Spring energy-storage inspiring type rotary percussive drill device

A technology of percussion drilling and spring energy storage, which is applied to the driving device of rotary combined drilling, drilling equipment, earthwork drilling and production, etc. It can solve the problems of insufficient service life, mechanism prone to failure, and small impact load amplitude, etc. Achieve reasonable installation, speed up the drilling process, and reduce drilling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

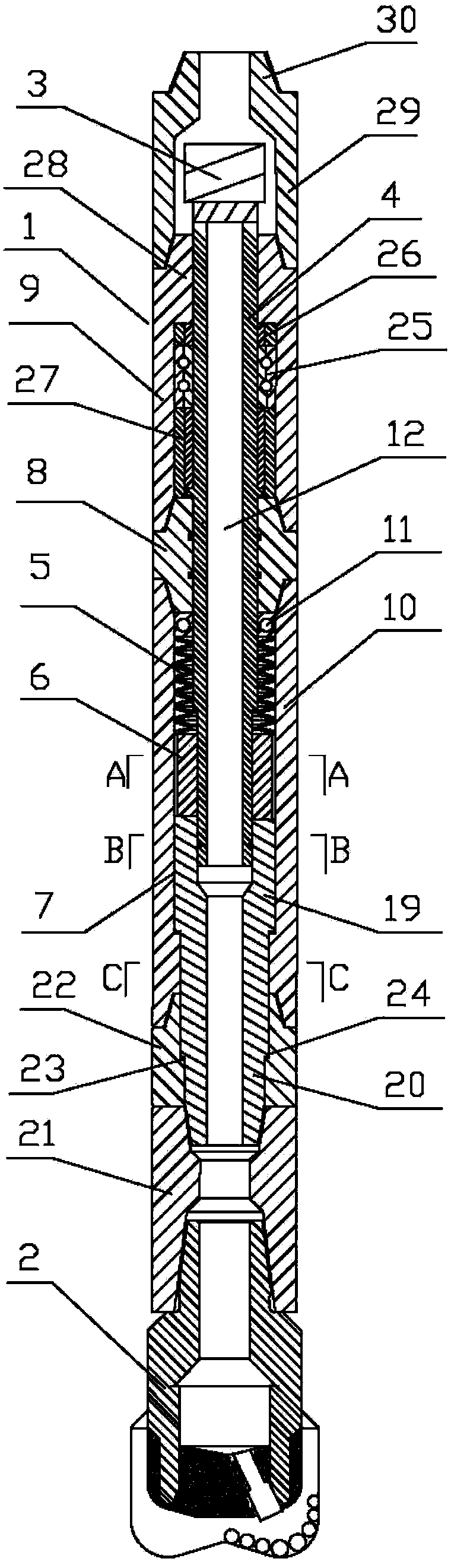

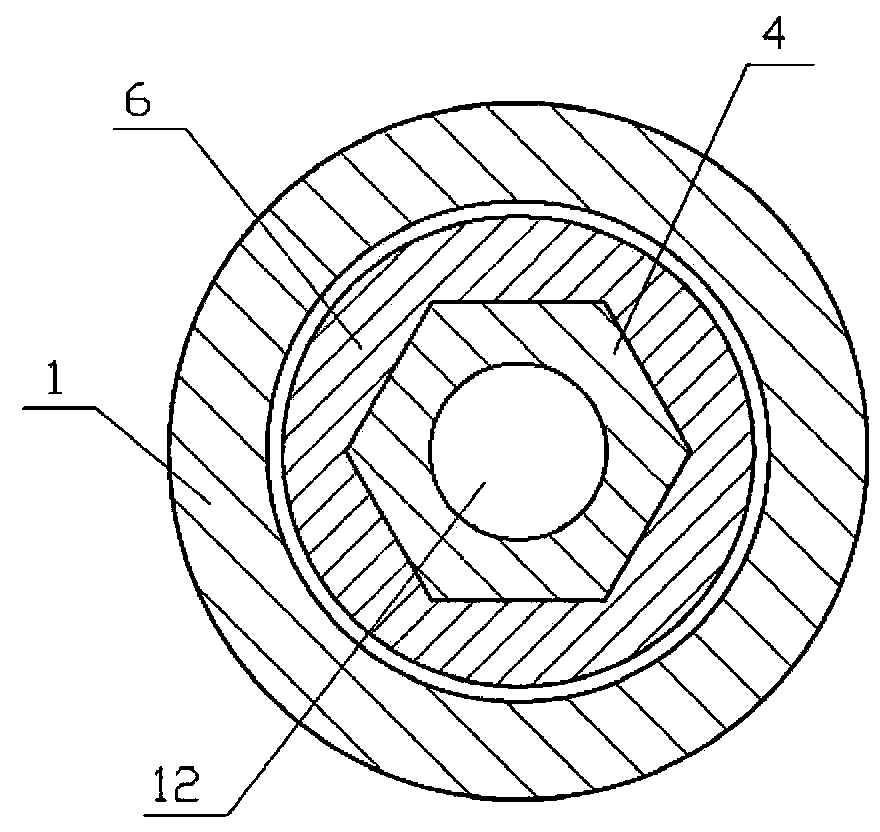

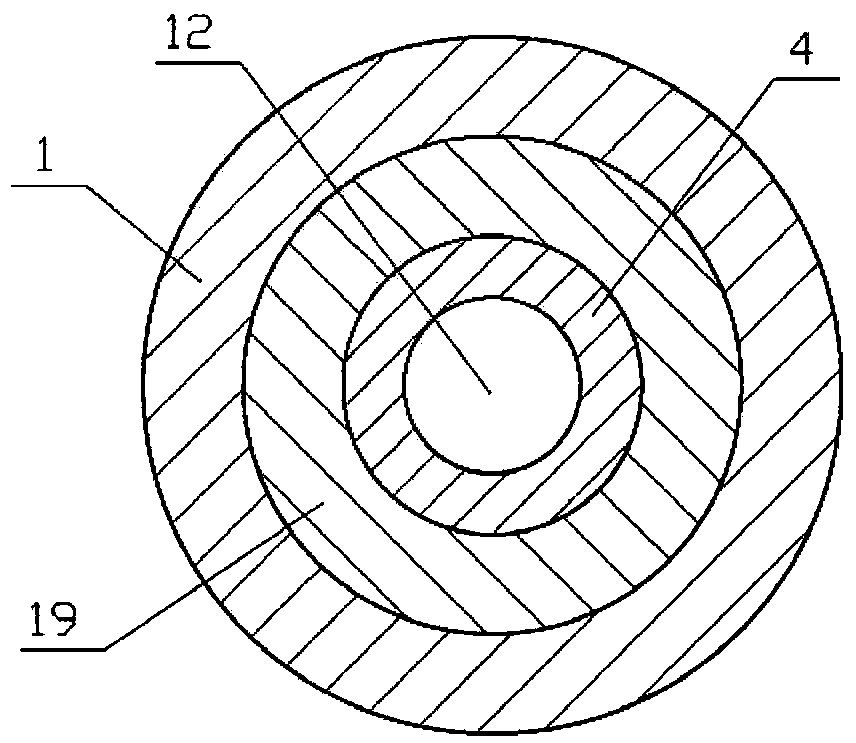

[0030] see figure 1 , figure 2 , image 3 , Figure 4 As shown, the spring energy excitation type rotary percussion drilling device of the present invention includes a downhole motor (belonging to the prior art, not shown in the figure) and a drill pipe 1 connected to the downhole motor, and a drill bit 2 is arranged at the lower end of the drill pipe In this embodiment, the drill pipe is vertically arranged at the lower end of the downhole motor, and is connected to the rotary drilling motor through threads, and the drill bit is detachably connected to the drill pipe through threads, and the drill pipe is provided with There is an impact mechanism, which is arranged coaxially with the drill pipe as a whole. The impact mechanism includes a downhole motor 3, a rotating shaft 4 arranged at the lower end of the downhole motor, and a shock and vibration kit sleeved at the lower part of the rotating shaft. The downhole motor described in this embodiment is connected to the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com