Vacuum partition scraper type continuous defoaming machine

A scraper type, defoaming machine technology, applied in the direction of foam dispersion/prevention, can solve the problems of missing raw material temperature control, raw material waste, secondary pollution of raw materials, etc., to achieve high defoaming treatment efficiency, good defoaming effect, reduce The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

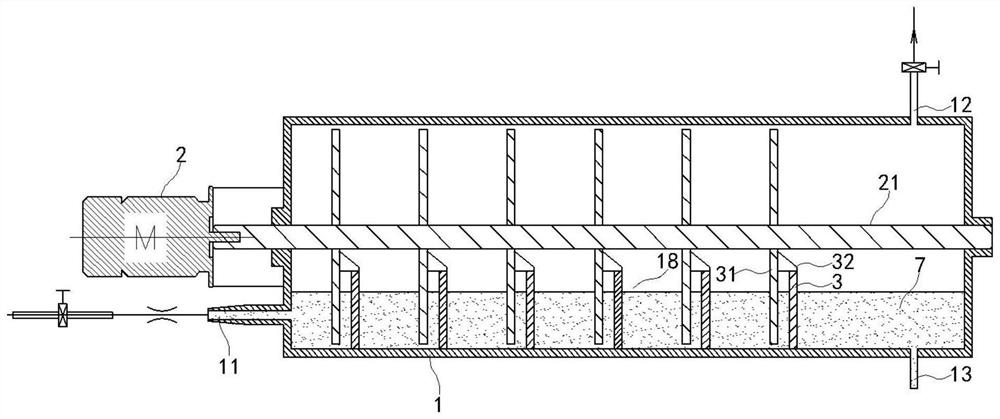

[0058] Such as figure 1 As shown, a vacuum partition scraper type continuous degassing machine of the present embodiment comprises a horizontally arranged cylindrical separation tank 1, and the separation tank 1 is provided with a feed pipe 11, a vacuum pipe 12 and a discharge port 13; the end of the separation tank 1 The motor 2 drives the main shaft 21 coaxial with the separation tank 1 in the separation tank 1 to rotate; the five baffles 3 arranged at the bottom of the separation tank 1 divide the lower part of the separation tank 1 into six slurry chambers 18, and the feed pipe 11 It communicates with the first slurry chamber 18, and the discharge port 13 is located at the last slurry chamber 18; it is fixed on the main shaft 21 and does not contact the inner wall of the separation tank 1 with 5 belt trays 31, and the belt trays 31 are located at There is a discharge gap between the feed end side of the baffle 3 and the baffle 3 ; the slurry scraper 32 is arranged above t...

Embodiment 2

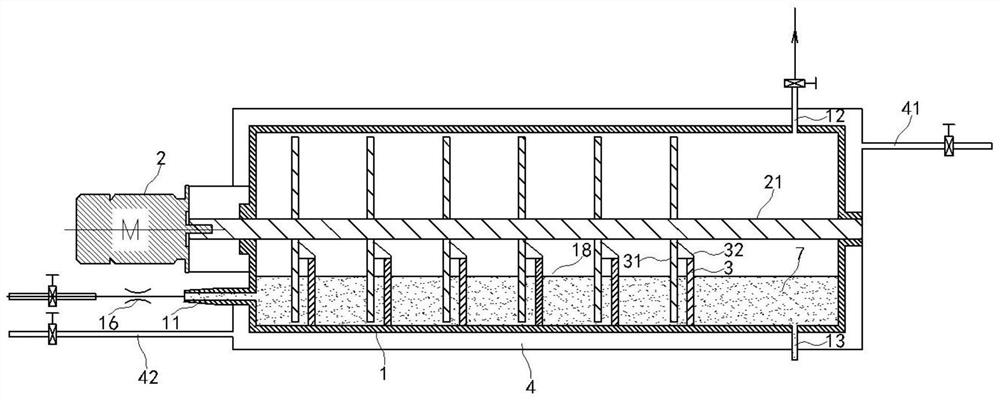

[0062] Such as figure 2 As shown, this embodiment is a further optimization of Embodiment 1. The outer surface of the separation tank 1 is provided with a cooling and heating medium circulation chamber 4, and the cooling and heating medium circulation chamber 4 is provided with a cooling and heating medium inlet 42 or a cooling and heating medium outlet 41. A cold and hot medium outlet 41 or a cold and hot medium inlet 42 are arranged below the medium circulation chamber 4, and the temperature in the separation tank 1 can be adjusted by feeding the refrigerant or heat medium, so that the separation tank 1 is always in the process temperature range for the degassing of the slurry 7, which is more It is beneficial to the defoaming of the slurry 7.

Embodiment 3

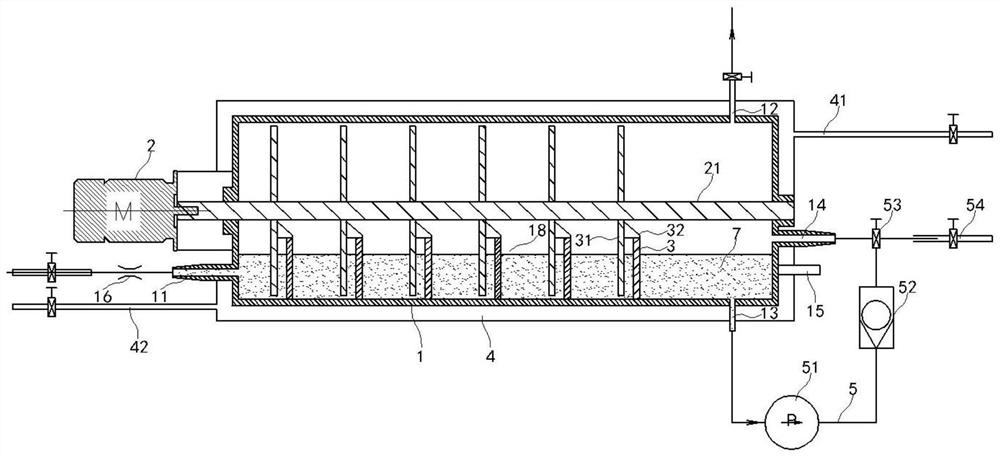

[0064] Such as image 3 As shown, this embodiment is a further optimization of Embodiment 1. The outer surface of the separation tank 1 is provided with a cooling and heating medium circulation chamber 4, and the cooling and heating medium circulation chamber 4 is provided with a cooling and heating medium inlet 42 or a cooling and heating medium outlet 41. A cold and hot medium outlet 41 or a cold and hot medium inlet 42 are arranged below the medium circulation chamber 4, and the temperature in the separation tank 1 can be adjusted by feeding the refrigerant or heat medium, so that the separation tank 1 is always in the process temperature range for the degassing of the slurry 7, which is more Facilitate the defoaming of slurry 7;

[0065] The discharge port 13 is connected to the one-way valve 52 through the discharge pipe 5 and the discharge pump 51, and the one-way valve 52 is connected to the three-way valve 53, and one end of the three-way valve 53 is connected to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com