Stress relieving blasting method for side wall rock pillar type rock burst of two synchronously tunneling deeply-buried tunnels

A technology of stress relief and rockburst, applied in blasting and other directions, to improve construction safety, shorten construction period, and ensure the progress of tunneling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention adopts a series of orderly working methods such as drilling, rationally arranging blasting holes and their directions, and controlling the detonation sequence in the stress concentration area of the deep-buried tunnel to change the properties of the side wall rock mass to achieve the effect of eliminating or reducing the degree of energy accumulation , to achieve the purpose of controlling rockburst by eliminating or reducing the rockburst energy of the side wall.

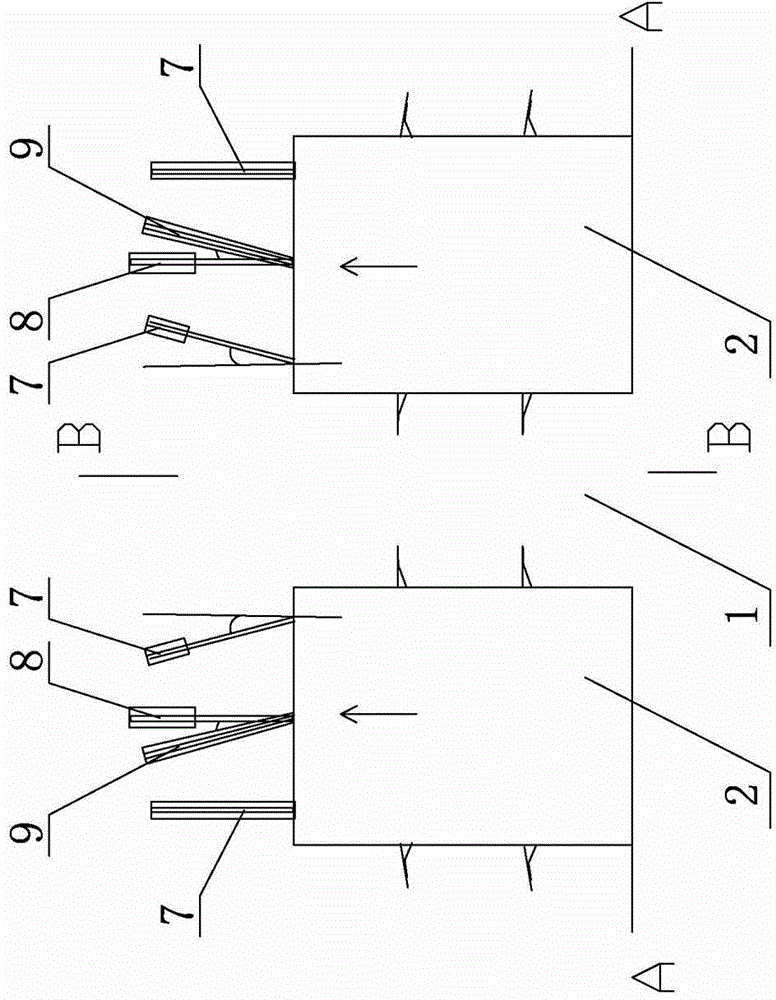

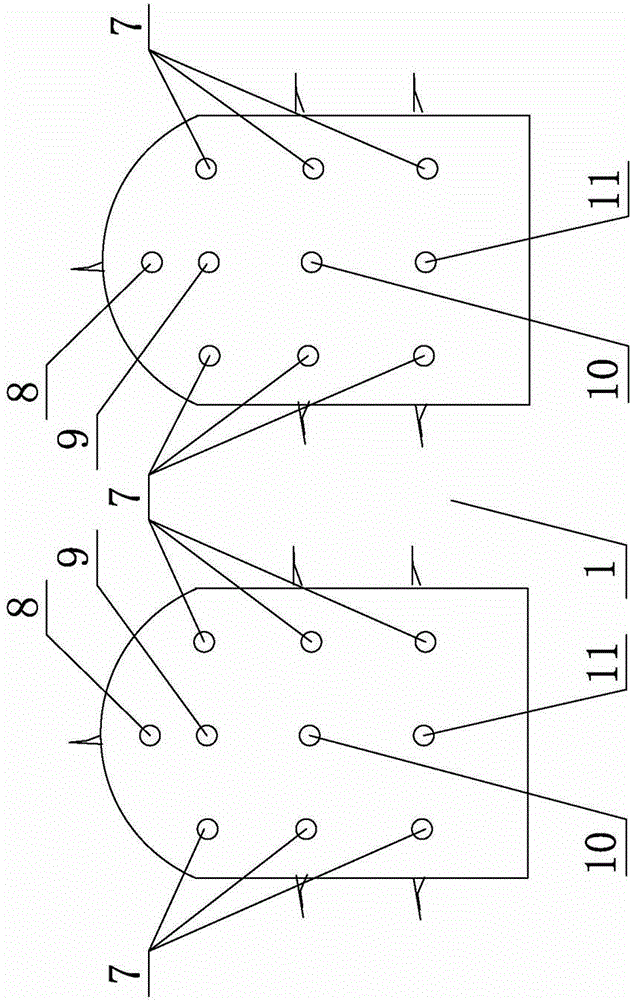

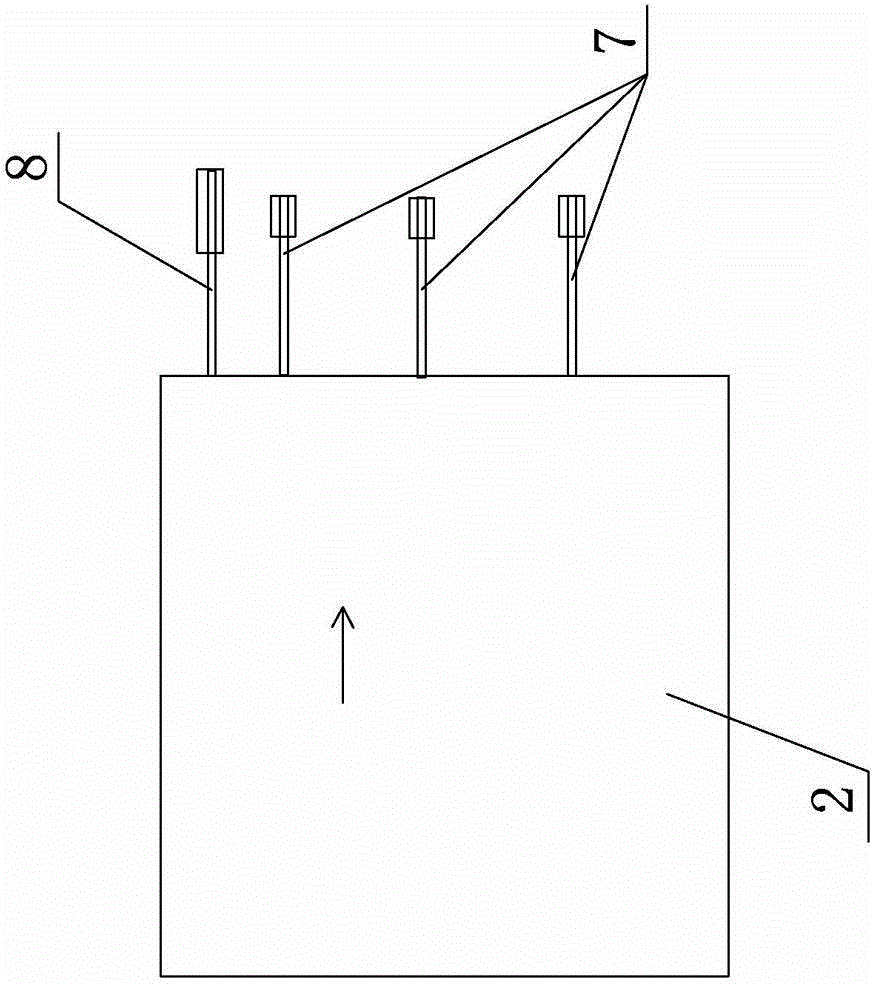

[0019] Such as Figure 1-Figure 3 As shown, the simultaneous excavation of two tunnels is taken as an example, and the specific scheme is as follows:

[0020] a. Drill a group of blast holes on the excavation faces of the caverns 2 on both sides of the side wall rock pillar 1, and ensure that the two groups of blast holes are arranged symmetrically with the vertical axis of the rock pillar 1 as the central axis; 10 blast holes are drilled on the excavation face. Each blasting hole i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com