Technology of heavy oil floating bed hydrocracking

A hydrocracking and suspension bed technology, which is applied in the fields of hydroprocessing, petroleum industry, and hydrocarbon oil treatment, can solve the problems of poor adaptability, poor product quality, and high investment cost, and achieve the effect of reducing the content of solid particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

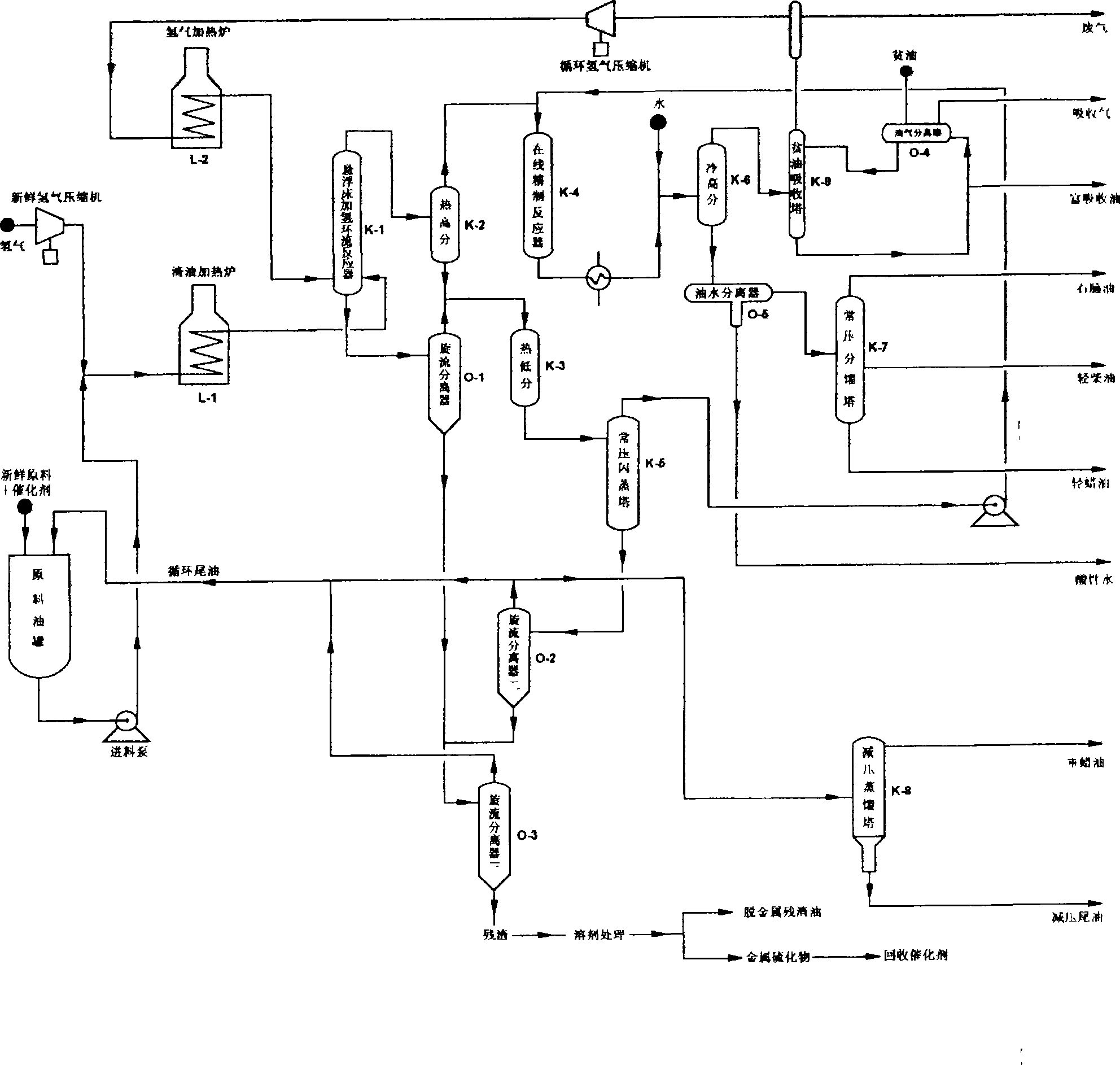

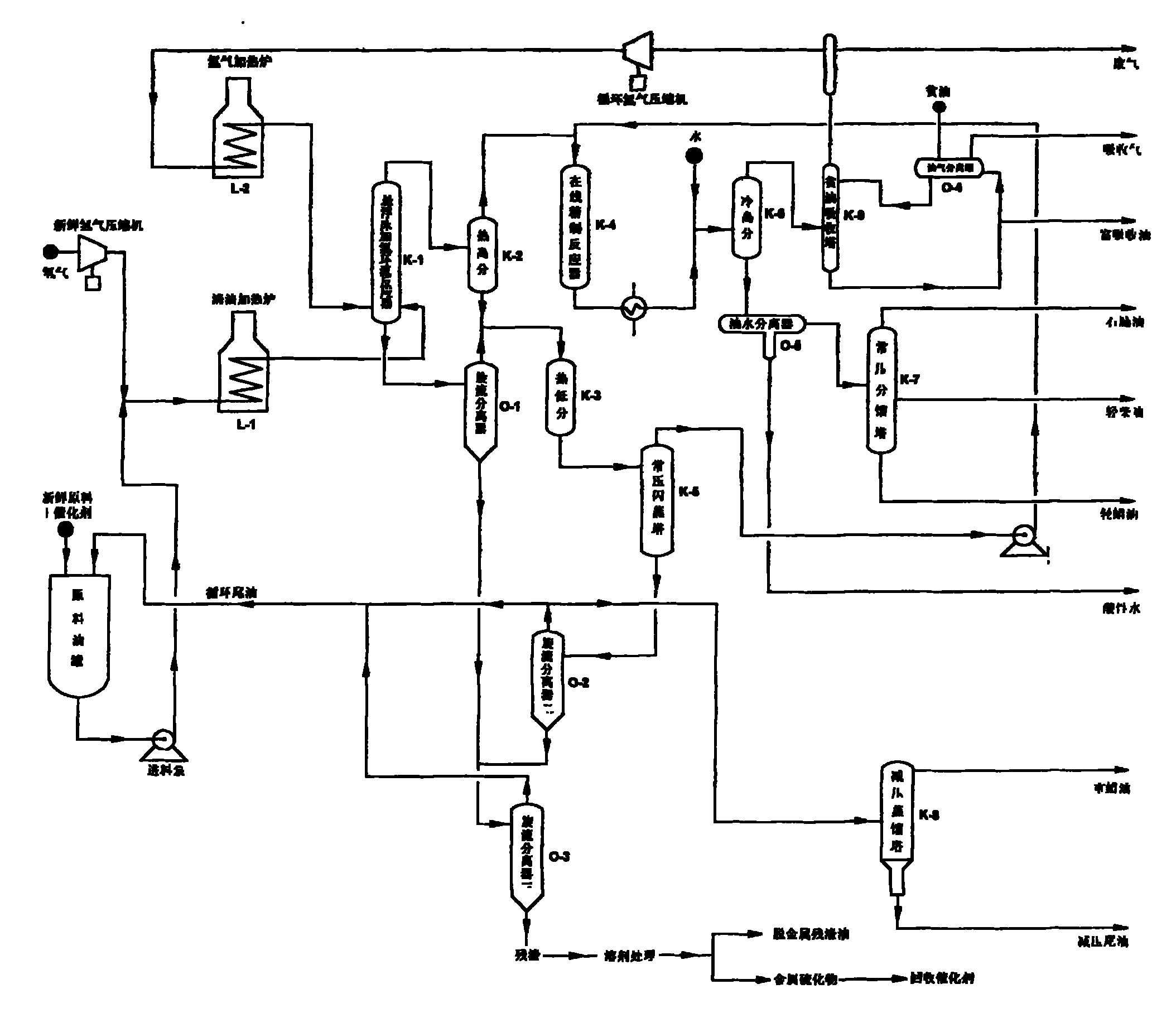

[0020] The design ideas and design advantages of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] In actual design and operation, the designer of the present invention adopts the technical process as shown in the accompanying drawing, and has used highly dispersed polymetallic composite liquid catalyst (UPC series) in the suspended bed hydrocracking loop reactor, in The 3936 or 3996 or RN-2 hydrorefining catalyst commonly used in industry is used in the fixed bed hydrorefining reactor. In this way, the raw material residue (containing highly dispersed and low-temperature vulcanized catalyst) is mixed with wax oil or circulating tail oil (the raw material residue may not be mixed with wax oil or tail oil and adopts a one-pass process) and then re-processed by the feed pump. It is mixed with fresh hydrogen and enters the residual oil heating furnace L-1. After being heated to 380-480°C, it enters from the bottom (or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com