Solid wood composite non-painted door

A solid wood composite, paint-free door technology, applied in the door leaf and other directions, can solve problems such as deformation, and achieve the effects of exquisite craftsmanship, ingenious structural design, and firm installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

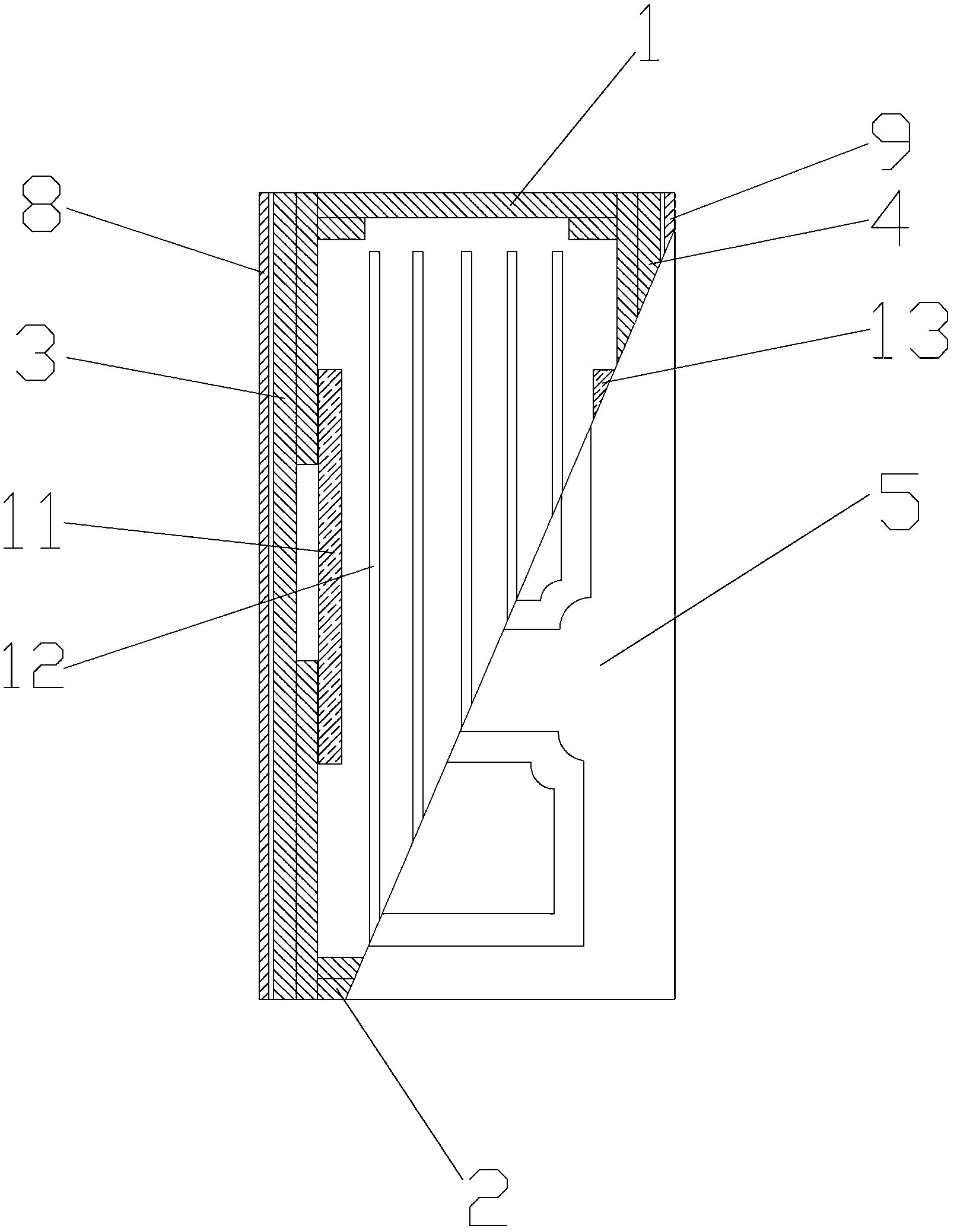

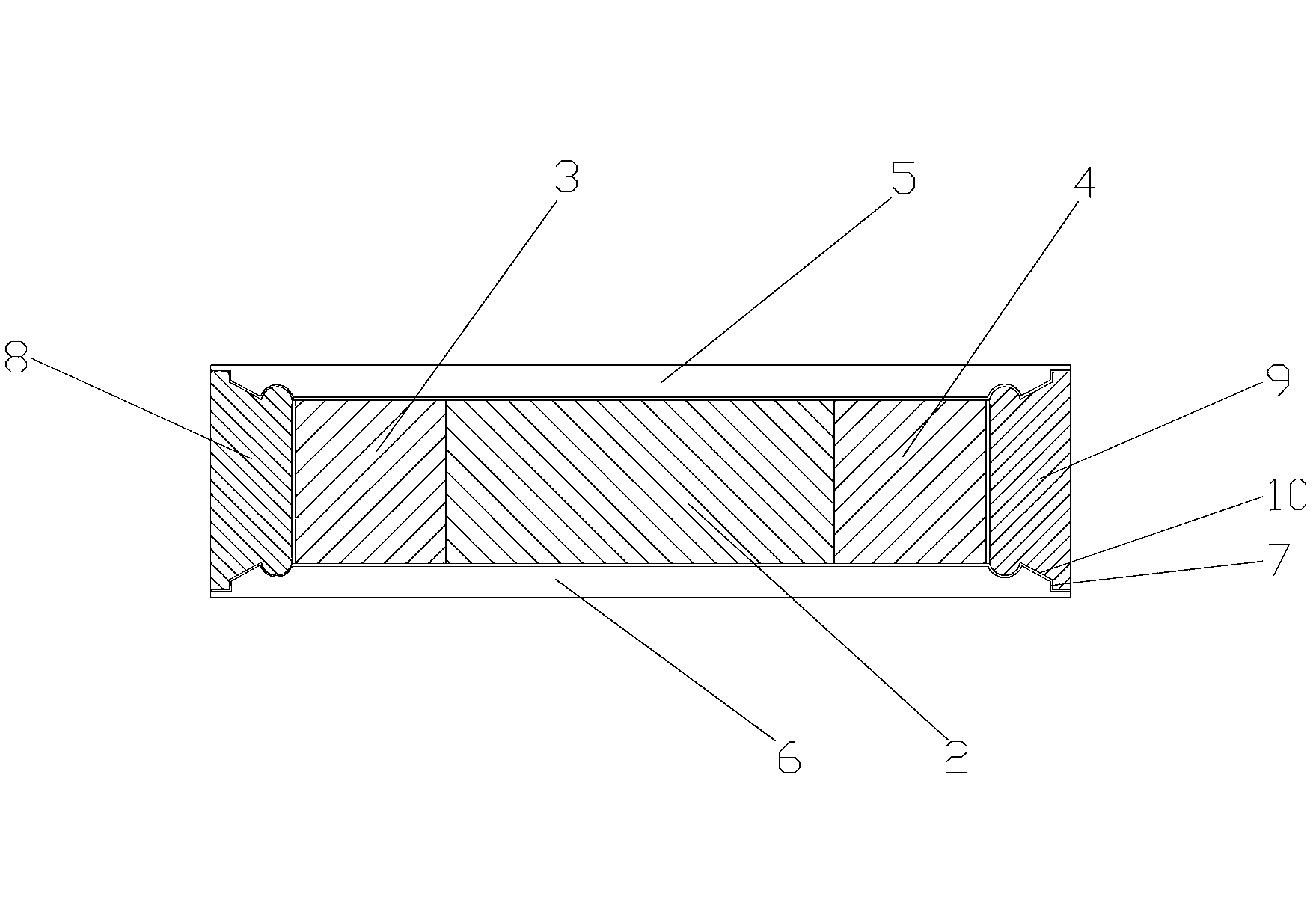

[0015] A solid wood composite paint-free door, comprising a door frame, a door panel assembly and an edge banding assembly, the door frame includes an upper door frame 1, a lower door frame 2, a left door frame 3 and a right door frame 4, and the upper door frame 1 and the lower door frame 2 are respectively located at the door of the door. The upper and lower ends are arranged horizontally, and the left door frame 3 and the right door frame 4 are arranged vertically on the left and right sides of the door respectively. The upper door frame 1, the lower door frame 2, the left door frame 3 and the right door frame 4 are fixedly connected by milk white glue. The assembly includes a front door panel 5 and a rear door panel 6, and first dovetails are respectively opened on the left and right sides of the front door panel 5 and the rear door panel 6.

[0016] Side 7, after the front door panel 5 and the rear door panel 6 are polished, they are evenly distributed on the surfaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com