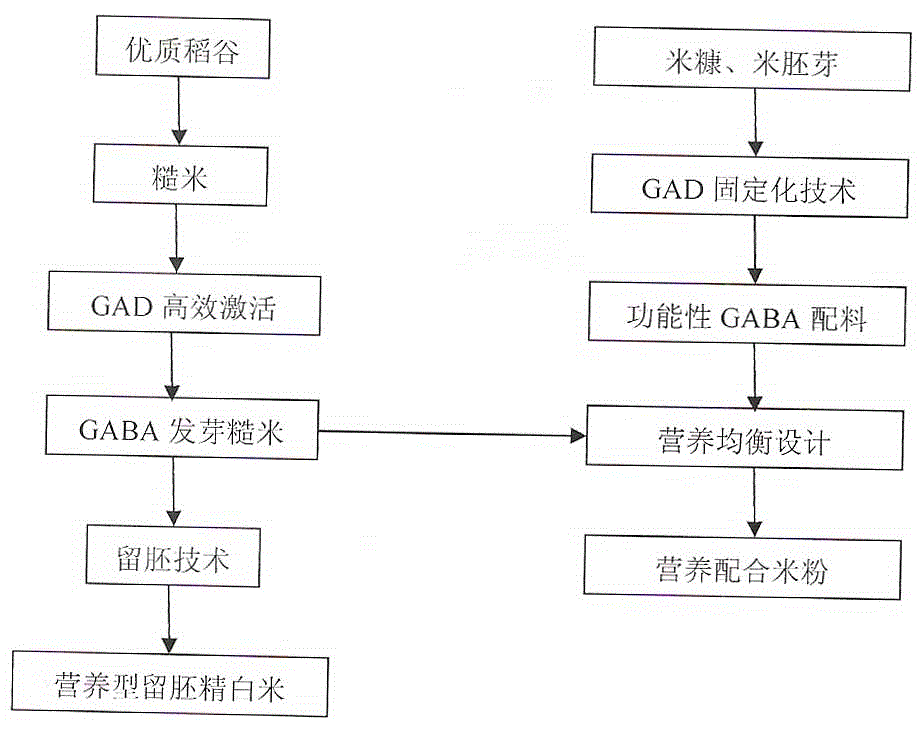

Method for producing food material with high GABA function with rice endogenous enzyme activation method

An endogenous, rice-based technology, applied in the fields of biochemical equipment and methods, food preparation, enzymes, etc., can solve the problems that are still in its infancy, and achieve the effect of improving brain function and liver function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of GABA (γ-aminobutyric acid): Weigh 200g of brown rice (brown rice is prepared by rice hulling and removing impurities) and put it in a shallow dish. Add 4 times the volume of water and soak at 25°C for 3h. Spread the soaked brown rice evenly in a shallow pan covered with four layers of gauze, add an appropriate amount of water, cover with wet gauze, germinate at 25°C for 24 hours and spray water regularly. Weigh 50g of germinated brown rice, add 200mL of water and grind it into a slurry with a high-speed tissue grinder, take a certain amount of brown rice pulp, add 8.0mmol / L substrate L-glutamic acid, 0.2mmol / L coenzyme PLP, 0.2 mmol / L Activator CaCl 2 , converted to GABA in PBS buffer with pH 6.1, and the conversion temperature was controlled at 37.5°C.

[0024] (2) GAD (glutamic acid decarboxylase) extraction: Weigh 100g of germinated brown rice, add 50mmol / L phosphate buffer (pH5.7), 0.5mmol / L vitamin B 6 , 2mmol / L EDTA, 0.2% β-mercaptoethanol, ...

Embodiment 2

[0027] (1) Preparation of GABA (γ-aminobutyric acid): Weigh 200g of brown rice (brown rice is prepared by rice hulling and removing impurities) and put it in a shallow dish. Add 4 times the volume of water and soak at 30°C for 6h. Spread the soaked brown rice evenly in a shallow pan covered with four layers of gauze, add an appropriate amount of water, cover with wet gauze, germinate at 30°C for 36 hours and spray water regularly. Weigh 50g of germinated brown rice, add 200mL of water and grind it into a slurry with a high-speed tissue grinder, take a certain amount of brown rice pulp, add 8.5mmol / L substrate sodium glutamate, coenzyme PLP, 0.2mmol / L activator CaCl 2 , converted into GABA in PBS buffer solution with pH 6.2, and the conversion temperature was controlled at 38.0°C.

[0028] (2) GAD (glutamic acid decarboxylase) extraction: Weigh 200g of brown rice, add 800ml of extraction solution (50mmol / L potassium phosphate buffer, pH5.6, 2mmol / L mercaptoethanol, 2mmol / L E...

Embodiment 3

[0031] (1) Preparation of GABA (γ-aminobutyric acid): Weigh 200g of brown rice (brown rice is prepared by rice hulling and removing impurities) and put it in a shallow dish. Add 4 times the volume of water and soak at 35°C for 9h. Spread the soaked brown rice evenly in a shallow pan covered with four layers of gauze, add an appropriate amount of water, cover with wet gauze, germinate at 30°C for 46 hours and spray water regularly. Weigh 50g of germinated brown rice, add 200mL of water and grind it into a slurry with a high-speed tissue grinder, take a certain amount of brown rice pulp, add 9.0mmol / L substrate sodium glutamate, coenzyme PLP, 0.2mmol / L activator CaCl 2 , at pH 6.3 in PBS buffer (containing 50mmol / L phosphate buffer (pH5.7), 0.2mmol / L pyridoxal phosphate (PLP), 2mmol / L EDTA, 0.2% β-mercaptoethanol, 0.15mol / L NaCl) to generate GABA, and control the conversion temperature to 38.5°C.

[0032] (2) GAD (glutamic acid decarboxylase) extraction: Weigh 100g of germi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com