On-line continuous degassing device

A degassing device and line technology, which is applied in the field of material mixing and discrete devices, can solve the problems of low production capacity, secondary pollution of raw materials, waste of raw materials, etc., and achieve the effects of simple structure, good degassing effect and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

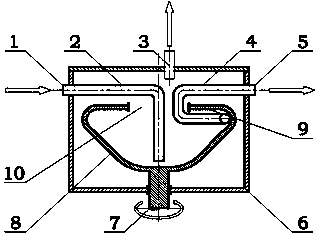

[0011] Examples of the present invention figure 1 As shown: the feed pipe 2 and the discharge pipe 4 are fixed on the vacuum chamber 6, and extend into the cup holder 8 through the cover hole 10; the vacuum chamber 6 is connected with the transmission shaft 7 through a sealing gasket, and the transmission shaft 7 extends into the vacuum The cup holder 8 in the cavity 6 is locked on the transmission spindle 7; the transmission spindle 7 attaches the rotation transmitted by the motor to the cup holder 8, so that the raw materials flow into the cup holder 8 continuously through the feed interface 1 through the feed pipe 2 At the bottom position of the center, the raw material continuously slides upward after obtaining enough kinetic energy from the cup holder 8, and continuously separates the bubble phase inside the raw material during the sliding process, and discharges the bubble phase from the gas phase discharge pipe 3; the discharge pipe 4 Extend from the middle of the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com