Carding elements

A carding element, combing machine technology, applied in the direction of combing machines, fiber processing, textiles and paper, which can solve problems such as hindering the assembly process, and achieve the effect of simplifying maintenance and/or repair operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

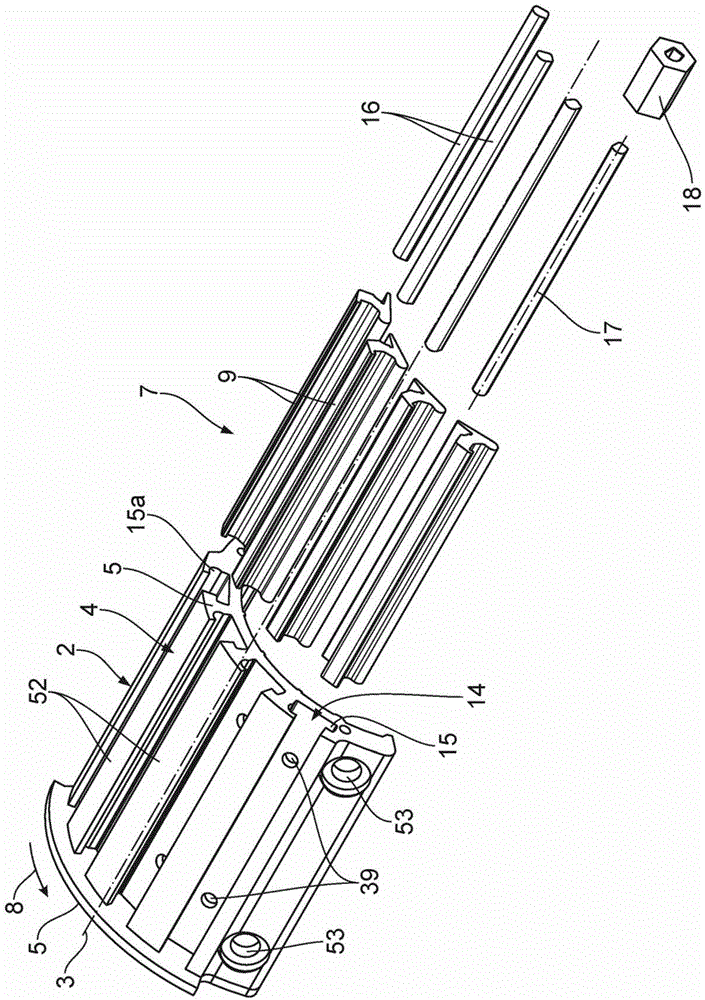

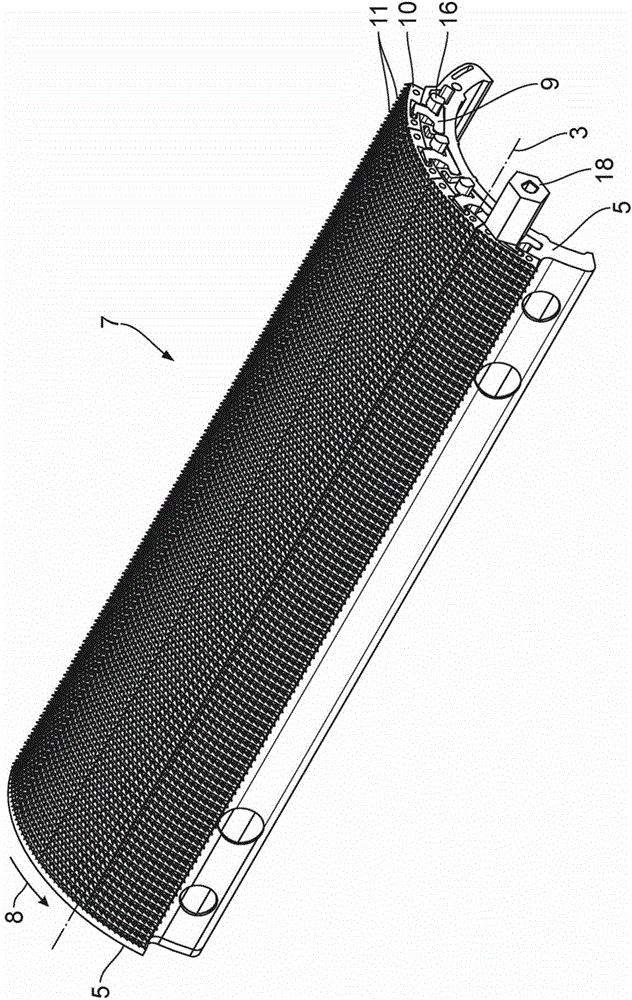

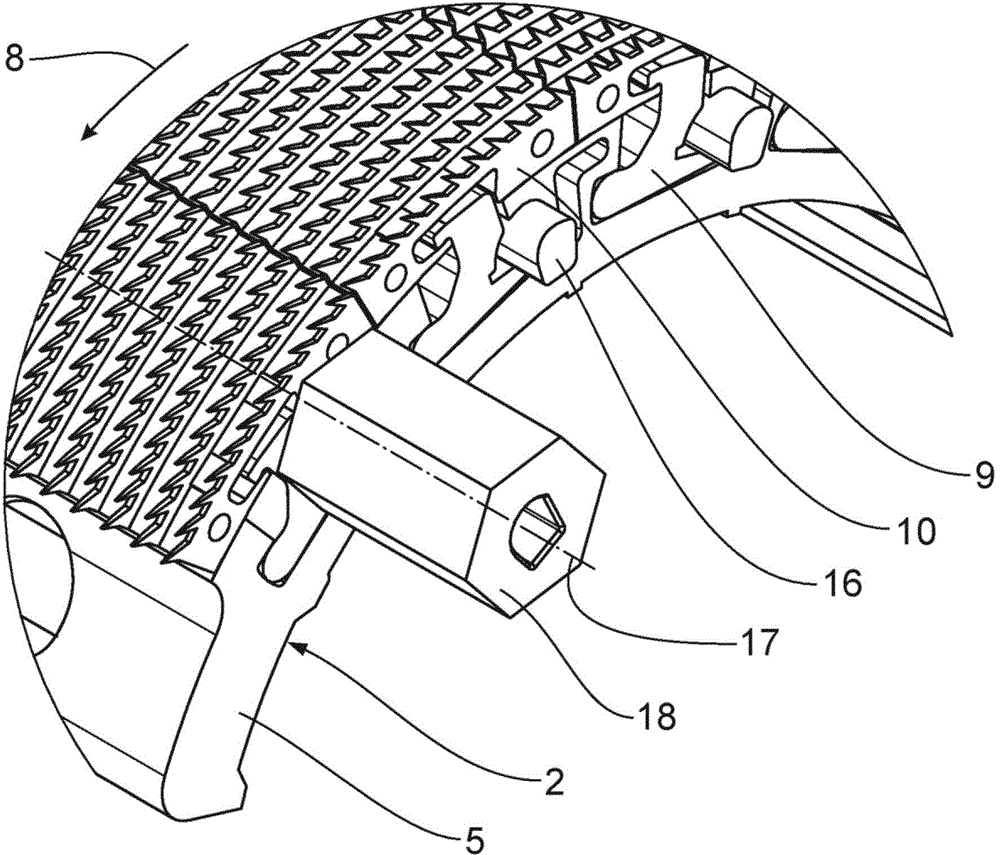

[0049] exist Figures 1 to 10 The parts corresponding to each other are provided with the same reference numerals. Details of the embodiments described in more detail below may represent the invention per se or may be part of the subject-matter of the invention.

[0050] figure 1 with 2 The illustrated carding element 7 comprises a substantially part-cylindrical base body 2 with a central longitudinal axis 3 , an outer surface / peripheral surface 4 and two end surfaces 5 . The outer surface 4 includes portions of the outer surface 52 which are here interrupted along the periphery of the outer surface 4 to form multiples / segments / parts. figure 1 The rear end face 5 shown in (relative to the central longitudinal axis 3 ) constitutes a stop wall.

[0051] according to figure 1 The carding element 7 has a carding area of 90°. The combing elements 7 can be fastened on a drum / drum not shown. To this end, a plurality of perforations 53 are provided. The combing elements 7 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com