Filter device with heating device for heating medium and its use in motor vehicles

A filter device and heating device technology, applied in the direction of filter separation, noise reduction device, exhaust device, etc., can solve troublesome problems, achieve the effect of reducing injection molding cost, less material consumption, and lower price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

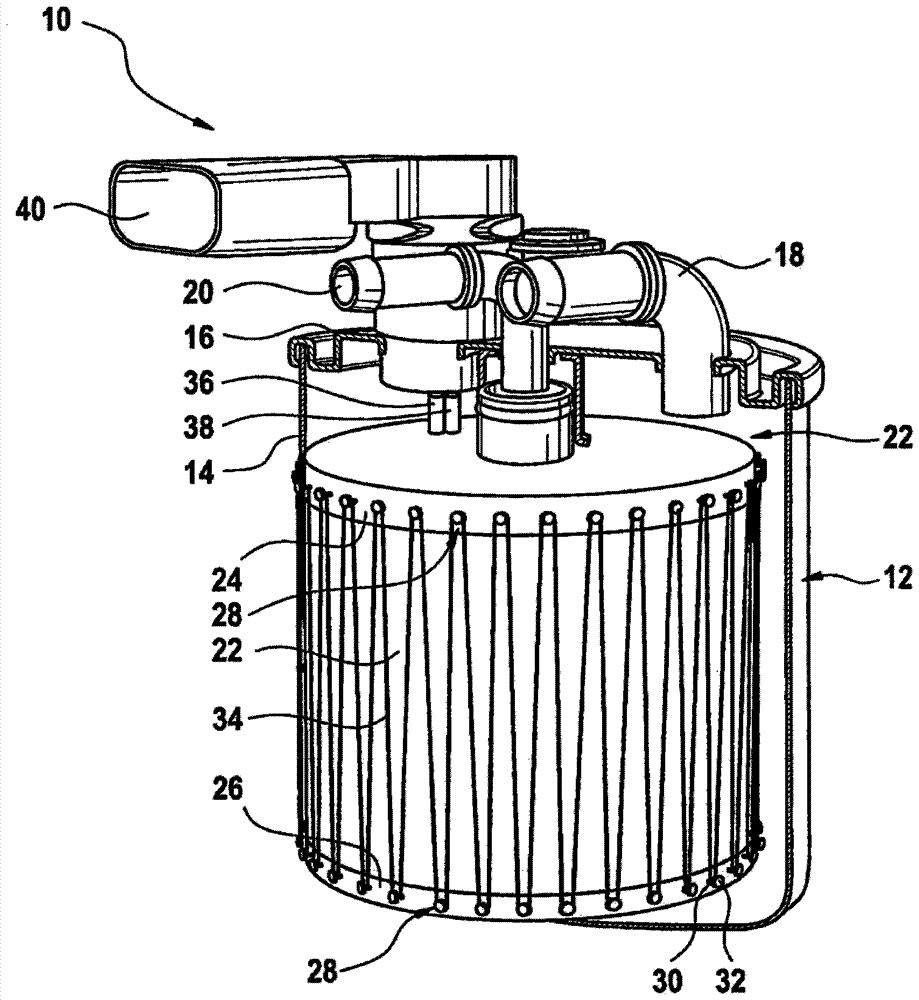

[0018] figure 1 Shown is a filter device 10 which is designed as a fuel filter for a motor vehicle. The filter device 10 is formed with a filter housing 12 formed from a cylindrical housing cup 14 and a circular housing cover 16 closing the housing cup 14 .

[0019] On the housing cover 16 there is a curved, tubular inlet 18 and an identically shaped outlet 20 , which both lead through the housing cover 16 into the interior of the housing cup 14 . In the housing cup 14 there is a hollow-cylindrical filter element 22 which separates the inlet side from the outlet side. The medium, in particular fuel, which flows into the housing cup 14 via the inlet 18 flows through the filter element 22 and removes impurities and water there. The medium then leaves the filter device 10 in purified form through the outlet 20 .

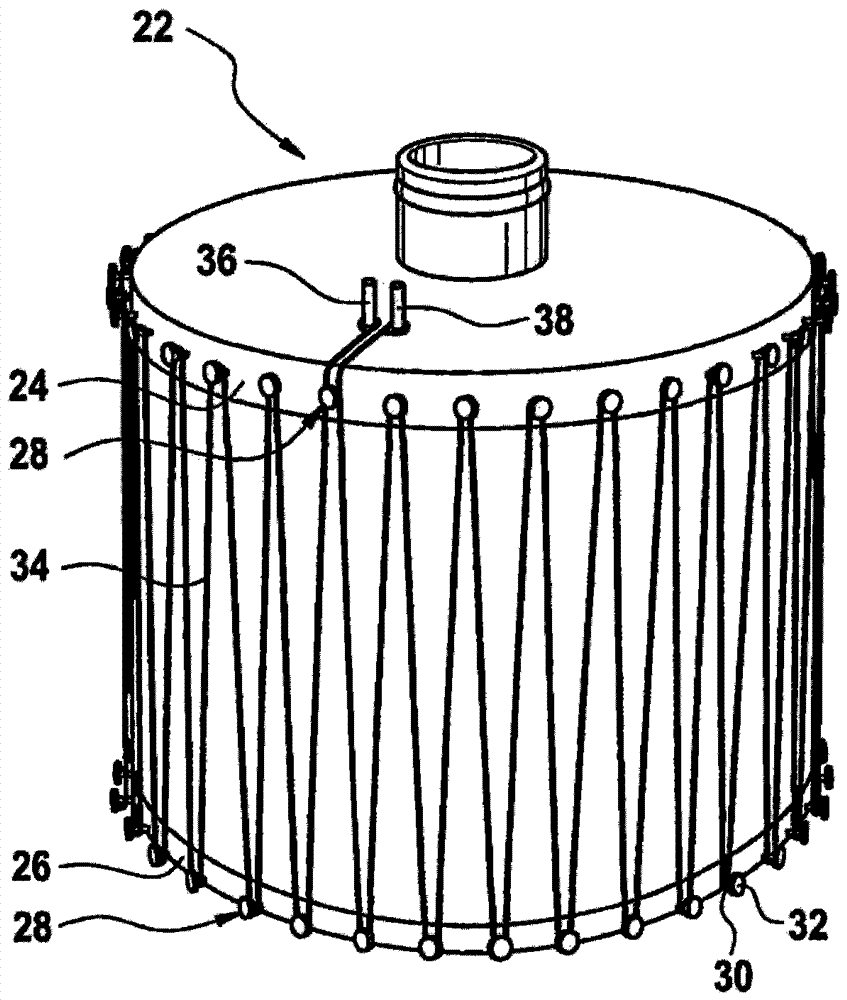

[0020] figure 2 The filter element 22 is shown in detail in . On its upper end-side edge region 24 and on its lower end-side edge region 26 , it each has a row of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com