Consumable-free particle specified flue gas solid particle treatment equipment

A solid particle and processing equipment technology, applied in the direction of dispersed particle separation, separation methods, chemical instruments and methods, etc., can solve the problems of large amount of remaining fixed particles in flue gas, poor treatment effect, large consumption of consumables, etc., and achieve solid particle content Low, thorough airflow treatment, and the effect of increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of this embodiment will be described below in conjunction with the accompanying drawings.

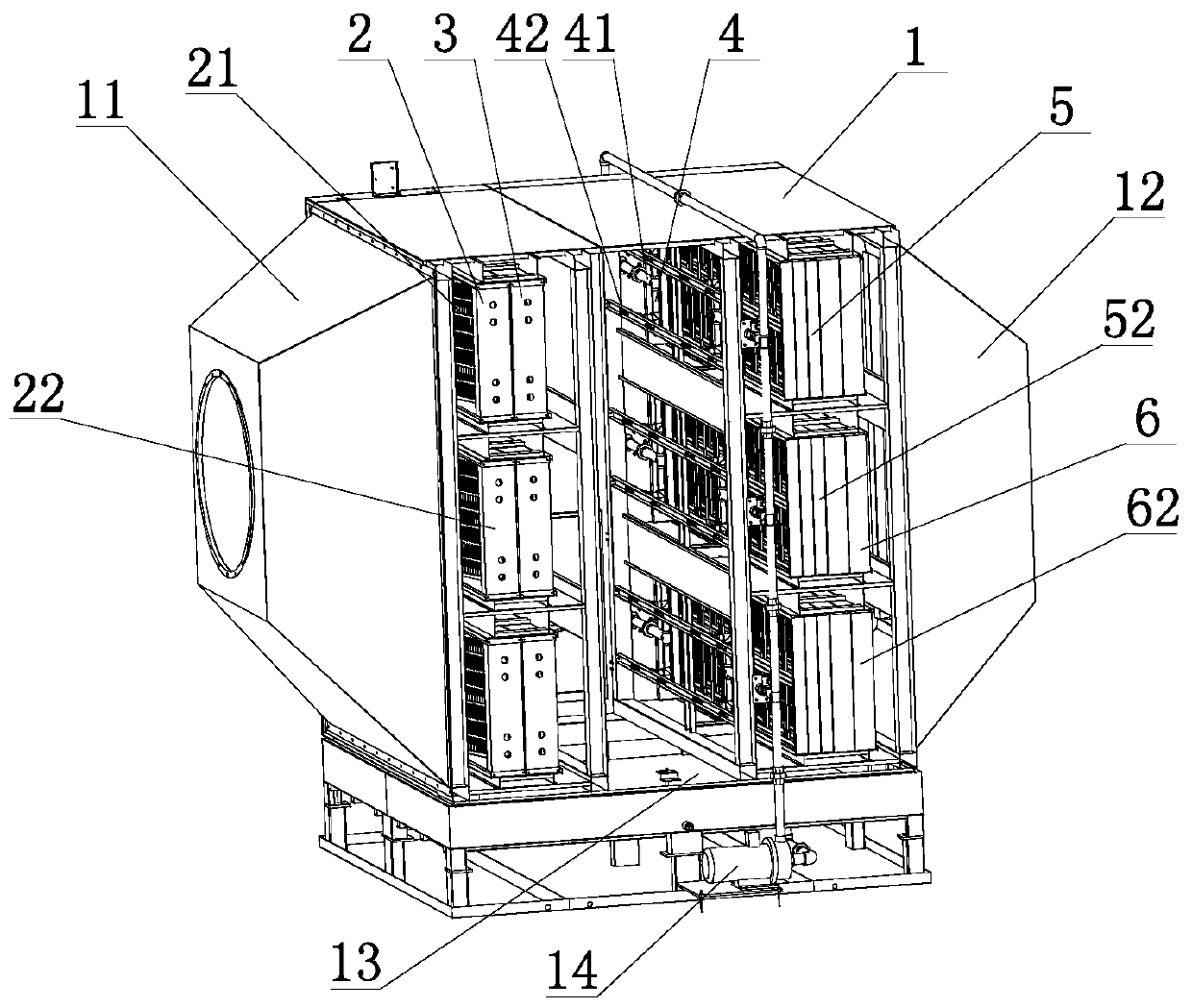

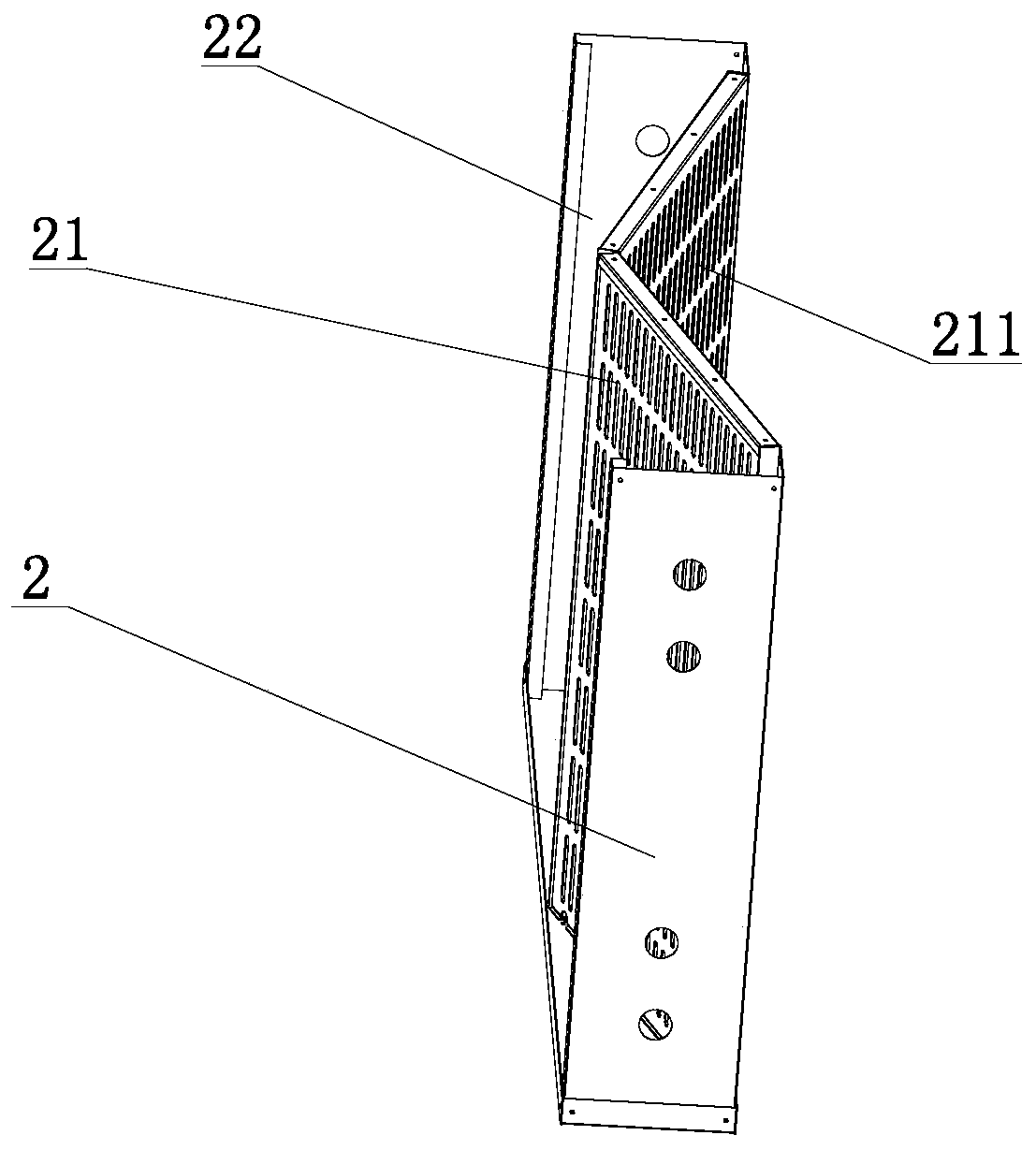

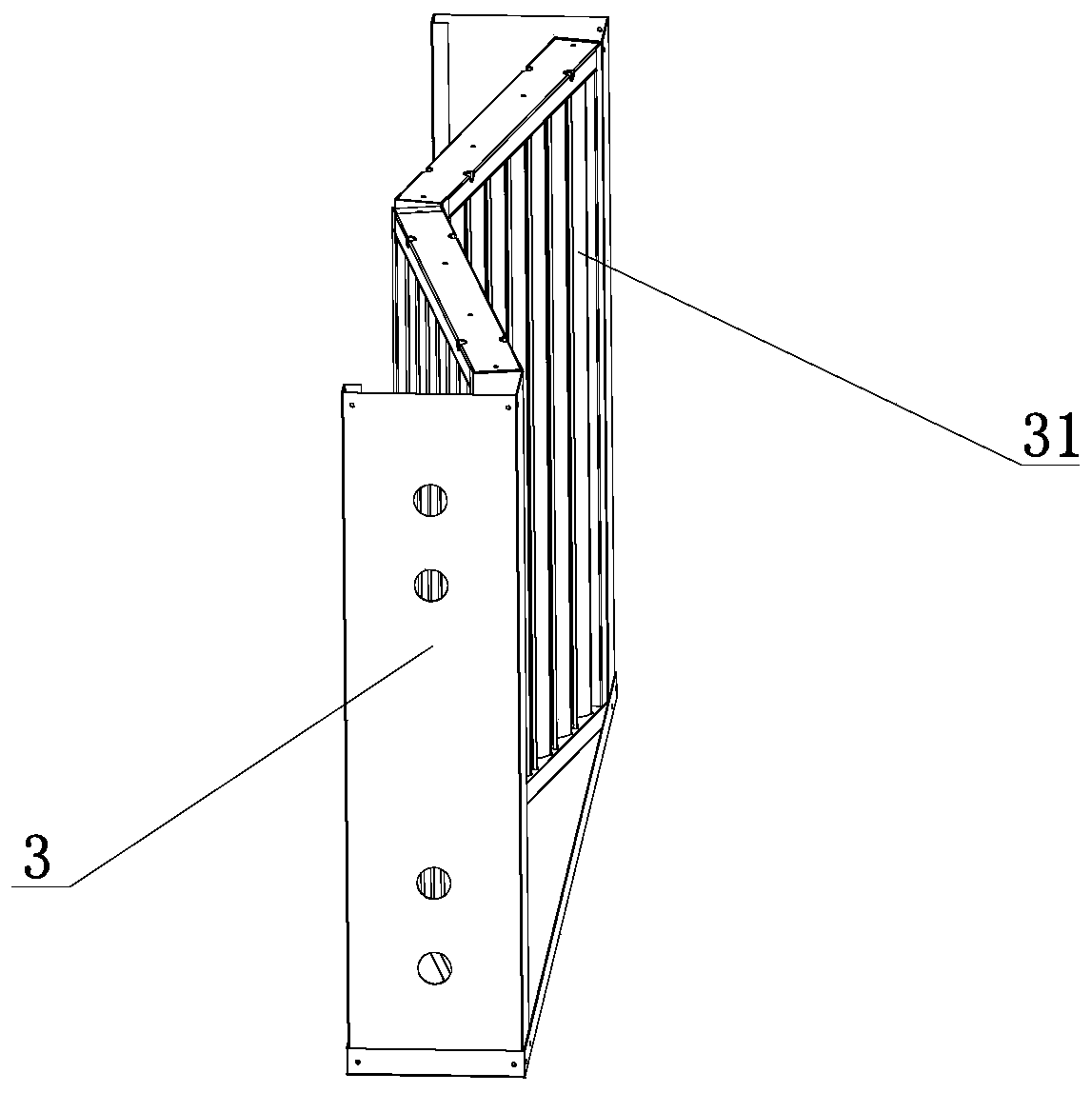

[0024] Such as Figure 1 to Figure 8 As shown, the non-consumable fixed particle flue gas solid particle processing equipment in this embodiment includes a box body 1 with an air inlet 11 and an air outlet 12 on both sides, and the box body 1 is located between the air inlet 11 and the air outlet 12 A mechanical collision assembly 2, an airflow collision assembly 3, a spray assembly 4, a fixed particle interception assembly 5, and a gas-liquid separation assembly 6 are arranged in sequence on one side. The mechanical collision assembly 2 also includes a collision frame 22, which is connected with two inclined Arranged collision frame 21, the inclined arrangement of collision frame 21 can greatly increase the contact area and improve the processing efficiency. Ventilation holes 211 are set on both sides of collision frame 21, and the ventilation holes 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com