Vertically-partitioned metallized grid safe film electrode structure

An electrode structure and metallization technology, applied in the direction of fixed capacitor electrodes, fixed capacitor components, etc., can solve the problems of reduced dielectric withstand voltage, inability to increase width, voltage breakdown, etc., to increase service life and reduce capacity loss. , reduce the effect of additional heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

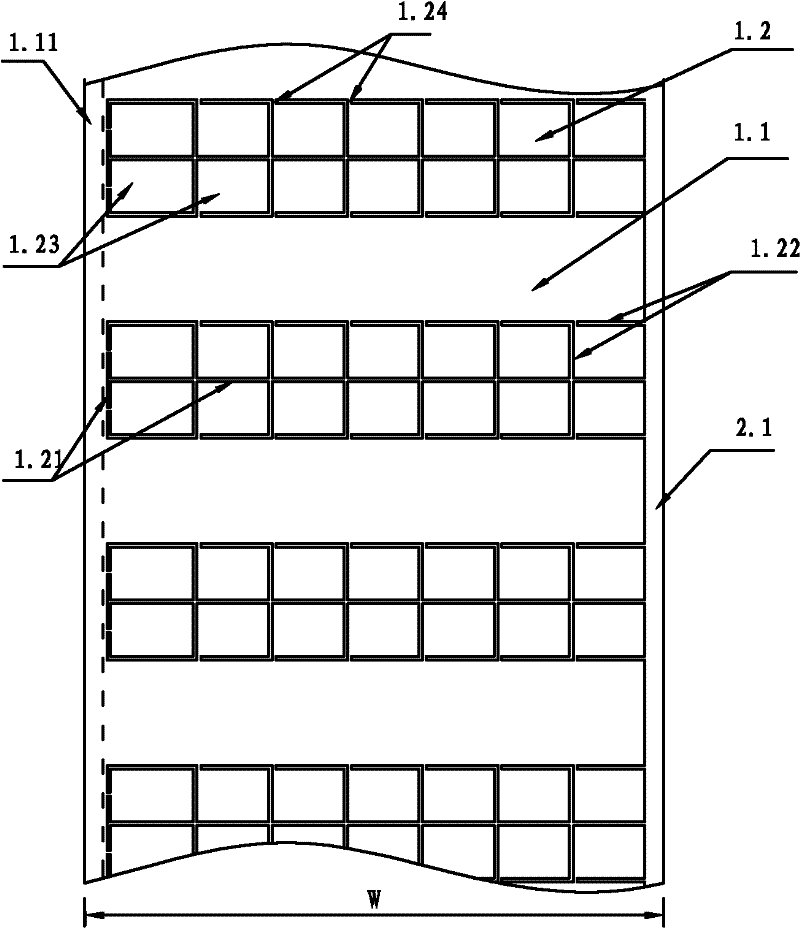

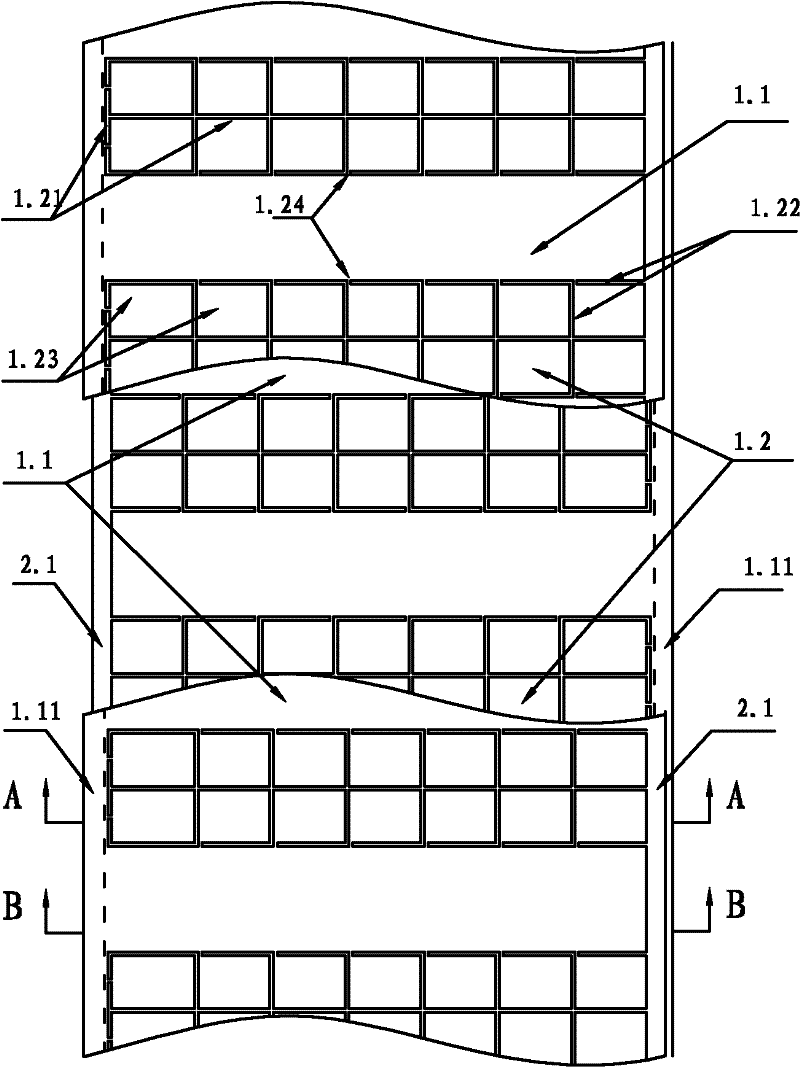

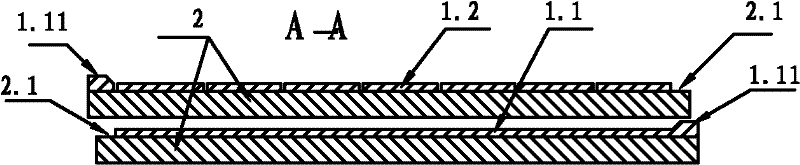

[0034] Such as figure 1 , image 3 As shown, a vertically partitioned metallized grid-type safety film electrode structure has an upper and lower metallized safety film, and each layer of metallized safety film is a composite film formed by plating a metal electrode coating on the dielectric base film 2. The one side parallel to the longitudinal direction of the film is an uncoated edge 2.1, and the other side parallel to the longitudinal direction is a thickened edge 1.11 of the coating, and the coating between the edge 2.1 and the thickened edge 1.11 is composed of a continuous coating area 1.1 and a mesh in the longitudinal direction. The lattice pattern areas 1.2 are distributed alternately at intervals, and the longitudinal widths of these two areas are approximately equal, and the longitudinal width of the continuous coating area 1.1 can be slightly shorter than that of the grid pattern area 1.2 by 1-3 mm.

[0035] The coating in the above-mentioned grid pattern area 1...

Embodiment 2

[0040] The lateral side lengths of the small electrode blocks 1.23 in the grid pattern area 1.2 can be distributed unequally, such as Figure 5 As shown, the closer to the continuous plating thickening edge 1.11, the larger the area of the small electrode piece is, so that the small electrode piece with a short current path has a larger area, and the small electrode piece with a long current path has a smaller area, and the narrow strip of coating 1.24 It is also set according to the principle that the current path and the thickened side are close to each other, which is conducive to further reducing AC and high-frequency losses.

Embodiment 3

[0042] Electrode small blocks can be designed into a variety of polygonal small block electrode unit shapes, for example, such as Image 6 As shown, the coating in the grid pattern area 1.2 is divided into two rows of small strips by T-shaped space strips 1.21, and then they are separated into multiple columns of parallelogram electrode small pieces 1.23 with a plurality of oblique space strips 1.22, such as rhombus (The electrode small pieces on both sides are trapezoidal), each oblique space bar is all intersected with the T-shaped space bar, and each electrode small piece has an independent coating narrow strip 1.24 that acts as a miniature fuse and adjacent The continuous coating area 1.1 or the thickened side 1.11 of the coating are connected, and the narrow strip 1.24 of the coating is also set according to the principle that the current path is close to the thickened side, which is beneficial to the flow path and direction of the edge current in the small electrode block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com