Double-layer contemporarily excavated in same direction deep-buried-tunnel rock burst removing structure and application thereof

A tunnel and double-layer technology, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems of large manpower, financial resources and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

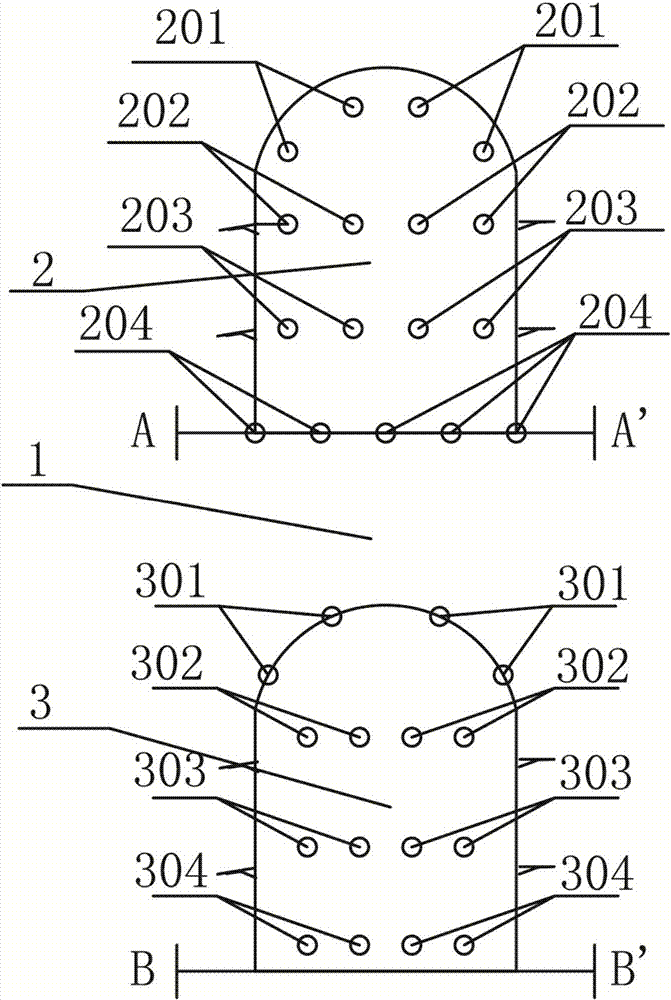

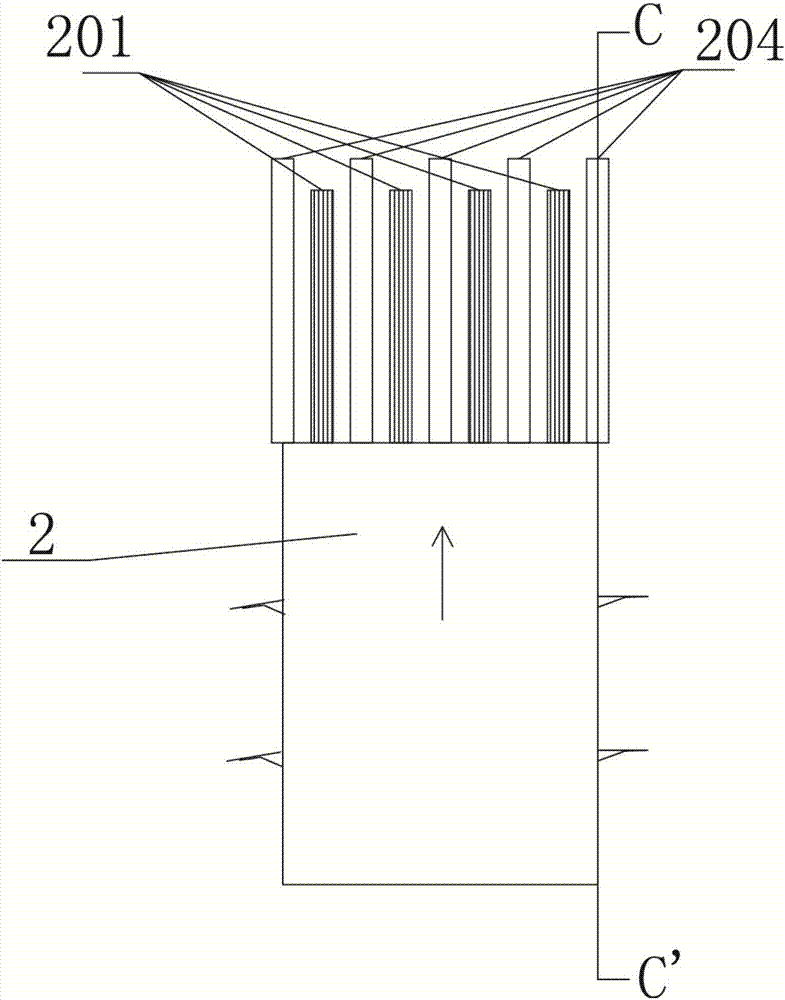

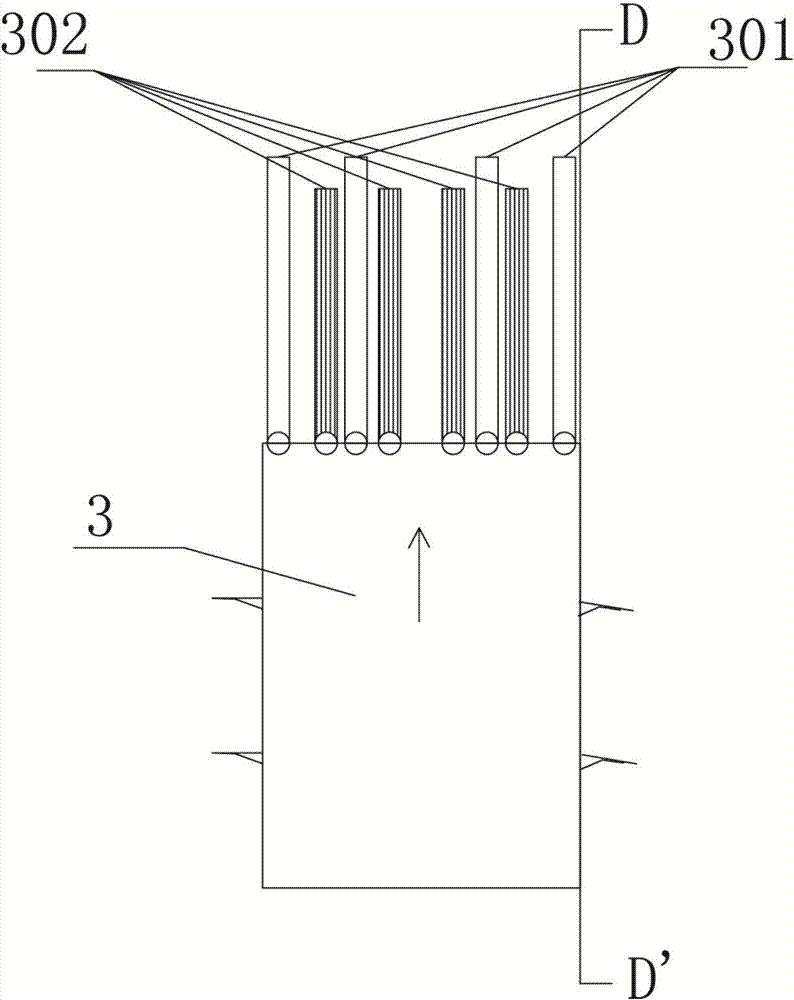

[0027] Several groups of blast holes and control holes are respectively drilled on the excavation faces of the upper and lower chambers 2 and 3 of the rock mass 1 between the upper and lower chambers. 12 blast holes and 4 control holes are drilled on the excavation face of each chamber. All blasting holes and control holes are arranged in the stress concentration area, and the principle of hole depth is to reach or pass through the stress concentration area; the number of blasting holes, the size of the hole and the amount of charge are to weaken the rock mass to the greatest extent and not cause excessive damage to the rock mass. The increase in support workload is the principle, and at the same time, the potential rockburst strength and the effectiveness of on-site support need to be considered.

[0028] In the upper chamber 2, along the axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com