Mechanical seal structure of radial split groove end face with imitation bird wing fin groove

A kind of end face mechanical seal and mechanical seal technology, which is applied in the direction of engine seal, mechanical equipment, engine components, etc., can solve the problems that it is difficult to meet the operation requirements of mechanical seal, the opening ability of the end face cannot be adapted, and the dry gas seal is difficult to open quickly, etc., to achieve Large bearing capacity, atmospheric film stiffness, easy to open effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

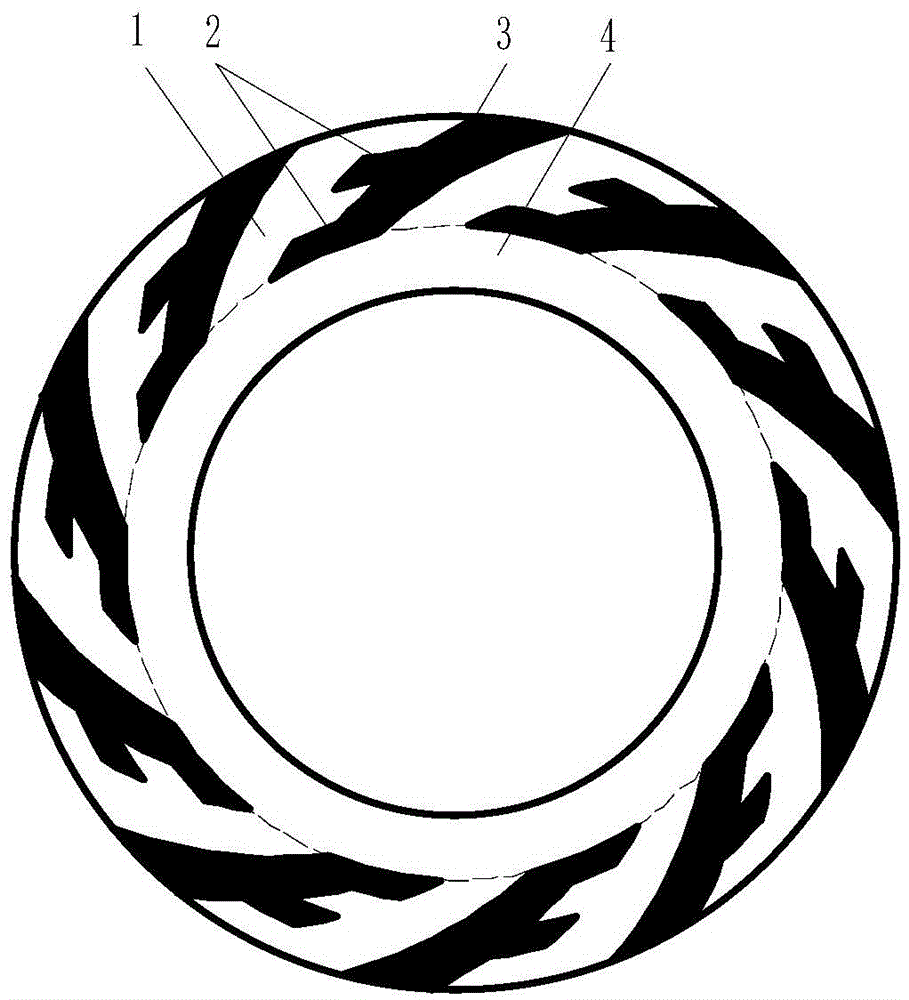

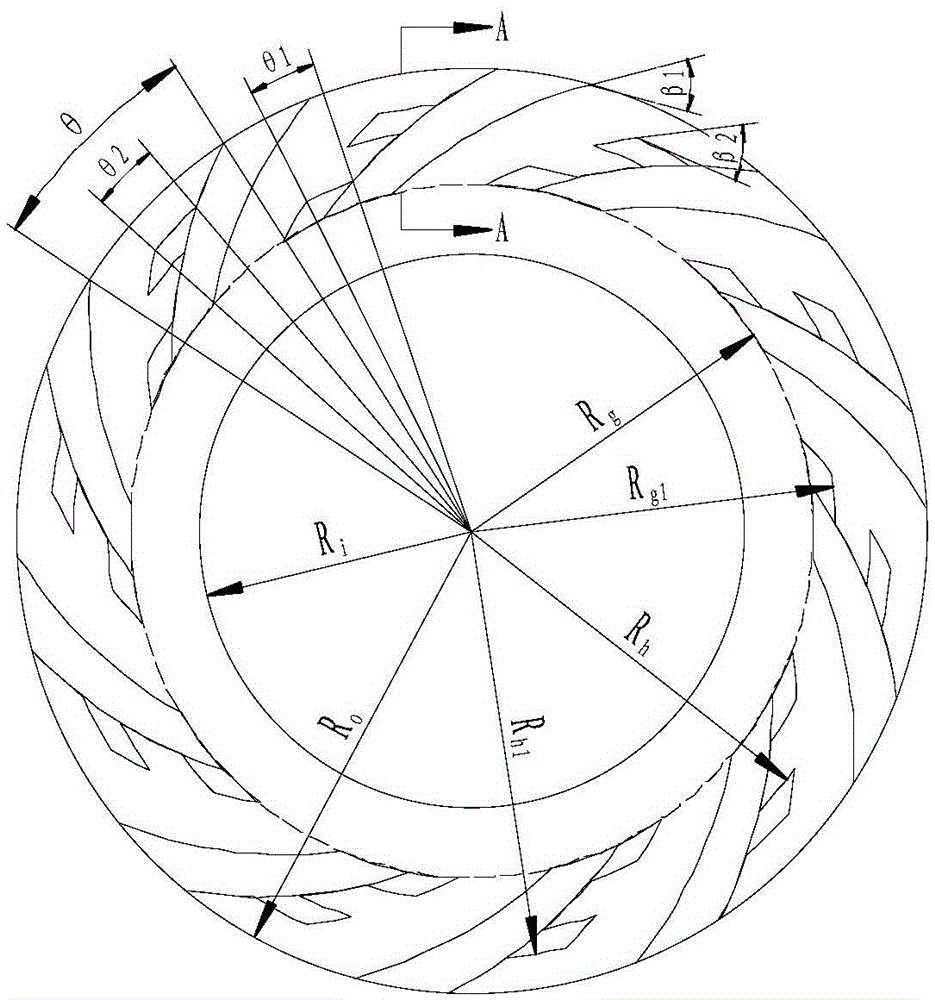

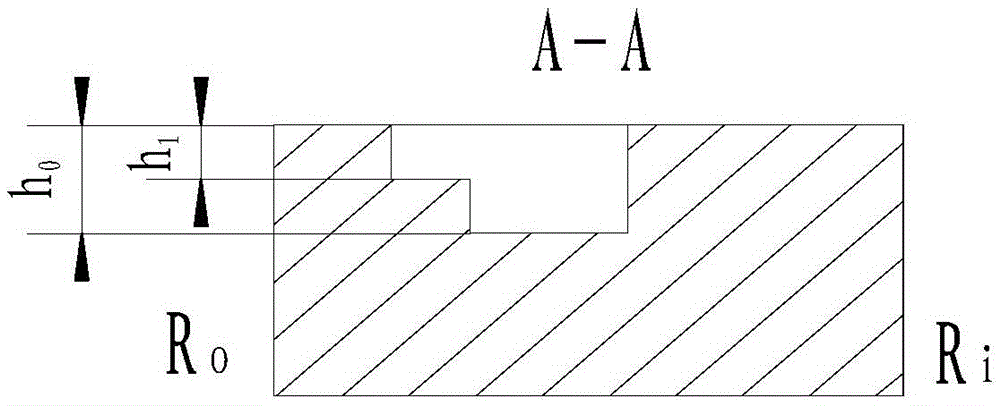

[0028] refer to figure 1 , figure 2 and image 3 , a radial split type groove end face mechanical seal structure imitating a bird wing groove, including two mechanical seal rings, namely a moving ring and a static ring, at least one mechanical seal ring in the moving ring or static ring is provided with a There are a plurality of radial diversion grooves imitating bird wing grooves distributed along the circumference of the sealing end surface. The radial diversion grooves imitating bird wing grooves are located on the high pressure side of the medium, namely upstream. The diversion groove includes a diversion groove 3 and more than two diversion grooves 2 with a structure similar to a bird's wing groove. extend. The ungrooved area between the radial diversion grooves imitating bird wing grooves is a sealing weir, and the annular zone formed by the ungrooved area in the circumferential direction of the end surface is a sealing dam, and the sealing dam is located on the low...

Embodiment 2

[0037] refer to Figure 4 , The difference between this embodiment and Embodiment 1 is that the shape of the shunt can be a triangle, a quadrilateral, a rhombus, or a trapezoid with a straight line, an arc line, or a spiral line on the side wall. One is the same.

Embodiment 3

[0039] refer to Figure 5 , the difference between this embodiment and the first embodiment lies in the ratio w of the circumferential arc length of the shunt groove 2 to the circumferential arc length of the sealing weir 1 corresponding to the drainage groove 3 1 / w=1, that is, the splitter groove 2 is a circumferential ring groove, and the rest of the structure and implementation are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com