% Na to the filtrate 2 S 2 o 3 Aqueous solution neutralizes unreacted H 2 o 2 , extracted, collected the organic layer, washed three times with saturated brine, then added anhydrous sodium sulfate to remove water, then recrystallized, filtered with suction, and dried to obtain a light yellow powdery solid, which was the TPO product, with a yield of 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com