Manual wheel type steel rail ultrasonic flaw detection car

A manual wheel type, ultrasonic technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems that the ultrasonic coupling cannot be guaranteed, the rail detection cannot be guaranteed, the probe is damaged, etc., and the ultrasonic signal is good. The structure is simple and easy to implement. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

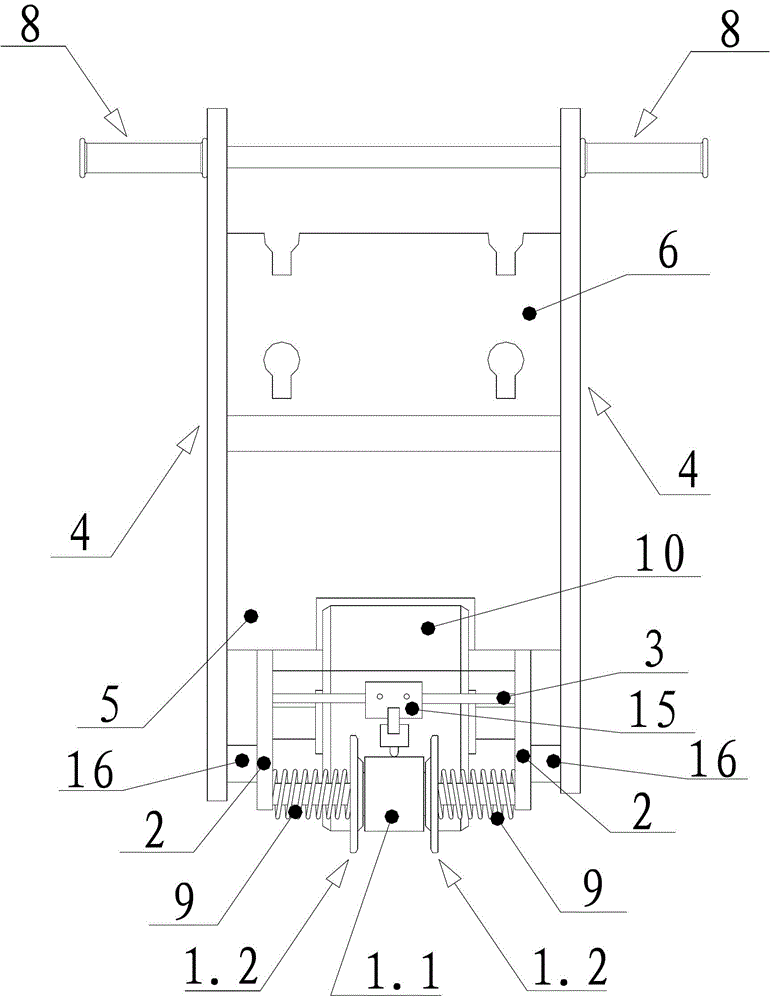

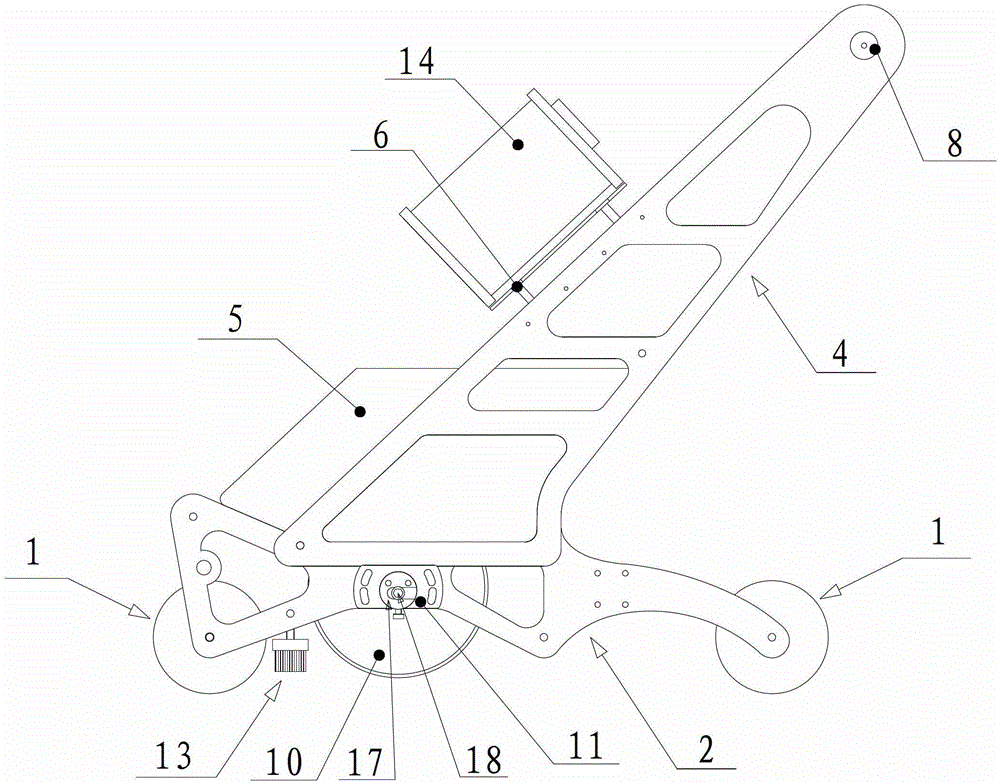

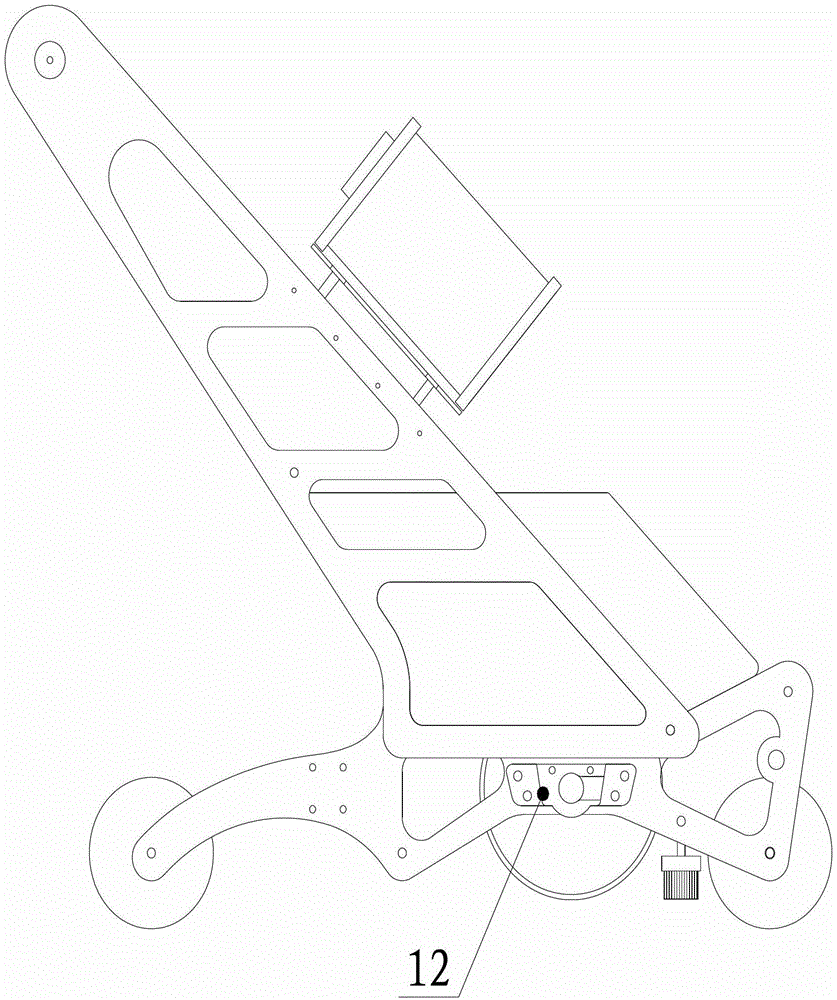

[0010] like Figure 1-4 As shown, a manual wheeled rail ultrasonic flaw detection vehicle includes a wheel chassis, a wheel probe installed between the front and rear guide wheels of the wheel chassis, and an ultrasonic flaw detector installed on the flaw detection vehicle. The front and rear guide wheels 1 are respectively composed of a roller 1.1 and a rim 1.2 with sliding bearings in the inner hole. The wheel rims on both sides of the guide wheel and the wheel axle between the wheel chassis 2 are respectively equipped with springs 9 for resisting. Press the rim so that the rims on both sides of the guide wheel are moderately pressed against the two sides of the rail, so as to avoid the left and right shaking of the guide wheel during the push and ensure the stability during the push. The axles connected to the two ends of the wheel probe 10 are installed in the shaft holes provided on the probe fixing block 12 and the probe adjusting block 11 respectively provided on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com