Tin-fried smoke guide hood structure in tin plating process

A smoke guide cover and tin plating technology, which is applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems of harsh workshop environment, no acid smoke discharge structure, etc., achieve good heat preservation effect, solve Frying tin spatter problem, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

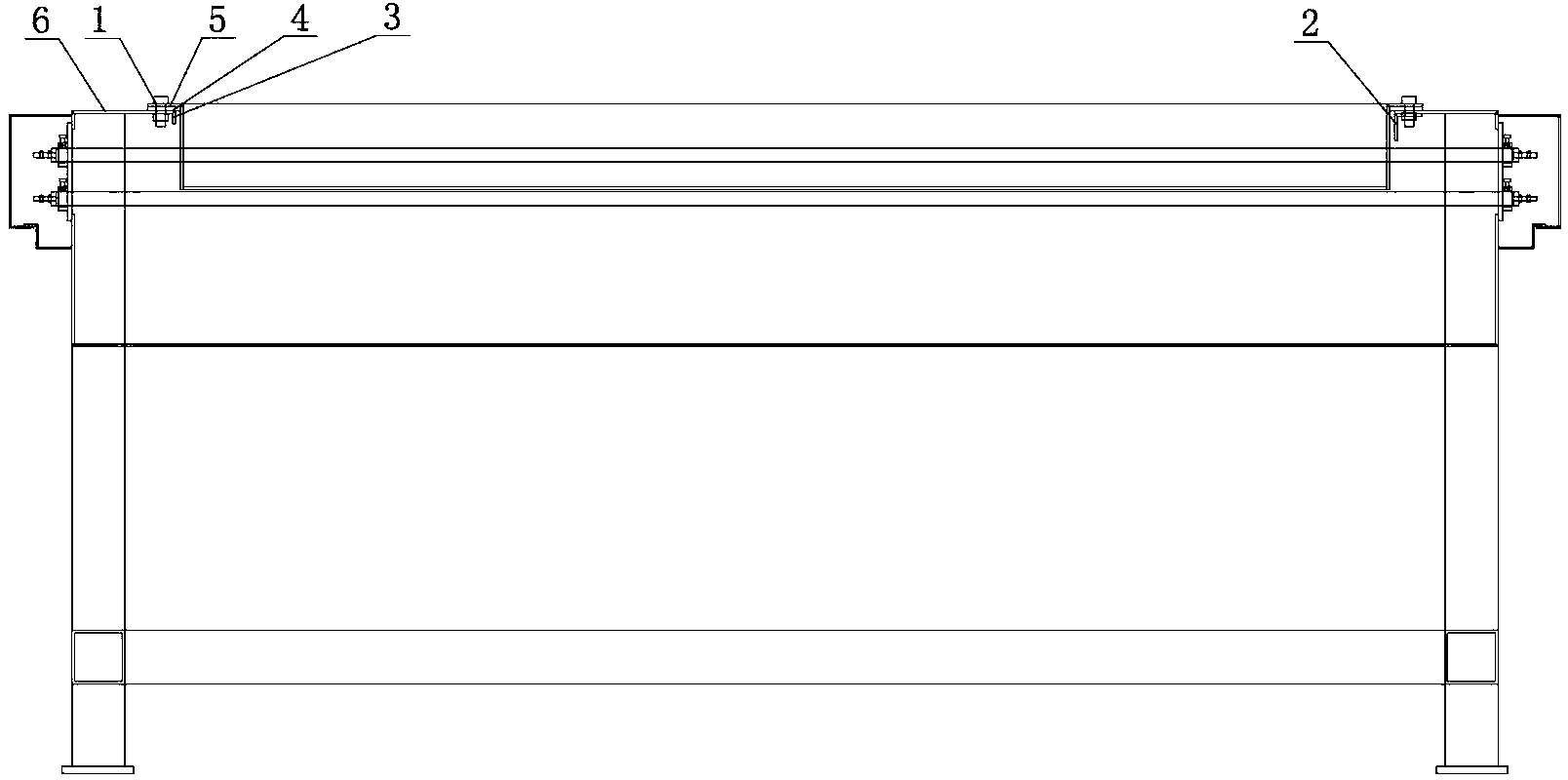

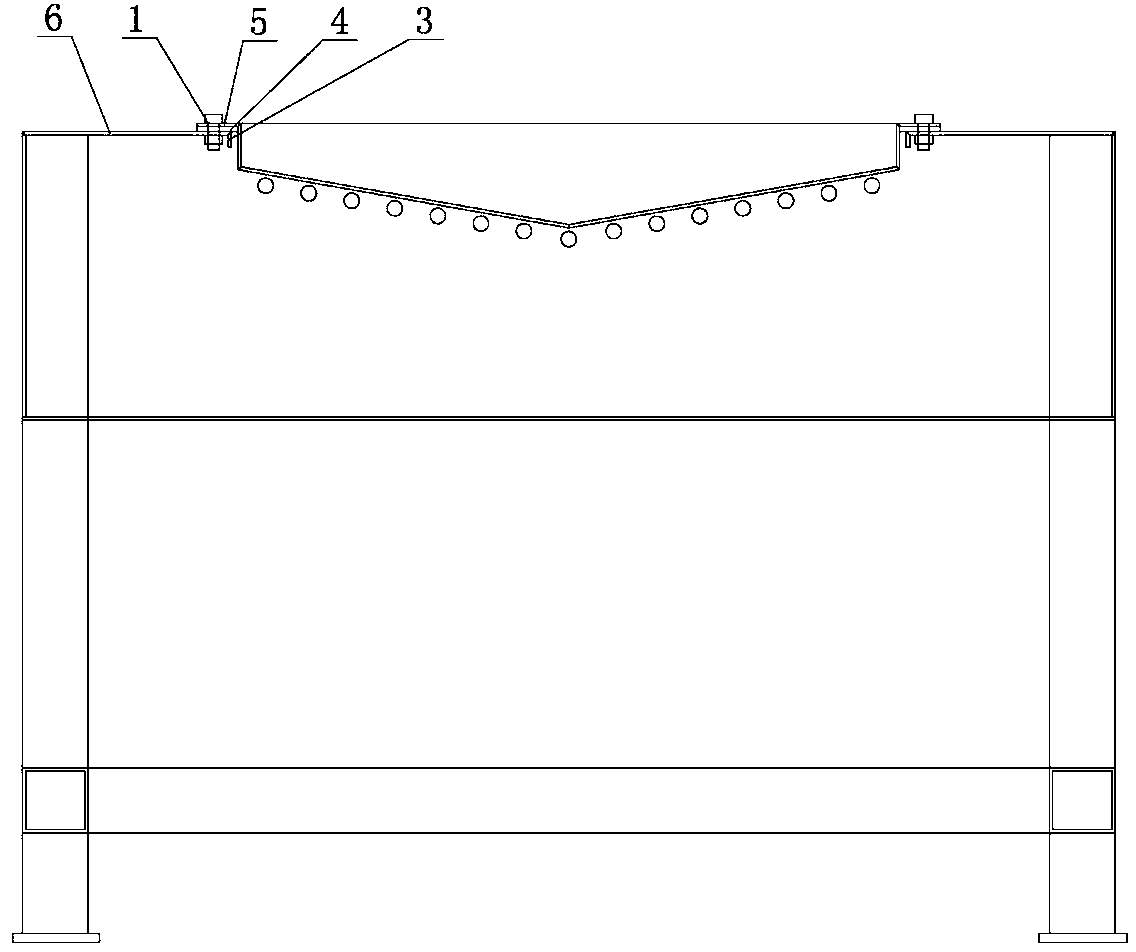

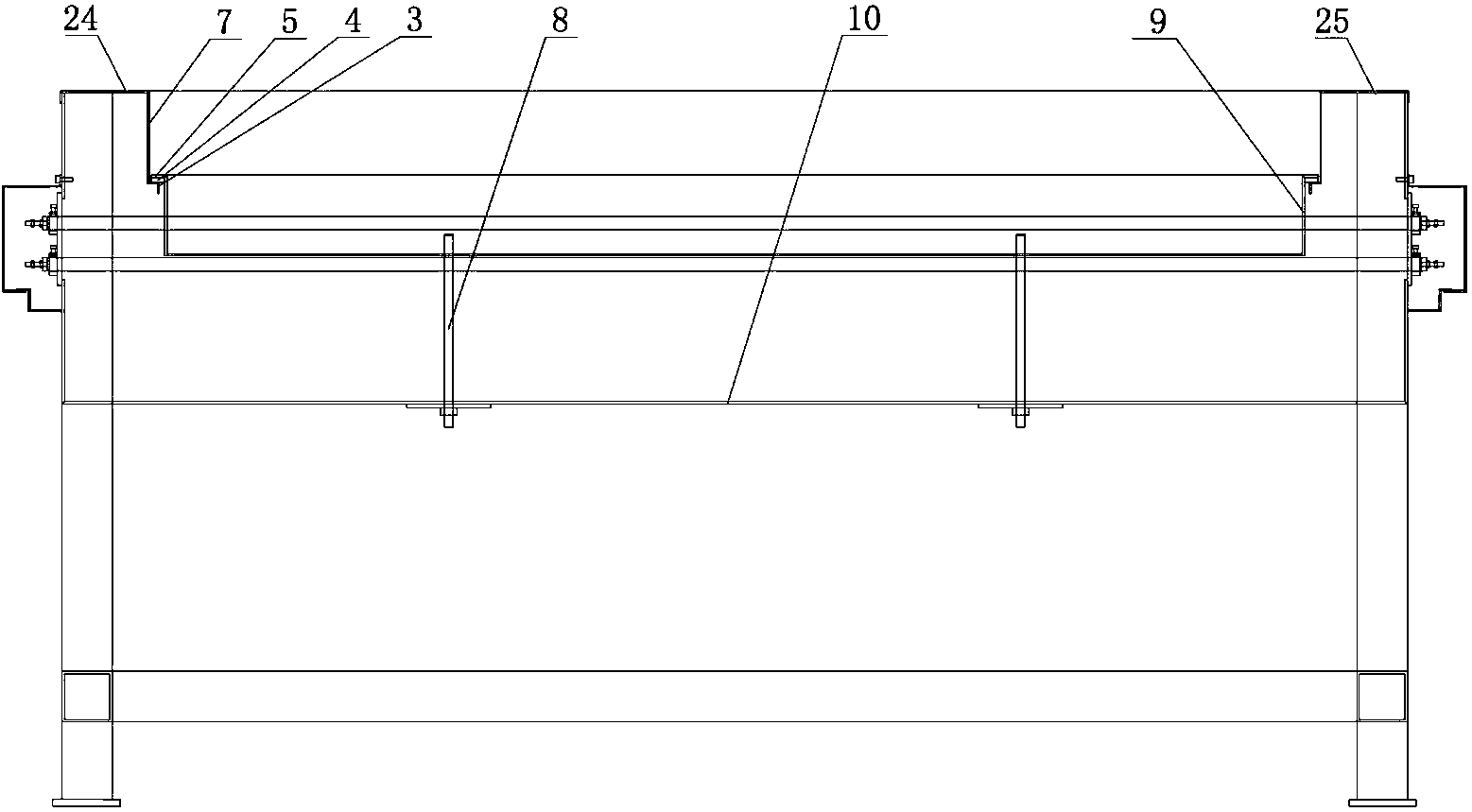

[0032] like Figure 3 to Figure 9As shown, the tin frying fume hood structure in a tinning process described in this embodiment includes a tin frying cover 14, and also includes a left turning shaft support 12, a left turning bracket 13, and a right turning shaft support 22. , the right turning bracket 23, the smoke guide cover 15 and the tin tank 16, the left turning shaft support 12 is installed on the left side table 24 in the pot edge table structure near the incoming line end of the tin pot 9, and the left turning bracket 13 Installed on the left turning shaft support 12, the right turning shaft support 22 is installed on the right side table 25 in the pot edge table structure near the incoming line end of the tin pot 9, and the right turning bracket 23...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap