Fuel cell energy recovery system and control method

An energy recovery and fuel cell technology, used in fuel cells, fuel cell additives, fuel cell heat exchange, etc. Pressure and other problems, to achieve the effect of high energy utilization efficiency, enhanced work ability, and fine utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

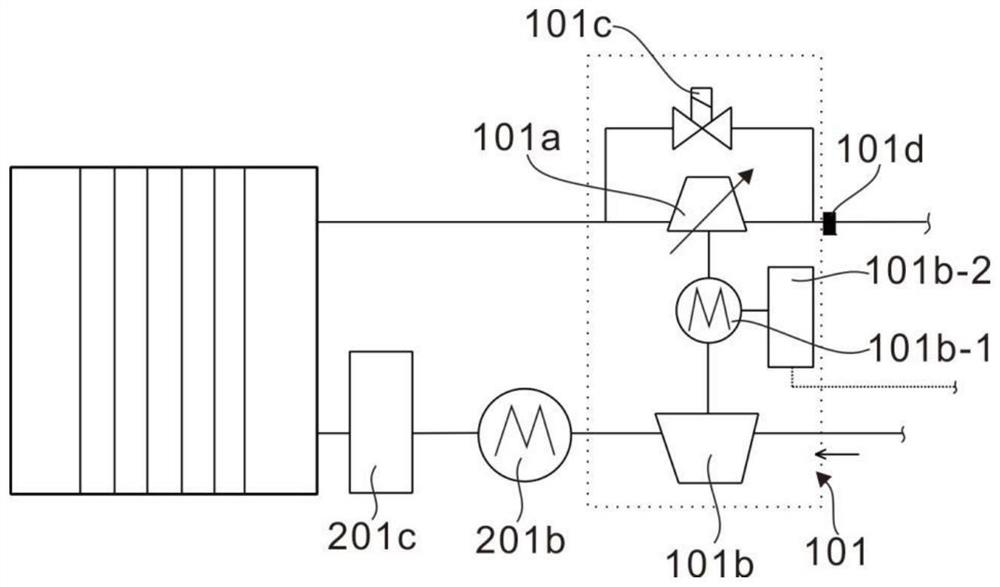

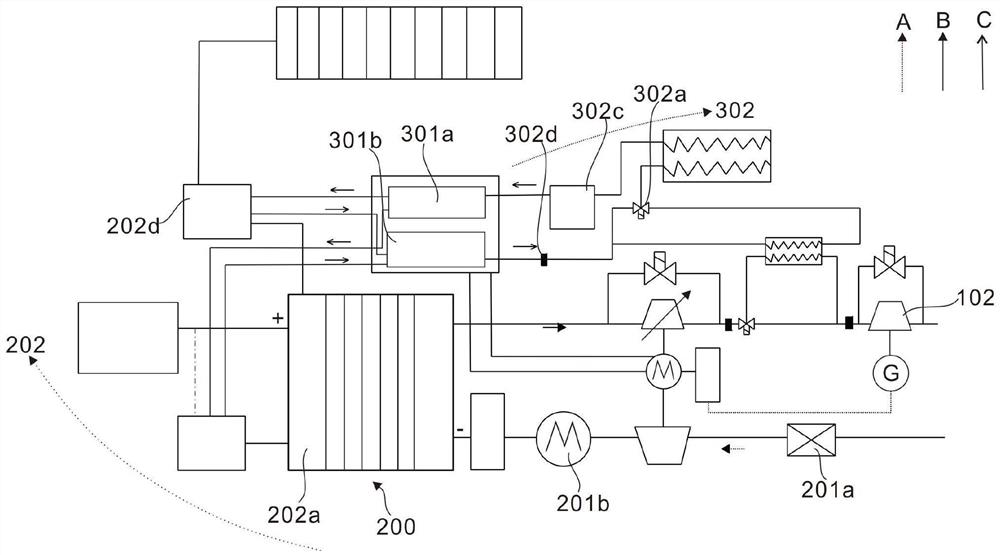

[0038] refer to Figure 1-5 and Figure 9 , is the first embodiment of the present invention, which provides a fuel cell energy recovery system, the fuel cell energy recovery system includes a recovery unit 100, and the recovery unit 100 includes a primary recovery module 101 and a secondary recovery module 102.

[0039] Specifically, the primary recovery module 101 includes a primary expansion end 101a, an air compressor 101b, and a first bypass valve 101c, the primary expansion end 101a is coaxially connected to the air compressor 101b, and the first bypass valve 101c is connected to a The two ends of the expansion end 101a of the first stage, the air compressor 101b is used for forced air intake to supply air for the fuel cell, and the high-temperature steam passes through the expansion end 101a of the first stage of the coaxial connection of the air compressor 101, using temperature, pressure and speed energy Blow the turbine in the first-stage expansion end 101a to do wo...

Embodiment 2

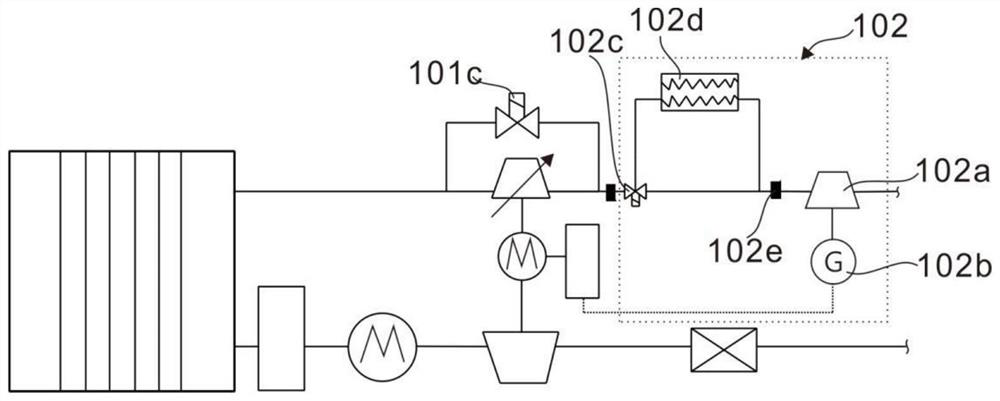

[0045] refer to image 3 and Figure 6~7 , is the second embodiment of the present invention, which is based on the previous embodiment.

[0046] Specifically, the air compressor 101b includes a motor 101b-1 and a motor controller 101b-2, the motor 101b-1 is connected to the air compressor 101b and the primary expansion end 101a, and the motor controller 101b-2 is connected to the motor 101b-1 Connected, the motor 101b-1 is used to control the start of the air compressor 101b.

[0047] Further, it also includes a fuel reaction unit 200, the fuel reaction unit 200 includes an air supply module 201, the air supply module 201 includes an air filter 201a, an intercooler 201b and a humidifier 201c, and the air filter 201a is connected to the air compressor 101b , the intercooler 201b is connected to the air compressor 101b, the humidifier 201c is connected to the intercooler 201b, the air filter 201a is used to filter the inhaled air, and the intercooler 201b is used to reduce th...

Embodiment 3

[0052] refer to image 3 and Figure 7-9 , is the third embodiment of the present invention, which is based on the first two embodiments.

[0053] Specifically, the secondary recovery module 102 also includes a first three-way valve 102c, a heat exchanger 102d and a first sensor 102e, the first three-way valve 102c is connected to the primary expansion end 101a; one end of the heat exchanger 102d is connected to the first A three-way valve 102c is connected, and the other end is connected with the secondary expansion end 102a; the first sensor 102e is arranged upstream of the secondary expansion end 102a, and the first three-way valve 102c is used to control the exhaust gas to pass through the first recovery module 101 After energy recovery, whether to exchange heat with the heat-absorbing coolant through the heat exchanger 102d? If the first three-way valve 102c is connected to the heat exchanger 102d, the exhaust gas will enter the heat exchanger 102d to exchange heat with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com