Treatment system for concentration tank of iron ore concentrates

A processing system and concentration tank technology, which is applied to the feeding/discharging device of the sedimentation tank, the sedimentation tank, etc., can solve the problems of excessive solid particle content in the lower ore and insufficient processing capacity of the concentration tank, so as to improve the processing capacity, The effect of reducing the solids content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

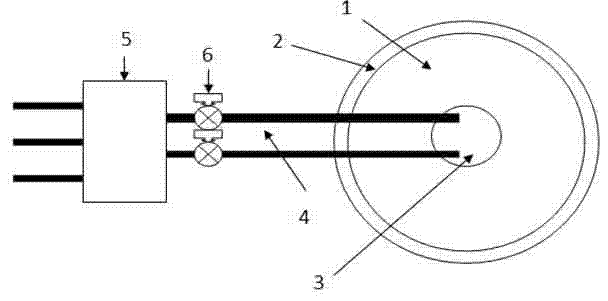

[0018] Combine below figure 2 , the present invention is further described:

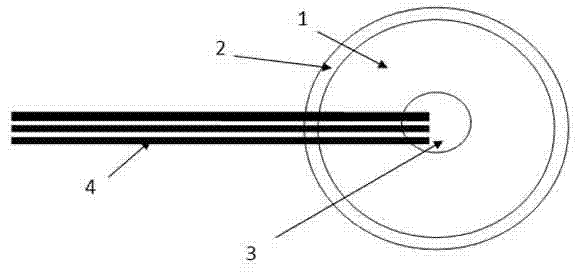

[0019] An iron concentrate concentration pool treatment system, comprising a concentration pool 1, a concentration pool overflow tank 2, a central distribution barrel 3, and a concentrate pipeline 4, the output of the concentrate pipeline 4 is connected to the central distribution barrel 3, and the center distribution barrel 3 is outside Concentration pool 1, the outside of the concentration pool 1 is the concentration pool overflow tank 2, the concentrate pipeline 4 is composed of a plurality of concentrate fine pipes and a plurality of concentrate thick pipes, and a plurality of concentrate fine pipes and a plurality of concentrate thick pipes Connected through the ore distribution box 5, the number of concentrate fine pipes is more than the number of concentrate thick pipes, one end of the concentrate thick pipe is connected to the central distribution barrel 3, and the other end of the concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com