Apparatus for fixing sheet member

A technology for fixing devices and components, applied to electrical components, roofs using tiles/slate tiles, solar collectors in specific environments, etc., can solve problems such as high installation costs, and achieve the effect of avoiding water infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

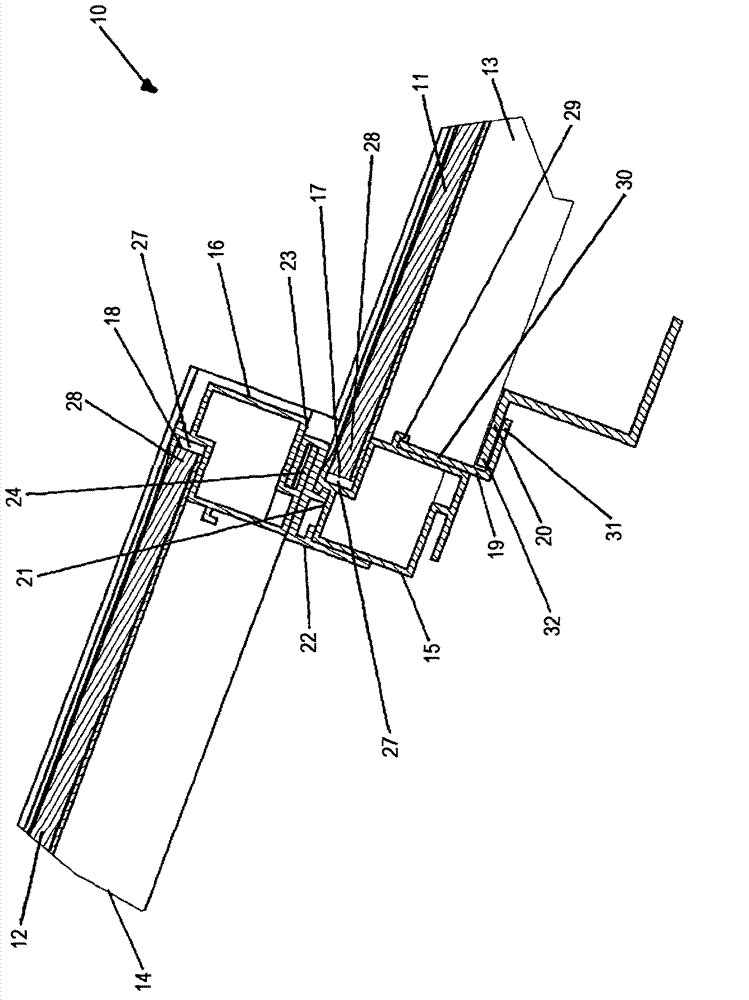

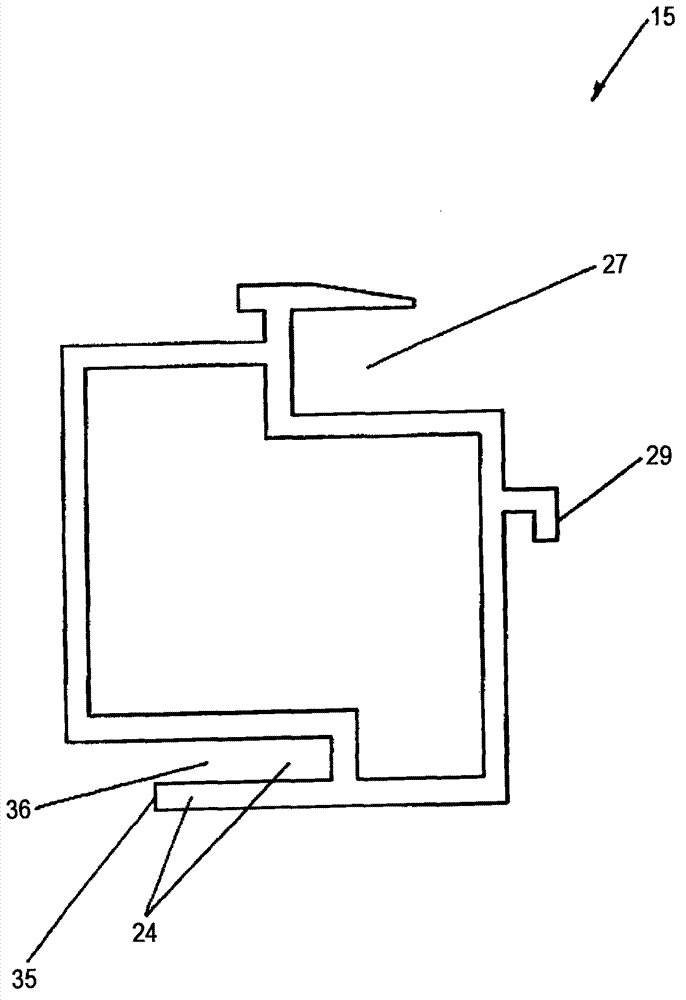

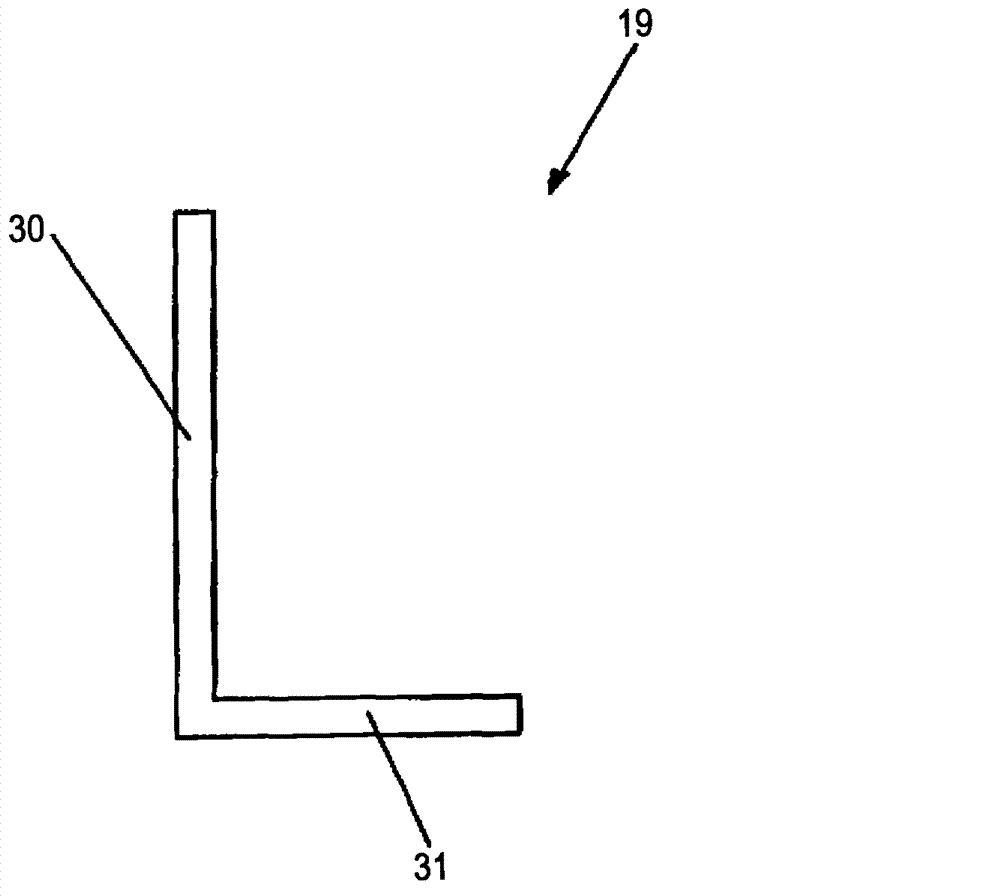

[0026] figure 1A schematic cross-sectional view of a device 10 according to the invention is shown. The device 10 comprises a plurality of laminar elements 11 , 12 , for example two laminar elements 11 , 12 . The number of lamellar elements 11, 12 is not limited by figure 1 Quantities shown are limited. Rather, the device can comprise any number of lamellar elements 11 , 12 . For example, photovoltaic modules such as thin- or thick-layer solar cells or organic solar cells, solar thermal modules such as solar collectors can be used as sheet elements 11 , 12 . Furthermore, sheet-shaped covering elements such as those made of ceramic materials or glass-like materials are also suitable. In other words, in principle any component which is at least substantially in the form of a plate is suitable. It is also possible to place the frame elements 13 , 14 according to the invention around other non-lamellar components such as skylights, in this way the skylights can be integrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com