Work machine peripheral monitoring device

A technology for working machines and monitoring devices is applied in the field of peripheral monitoring devices to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

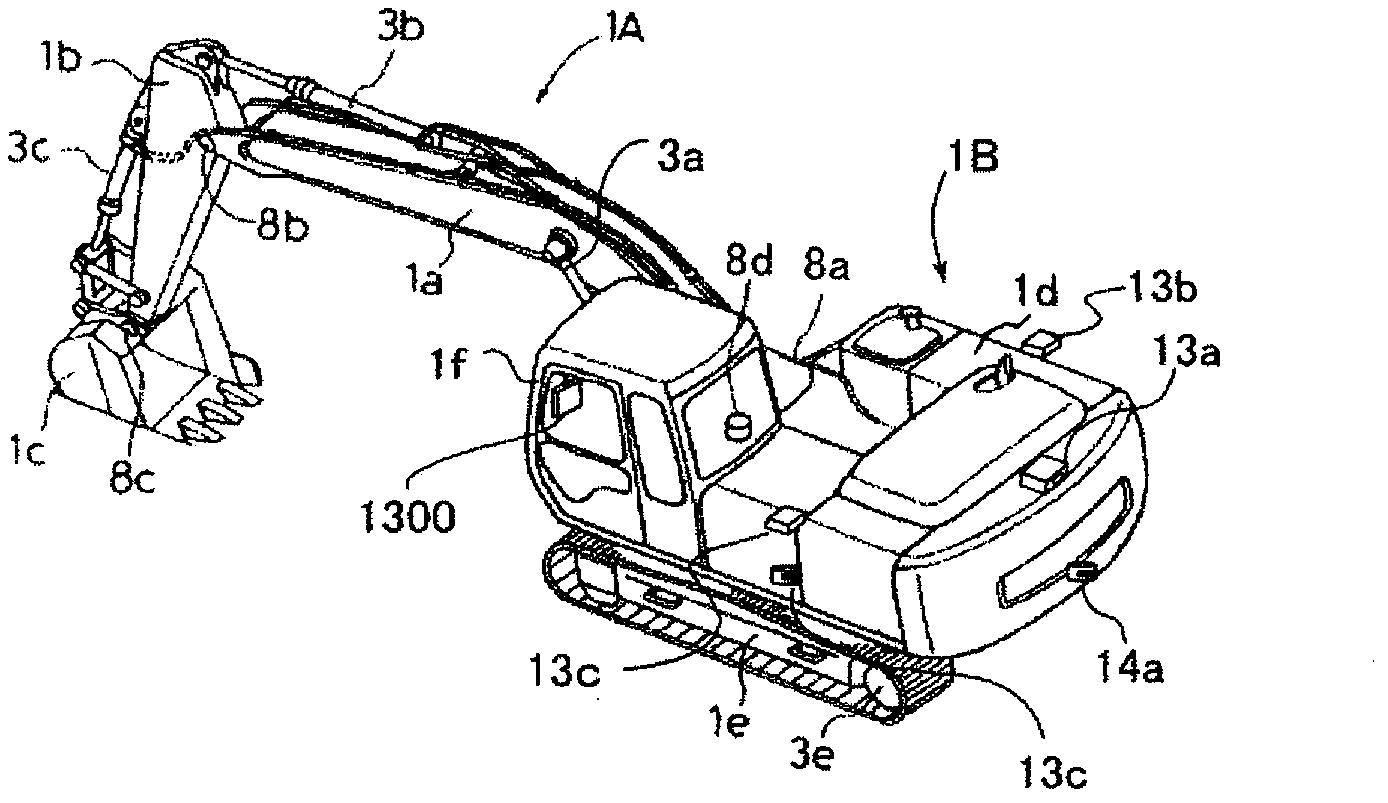

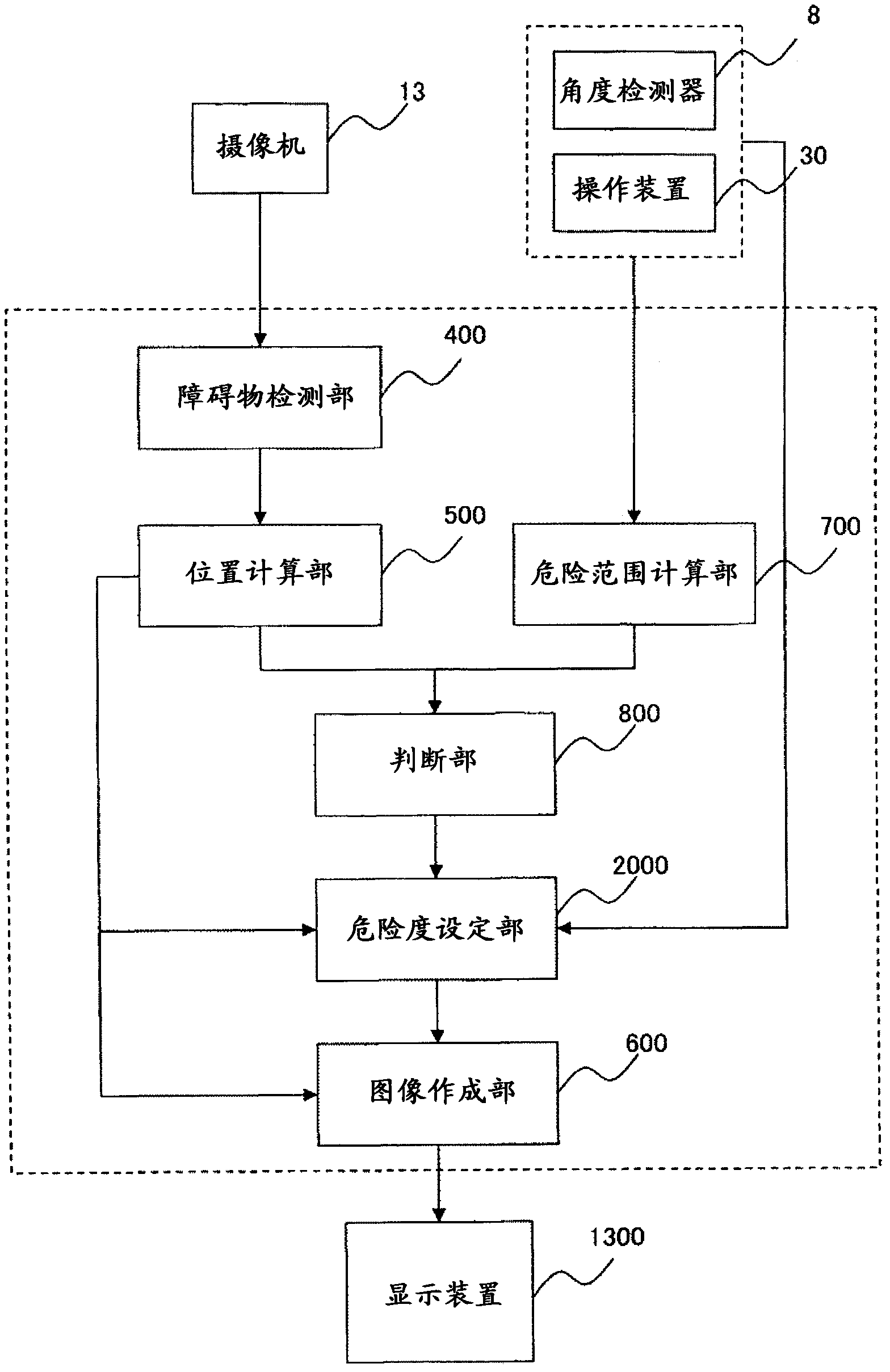

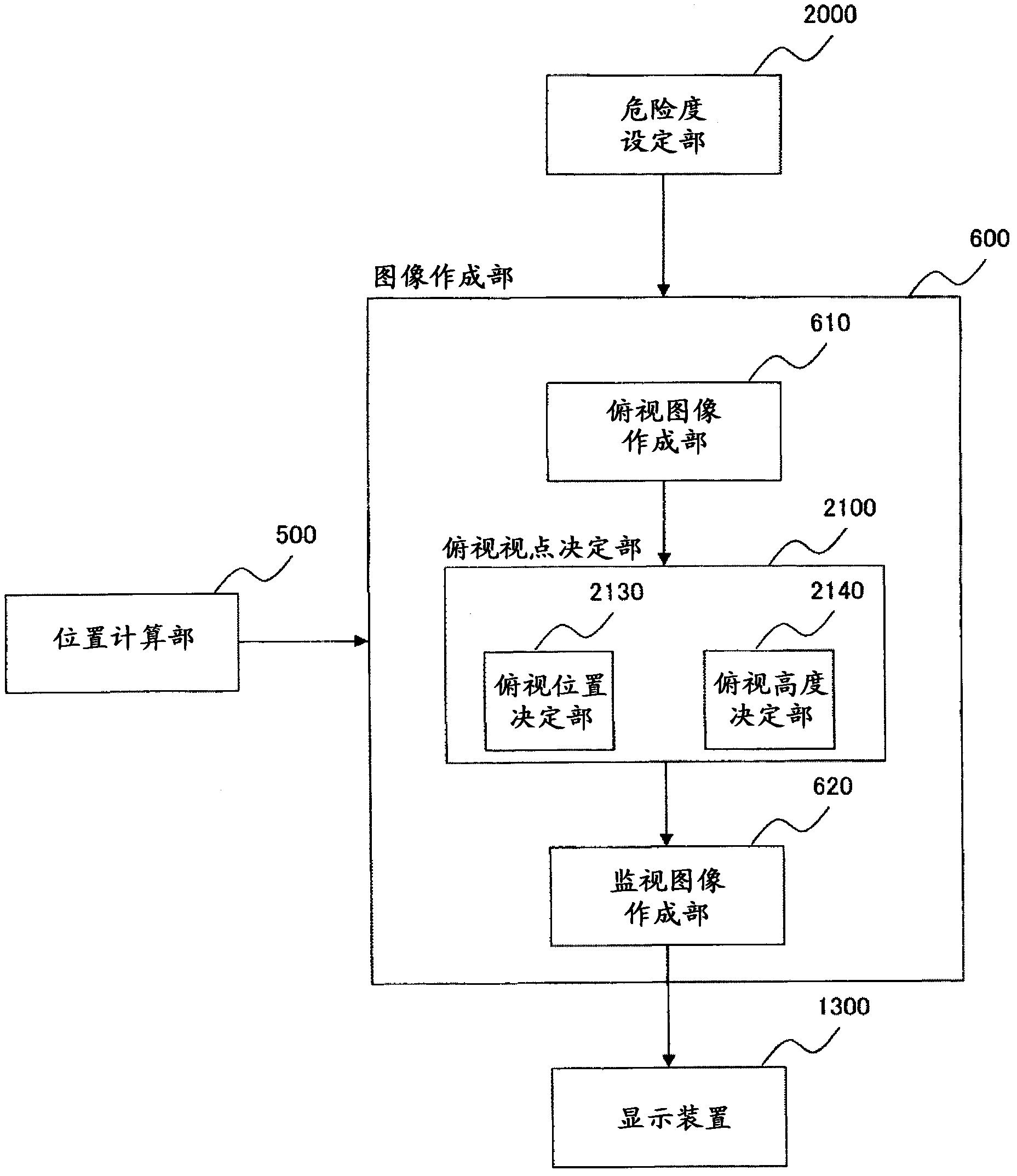

[0037] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is an external view of a hydraulic excavator as an example of the working machine according to the embodiment of the present invention. The hydraulic excavator shown in this figure has: a multi-joint type front working device 1A composed of a boom 1a, an arm 1b, and a bucket 1c that rotate in the vertical direction; an upper rotating body 1b and a lower traveling body 1e The vehicle body 1B constituted, and the display device 1300 installed in the cab 1f.

[0038] A cab 1f is provided on the upper revolving body 1d. The base end of the boom 1a of the front working device 1A is supported by the front portion of the upper swing body 1d. The boom 1a, the arm 1b, the bucket 1c, the upper swing body 1d, and the lower running body 1e pass through the boom cylinder 3a, the arm cylinder 3b, the bucket cylinder 3c, the swing motor (not shown) and the left and right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com