Stacking robot

A robot and palletizing technology, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of slow driving speed of oil cylinders, high power consumption, and high center of gravity, and achieve the effect of rapid action, low power consumption, and low center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

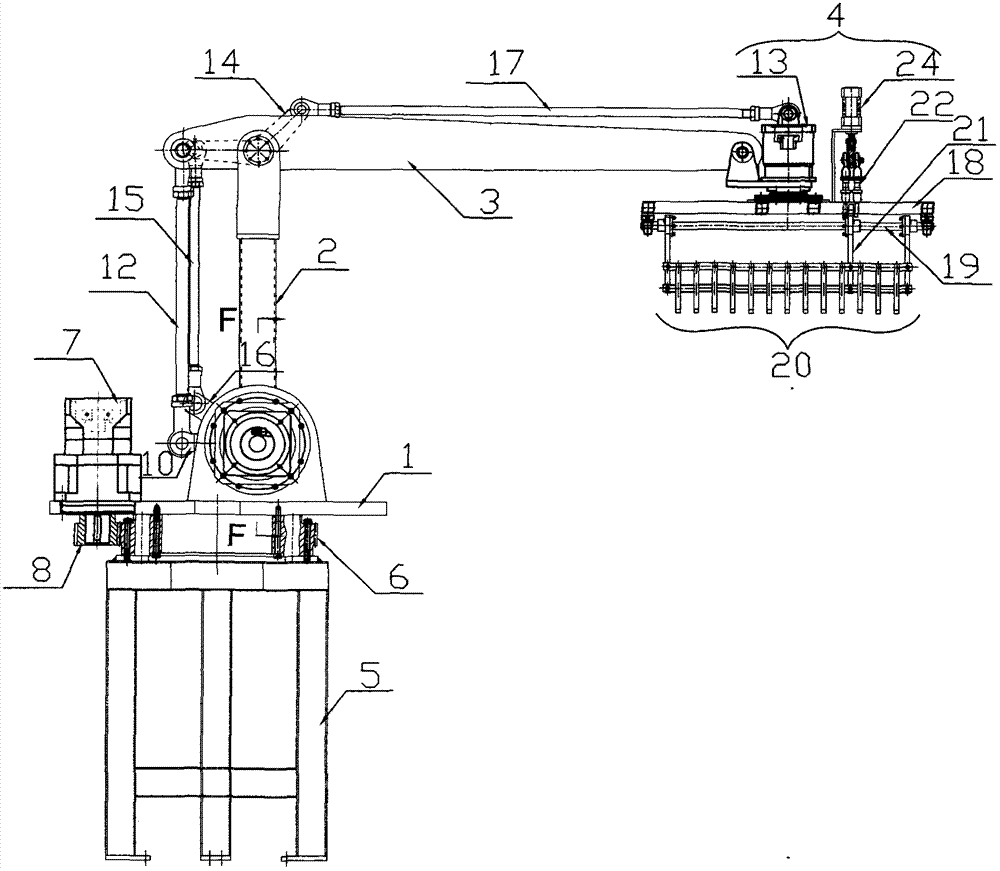

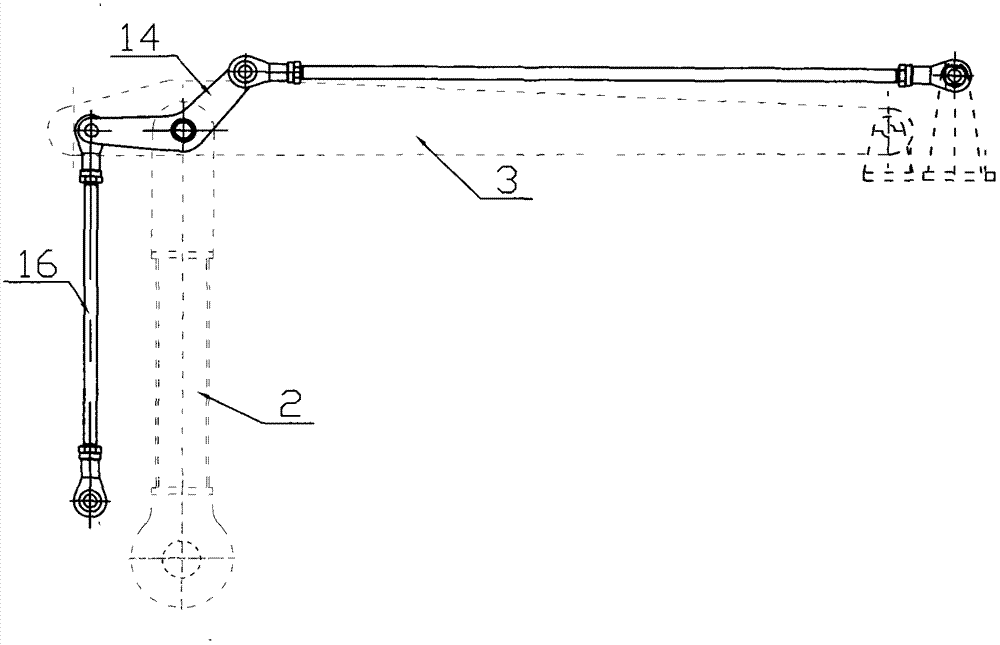

[0023] Implementation mode one: if Figure 1-2 As shown, the palletizing robot includes a base 1, a vertical arm 2, a cross arm 3 and a pick-up device, and the vertical arm 2, the cross arm 3 and the pick-up device are hinged together in sequence, and are equipped with a programmable control circuit (in the figure not shown), the preferred clamping device 4 of the pick-up device is characterized in that:

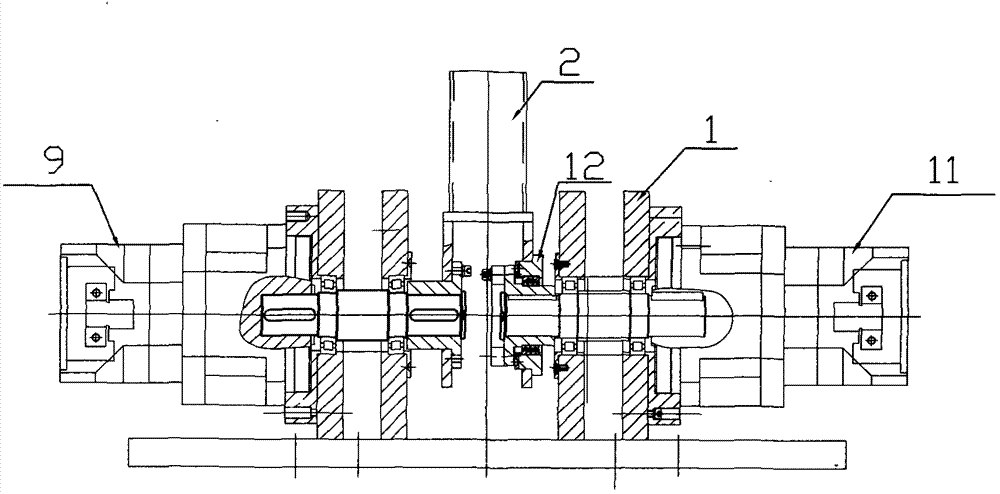

[0024] ①The base 1 is pivotally connected to a bracket 5, the bracket 5 is provided with a horizontal large gear 6, the base 1 is provided with a steering drive motor 7, and the output shaft of the steering drive motor 7 drives a planetary gear 8, the The planetary gear 8 meshes with the horizontal bull gear 6 to form a planetary gear train.

[0025] ②The vertical arm 2 is hinged on the base 1, and the vertical arm 2 can swing under the drive of a vertical arm driving motor 9;

[0026] ③The base 1 is also hinged with a first swing link 10, the first swing link 10 is driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com